Engineering Microbial Chassis for Sustainable Chemical Production: From C1 Utilization to Data-Driven Design

This article explores the engineering of microbial chassis as sustainable platforms for chemical production, targeting researchers and scientists in drug development and biotechnology.

Engineering Microbial Chassis for Sustainable Chemical Production: From C1 Utilization to Data-Driven Design

Abstract

This article explores the engineering of microbial chassis as sustainable platforms for chemical production, targeting researchers and scientists in drug development and biotechnology. It covers the foundational principles of utilizing diverse microbes, including non-traditional hosts, for converting waste gases and renewable feedstocks into high-value chemicals. The scope extends to advanced methodological strategies in metabolic engineering and synthetic biology, addresses key troubleshooting and optimization challenges such as host-circuit interference and low carbon yield, and validates approaches through techno-economic analysis and comparative performance assessments. The synthesis aims to provide a comprehensive roadmap for developing efficient microbial cell factories that support a circular bioeconomy.

What is a Microbial Chassis? Foundations for a Sustainable Production Revolution

The concept of a microbial chassis is central to modern industrial biotechnology and synthetic biology. In the context of sustainable chemical production, a microbial chassis is an engineered organism that provides the foundational platform for housing biosynthetic pathways to produce value-added chemicals from renewable resources [1]. This paradigm shift from petrochemical-based production to bio-based manufacturing relies on the rational selection and optimization of these biological workhorses. The ideal chassis serves as a streamlined cell factory, designed for optimal functionality, genetic stability, and metabolic efficiency to maximize the production of target compounds while minimizing industrial costs and environmental impact [2] [3]. The transition from a limited set of model organisms to a diverse array of specialized hosts represents a significant evolution in the field, enabling more sophisticated and efficient bioproduction strategies for a sustainable economy.

Model vs. Non-Model Microbial Chassis

The conventional approach in synthetic biology has heavily favored model microorganisms, primarily Escherichia coli and Saccharomyces cerevisiae, due to their well-characterized genetics, rapid growth rates, and the extensive availability of synthetic biology tools [1] [4]. These chassis have been instrumental in demonstrating proof-of-concept systems and producing a wide range of high-value chemicals and proteins [1] [3]. E. coli, for instance, can dedicate nearly 40% of its dry cell weight to recombinant protein production under fed-batch conditions [3]. However, inherent limitations such as the lack of complex post-translational modification machinery, sensitivity to toxic compounds, and suboptimal metabolic networks for certain biosynthetic pathways have constrained their applicability [1] [3].

To overcome these bottlenecks, there is a growing emphasis on developing non-model microbial chassis selected for their peculiar advantages in metabolic networks and biosynthesis [1] [2]. This emerging subdiscipline, termed Broad-Host-Range (BHR) synthetic biology, reconceptualizes host selection as an active design parameter rather than a passive platform [4]. By leveraging innate host traits, synthetic biologists can "hijack" nature's solutions for challenging production environments and complex biochemistry, often achieving higher yields and functionality than possible in traditional model systems [4].

Table 1: Comparison of Model and Non-Model Microbial Chassis

| Chassis Type | Examples | Advantages | Limitations | Ideal Applications |

|---|---|---|---|---|

| Model Organisms | Escherichia coli,Saccharomyces cerevisiae | - Extensive genetic toolkits- Rapid growth- Well-characterized physiology- High recombinant protein yield [3] | - Limited post-translational modifications- Sensitivity to toxins and harsh conditions- Metabolic mismatches for some pathways [1] [3] | - Rapid pathway prototyping- Production of non-glycosylated proteins- High-value chemicals [1] [5] |

| Non-Model Specialized Chassis | Pseudomonas putida,Bacillus subtilis,Yarrowia lipolytica,Streptomyces spp.,Lactic Acid Bacteria (LAB) [1] [6] | - Native stress tolerance (e.g., high salinity, solvents)- Specialized metabolic capabilities- Superior protein secretion (e.g., B. subtilis) [1] [4] [6] | - Less developed genetic tools- Longer development timelines- Less predictable genetic device performance [1] [2] | - Bioremediation- Production of complex natural products (PKs, NRPs, RiPPs) [1]- Industrial-scale fermentation under harsh conditions [4] |

Quantitative Performance of Engineered Chassis

The effectiveness of a microbial chassis is ultimately quantified by its production metrics. Automated biofoundries have demonstrated the capability for rapid prototyping, successfully constructing E. coli strains to produce 17 target material monomers within an 85-day period by assembling 160 genetic parts into 115 unique biosynthetic pathways [5]. The table below summarizes the production capabilities for a selection of these compounds, highlighting the competitive titers achievable through streamlined DBTL cycles.

Table 2: Production Metrics for Material Monomers in an Engineered E. coli Chassis [5]

| Target Compound | Compound Class | Days to Production | Titer (mg/L) | Yield (g/g) | Genes Required |

|---|---|---|---|---|---|

| Cinnamic acid | Phenylacrylic acids | 30 | 669 ± 59 | 0.17 | 1 |

| Coumaric acid | Phenylacrylic acids | 30 | 405 ± 64 | 0.09 | 1 |

| Styrene | Vinylbenzenes | 45 | 318 ± 3 | 0.08 | 3 |

| 4-Vinylguaiacol | Vinylbenzenes | 45 | 504 ± 24 | 0.87 | 5 |

| Muconic acid | Muconic acid | 84 | 31 ± 16 | 0.01 | 5 |

| Eugenol | Allylbenzenes | 80 | 102 ± 17 | 0.18 | 8 |

For specialized compounds, non-model chassis show distinct advantages. The oleaginous yeast Yarrowia lipolytica is a superior chassis for producing microbial-derived oils and usual/unusual fatty acids due to its innate metabolic capabilities [1]. Furthermore, the high-salinity tolerance of Halomonas bluephagenesis makes it an ideal chassis for open, non-sterile bioprocessing, significantly reducing industrial operational costs [4].

Experimental Protocols for Chassis Development and Evaluation

Protocol 1: Automated Design-Build-Test-Learn (DBTL) Cycle for Rapid Strain Prototyping

This protocol outlines the pipeline for the rapid development of production strains, as benchmarked for material monomers [5].

Design Phase

- Target Identification: Select a desired chemical building block.

- Retrosynthetic Biological Design: Use computational tools (e.g., RetroPath2.0) to explore known and putative biochemical pathways from host metabolism to the target compound.

- DNA Design: Select enzyme-coding sequences (wild-type or engineered) for each reaction step. Design genetic constructs with appropriate promoters, RBSs, and terminators for the chosen host.

Build Phase

- DNA Synthesis: Synthesize gene fragments or codon-optimized genes.

- Automated Pathway Assembly: Use robotic platforms (e.g., BioXp) to assemble multiple genetic pathways in parallel via standardized methods (e.g., Golden Gate Assembly, Gibson Assembly).

- Chassis Transformation: Introduce the assembled constructs into the microbial host (e.g., E. coli for prototyping) via electroporation or chemical transformation.

Test Phase

- High-Throughput Cultivation: Grow engineered strains in deep-well plates with defined media under controlled conditions.

- Metabolite Screening: Use high-performance liquid chromatography (HPLC) or liquid chromatography-mass spectrometry (LC-MS) to quantify target compound production and key metabolites.

- Data Collection: Record titers (mg/L), yields (g product/g substrate), and productivity.

Learn Phase

- Data Analysis: Identify top-performing pathway variants and chassis strains.

- Iterative Redesign: Use performance data to inform the next DBTL cycle, which may involve enzyme engineering, promoter/RBS tuning, or host engineering to eliminate bottlenecks.

Protocol 2: Genome Reduction for Streamlined Chassis Construction

This protocol describes a computational and experimental approach for creating minimal genome chassis with improved properties [6].

Step 1: Genome Annotation and Model Construction

- Annotate the host genome using automated pipelines (e.g., Prokka, RAST) followed by manual curation to identify all functional elements.

- Construct a Genome-Scale Metabolic (GSM) model to map the organism's metabolic network and predict gene essentiality.

Step 2: Prediction of Gene Essentiality

- Use computational tools (e.g., Traitar, DEG) to predict essential genes based on homology.

- Conduct in silico gene knockout simulations using the GSM model under the target growth and production conditions to identify dispensable genes.

Step 3: Design of Deletion Strategy

- Select large genomic regions for deletion that are rich in non-essential genes, such as prophages, genomic islands, and insertion sequences.

- Design deletion constructs with selectable markers flanked by homology arms targeting the regions of interest.

Step 4: Sequential Genome Deletion

Step 5: Phenotypic Characterization

- Assess the fitness of the genome-reduced strain by measuring growth rate, biomass yield, and substrate consumption.

- Test the strain's performance as a production chassis for the target heterologous pathway, comparing titers and yields to the parental strain.

The Scientist's Toolkit: Essential Research Reagents and Solutions

The engineering of advanced microbial chassis relies on a suite of synthetic biology tools and reagents. The following table details key resources for chassis construction and optimization.

Table 3: Research Reagent Solutions for Microbial Chassis Engineering

| Reagent / Tool Category | Specific Examples | Function & Application |

|---|---|---|

| Genetic Parts & Vectors | SEVA (Standard European Vector Architecture) plasmids, BHR promoters and origins of replication [4] | Modular plasmid systems for reliable gene expression across diverse bacterial hosts, facilitating BHR synthetic biology. |

| Genome Editing Systems | Host-specific CRISPR/Cas systems (e.g., for Corynebacterium, Bacillus), bacteriophage recombinase systems (e.g., Redαβ) [1] [2] | Enable precise, trackable genome editing (knockouts, insertions, replacements) in both model and non-model chassis. |

| Chassis Engineering Strains | E. coli Origami (for disulfide bond formation), B. subtilis WB600 (protease-deficient), E. coli Rosetta (for rare codons) [3] | Specialized host strains designed to overcome common hurdles in heterologous protein expression and metabolic engineering. |

| Pathway Assembly Kits | Golden Gate Assembly MoClo kits, Gibson Assembly master mixes | Standardized, high-efficiency methods for the modular assembly of multi-gene biosynthetic pathways. |

| Analytical & Screening Tools | HPLC, LC-MS, Microplate Readers | For high-throughput quantification of target compound production, metabolite analysis, and growth phenotyping during the Test phase of DBTL cycles. |

| Computational Software | Genome annotation pipelines (e.g., Prokka, RAST), GSM modeling software (e.g., COBRApy), pathway design tools (e.g., RetroPath2.0) [5] [6] | In silico tools for predicting gene function, modeling metabolic fluxes, designing biosynthetic routes, and predicting gene essentiality for genome reduction. |

| TES-991 | TES-991, MF:C17H11N7OS2, MW:393.5 g/mol | Chemical Reagent |

| AA-57 | AA-57, MF:C15H17ClO5, MW:312.74 g/mol | Chemical Reagent |

The field of microbial chassis engineering is dynamically evolving from a reliance on a few model workhorses to the strategic deployment of a diverse portfolio of specialized hosts. This transition, powered by BHR synthetic biology and advanced genome engineering, is fundamental to building a sustainable bio-based economy. By treating the chassis itself as a tunable module, researchers can now select and engineer hosts based on the specific requirements of the target chemical and production process. The integration of automated DBTL cycles, computational modeling, and synthetic biology toolkits will continue to accelerate the design and optimization of these cellular factories. As these technologies mature, the development of highly efficient, specialized microbial chassis will be pivotal in replacing petrochemical-based production with cleaner, renewable biomanufacturing processes, ultimately enabling the sustainable production of a vast array of chemicals, materials, and pharmaceuticals.

The linear fossil fuel-based economy, characterized by a 'take-make-dispose' model, is a primary driver of climate change and resource depletion [7]. In response, sustainable microbial biomanufacturing presents a paradigm shift by using engineered biological systems to convert renewable or waste-based feedstocks into valuable chemicals, materials, and fuels. This transition is central to de-fossilizing the chemical industry and fostering a circular carbon economy, where waste greenhouse gases (GHGs) are recycled into valuable products [7] [8].

Microbial cell factories—engineered microorganisms such as bacteria and yeasts—serve as the core bio-catalysts in this new paradigm. They can be designed to function as efficient chassis strains that transform one-carbon (C1) feedstocks like CO₂, carbon monoxide (CO), methane (CH₄), and methanol (CH₃OH) into target compounds [7] [8]. This approach, often called third-generation (3G) biomanufacturing, avoids competition with food resources and utilizes abundant, and often waste, carbon streams [7]. The overarching goal of this technical guide is to detail the capacities of different microbial chassis, the engineering strategies required to enhance their performance, and the experimental frameworks for developing robust platforms for sustainable chemical production.

Core Feedstocks and Microbial Chassis for C1 Biomanufacturing

Available One-Carbon (C1) Feedstocks

C1 substrates are preferred feedstocks for sustainable biomanufacturing due to their natural abundance, cost-effectiveness, and potential to mitigate climate change, particularly when sourced as industrial by-products [7]. The primary C1 feedstocks include:

- Carbon Dioxide (COâ‚‚): Sourced directly from the atmosphere or, more commonly, from concentrated point sources like industrial flue gases.

- Carbon Monoxide (CO): Typically obtained from syngas derived from waste gases, such as those from steel mills [7].

- Methane (CHâ‚„): Can be sourced from natural gas or as "stranded methane" from various industrial sources like wastewater treatment plants and landfills [7].

- Methanol (CH₃OH): Can be electrochemically produced from CO₂ using renewable energy [7].

A typical C1 biomanufacturing process involves several stages, including feedstock pre-treatment, bioconversion (or electro-bio-conversion), product separation, and waste management [7].

Evaluation of Industrial Microbial Chassis Strains

Selecting an appropriate microbial host is a critical first step in designing a cell factory. A comprehensive in silico evaluation of five representative industrial microorganisms has provided a systematic framework for this selection by calculating their production capabilities for 235 bio-based chemicals [9].

Table 1: Production Capabilities of Industrial Microbial Chassis for Selected Chemicals

| Target Chemical | Potential Microbial Chassis | Key Engineering Strategy | Reported Outcome |

|---|---|---|---|

| 3-Hydroxypropionic Acid (3-HP) | E. coli, P. putida | Two-stage system from steel mill off-gas; Electro-bio-cascade from COâ‚‚ to methanol to 3-HP [7] | A platform chemical for bioplastics; Routes established at pilot scale [7] |

| Mevalonic Acid | Multiple Chassis | Introducing heterologous enzyme reactions; Cofactor exchange [9] | Yield increased beyond innate metabolic capacity [9] |

| Fatty Acids | Multiple Chassis | Introducing heterologous enzyme reactions; Cofactor exchange [9] | Yield increased beyond innate metabolic capacity [9] |

| Isoprenoids | Multiple Chassis | Introducing heterologous enzyme reactions; Cofactor exchange [9] | Yield increased beyond innate metabolic capacity [9] |

| Poly(3-hydroxybutyrate-co-3-hydroxyvalerate) (PHBV) | E. coli, Ralstonia eutropha, Corynebacterium glutamicum, Halophiles | Enhancing propionyl-CoA precursor supply; Pathway optimization [10] | Biodegradable polymer with improved flexibility and toughness over PHB [10] |

The selection of a chassis often depends on the specific target product and pathway. For instance, the biopolymer PHBV has been successfully produced in various hosts. E. coli is a popular sustainable and tractable microbial chassis with a rapid growth rate and well-understood genetics [10]. Ralstonia eutropha (also known as Cupriavidus necator) is widely employed for its natural ability to produce large quantities of intracellular polymer [10]. Corynebacterium glutamicum, a Gram-positive bacterium, is generally regarded as safe (GRAS) and is a pillar of white biotechnology [10]. Halophiles (salt-loving microorganisms) offer the unique advantage of fermentation under high salinity, which prevents microbial contamination and simplifies downstream processing [10].

Advanced Metabolic Engineering and Synthetic Biology Strategies

In Silico Design and Systems-Level Analysis

Overcoming the limitations of traditional, trial-and-error metabolic engineering is now possible with genome-scale metabolic models (GEMs). These computational models reconstruct the entire metabolic network of an organism from its genome, enabling the systematic analysis of metabolic fluxes through computer simulations [9]. This in silico approach revolutionizes strain selection and pathway design by identifying optimal strategies before costly and time-consuming wet-lab experiments [9].

Using GEMs, researchers can quantitatively identify the relationships between specific enzyme reactions and target chemical production. This allows for the determination of which enzyme reactions should be up- or down-regulated to achieve high theoretical yields and maximize production capacity [9]. For more complex systems, computational tools like OptCouple have been adapted to identify strategies for increased product yields not just in single strains, but in community cohorts of microbes, such as syntrophic co-cultures of E. coli [11].

Key Engineering Strategies for Pathway Optimization

- Introducing Heterologous Pathways: A primary strategy involves importing efficient enzyme reactions from other organisms to expand the innate metabolic capabilities of the chassis strain. This is often necessary for enabling C1 assimilation or producing novel compounds [9].

- Cofactor Engineering: Exchanging or modifying the cofactors (e.g., NADH/NADPH) used by microbial enzymes can significantly improve flux through a desired pathway and increase overall yield [9].

- Protease Deletion to Enhance Stability: Recombinant protein degradation by endogenous host proteases is a major hurdle. Systematic knockout of non-essential protease genes is a proven strategy to enhance the accumulation of heterologous proteins. For example, in Thermus thermophilus, the deletion of ten protease loci in the DSP9 strain reduced extracellular proteolytic activity and improved reporter protein accumulation [12].

- Promoter Engineering for Strong Expression: Maximizing protein production requires strong, well-characterized constitutive promoters. Screening of endogenous promoter regions in non-model chassis, such as identifying the P0984 promoter in T. thermophilus with 13-fold higher activity than a control, provides essential genetic tools for high-level expression [12].

- Dynamic Pathway Regulation: Advanced engineering employs synthetic biology to create circuits for dynamic regulation that can sense metabolic states and automatically adjust pathway fluxes to prevent metabolic imbalance and toxicity, thereby maximizing titer and yield [8].

Experimental Protocols for Chassis Development and Evaluation

Protocol: Systematic Protease Knockout for Improved Protein Yield

Objective: To engineer a microbial chassis with reduced recombinant protein degradation by deleting genes encoding non-essential proteases.

Materials:

- Bacterial Strains: Wild-type T. thermophilus HB27 (or chassis of choice) and a CRISPR-deficient precursor strain (e.g., HB27ΔIII-ABΔI-CΔCRF3) for enhanced transformation efficiency [12].

- Plasmids: A shuttle vector (e.g., pRKP31-AC3) for constructing knockout plasmids via the endogenous CRISPR-Cas system [12].

- Growth Media: Tt medium (8 g/L tryptone, 4 g/L yeast extract, 3 g/L NaCl, and salts) [12].

- Reagents: Phanta Max Super-Fidelity DNA polymerase for PCR, restriction enzymes (BbsI), and a seamless assembly mix for cloning [12].

Methodology:

- In Silico Identification: Use genome annotation to predict and select 16 non-essential protease loci for knockout [12].

- Knockout Plasmid Construction:

- For each target locus, design a spacer matching the target and clone it into the shuttle vector between two BbsI sites [12].

- Amplify two homology direct repair (HDR) template arms from the host genome using PCR and connect them via splicing by overhang extension (SOE) PCR. Clone the resulting HDR template into the linearized plasmid [12].

- Transformation: Introduce the constructed plasmid into the competent CRISPR-deficient T. thermophilus precursor strain using its natural competence system during the mid-log phase of growth [12].

- Screening and Validation: Screen for successful knockout mutants. Characterize the resulting strains for growth rate, extracellular proteolytic activity, and accumulation of a reporter protein (e.g., β-galactosidase) [12].

- Iterative Engineering: Perform iterative cycles of gene deletion based on phenotypic analysis to generate a final strain (e.g., DSP9) with multiple protease deletions, robust growth, and enhanced recombinant protein yield [12].

Protocol: Evaluating C1 Utilization with Techno-Economic Analysis (TEA)

Objective: To assess the economic viability and environmental impact of a C1 biomanufacturing process at an early R&D stage.

Materials:

- Process Data: Validated laboratory or pilot-scale data on yield, energy inputs, and material consumption [7].

- Modeling Software: Process modeling tools like Aspen Plus [7].

- TEA/LCA Software: Specialized software for techno-economic analysis and life cycle assessment.

Methodology:

- Process Modeling: Develop a detailed process model encompassing all unit operations, from feedstock pre-treatment to product purification [7].

- Economic Analysis (TEA):

- Capital Expenditure (CAPEX): Estimate costs for bioreactors, infrastructure, and installation. Low carbon yield is a major driver, as it requires larger-scale infrastructure to offset productivity losses [7].

- Operating Expenditure (OPEX): Estimate costs for C1 raw materials (often >57% of OPEX), utilities, and labor [7].

- Minimum Selling Price (MSP): Calculate the MSP of the target chemical and compare it to the market price of its fossil-based equivalent [7].

- Environmental Analysis (LCA): Evaluate the environmental impact of the process, focusing on carbon footprint and other relevant metrics, to ensure net sustainability benefits [7].

- Sensitivity Analysis: Identify key cost and sustainability drivers (e.g., carbon conversion efficiency, feedstock cost) to guide further research and development [7].

The Scientist's Toolkit: Essential Research Reagents and Materials

Table 2: Key Research Reagent Solutions for Microbial Chassis Engineering

| Reagent / Material | Function in Research | Specific Example / Application |

|---|---|---|

| Genome-Scale Metabolic Model (GEM) | In silico prediction of metabolic fluxes and identification of engineering targets [9] | Comprehensive evaluation of E. coli, S. cerevisiae, B. subtilis, C. glutamicum, and P. putida for 235 chemicals [9] |

| CRISPR-Cas System | Precise genome editing for gene knockouts, insertions, and replacements [12] | Endogenous Type I-B system in T. thermophilus for multiplex protease gene knockout [12] |

| Strong Constitutive Promoters | Driving high-level, stable gene expression of heterologous pathways [12] | P0984 promoter from T. thermophilus showing 13-fold higher activity than a control promoter [12] |

| Shuttle Vector | Plasmid for cloning and genetic manipulation in E. coli, followed by expression in the target chassis [12] | pRKP31 vector used for promoter screening and CRISPR-based editing in T. thermophilus [12] |

| Reporter Protein | Quantifying promoter strength or assessing the success of protein expression strategies [12] | Endogenous β-galactosidase (TTP0042) used as a reporter in T. thermophilus [12] |

| C1 Feedstock Gas Mixture | Providing the sole carbon source for fermentation studies [7] | Steel mill off-gas (containing CO/COâ‚‚) used in a two-stage bioprocess for 3-HP production [7] |

| Verapamil-d3 | Verapamil-d3, MF:C27H38N2O4, MW:457.6 g/mol | Chemical Reagent |

| Kanchanamycin C | Kanchanamycin C, MF:C54H91N3O17, MW:1054.3 g/mol | Chemical Reagent |

Visualization of Workflows and Metabolic Pathways

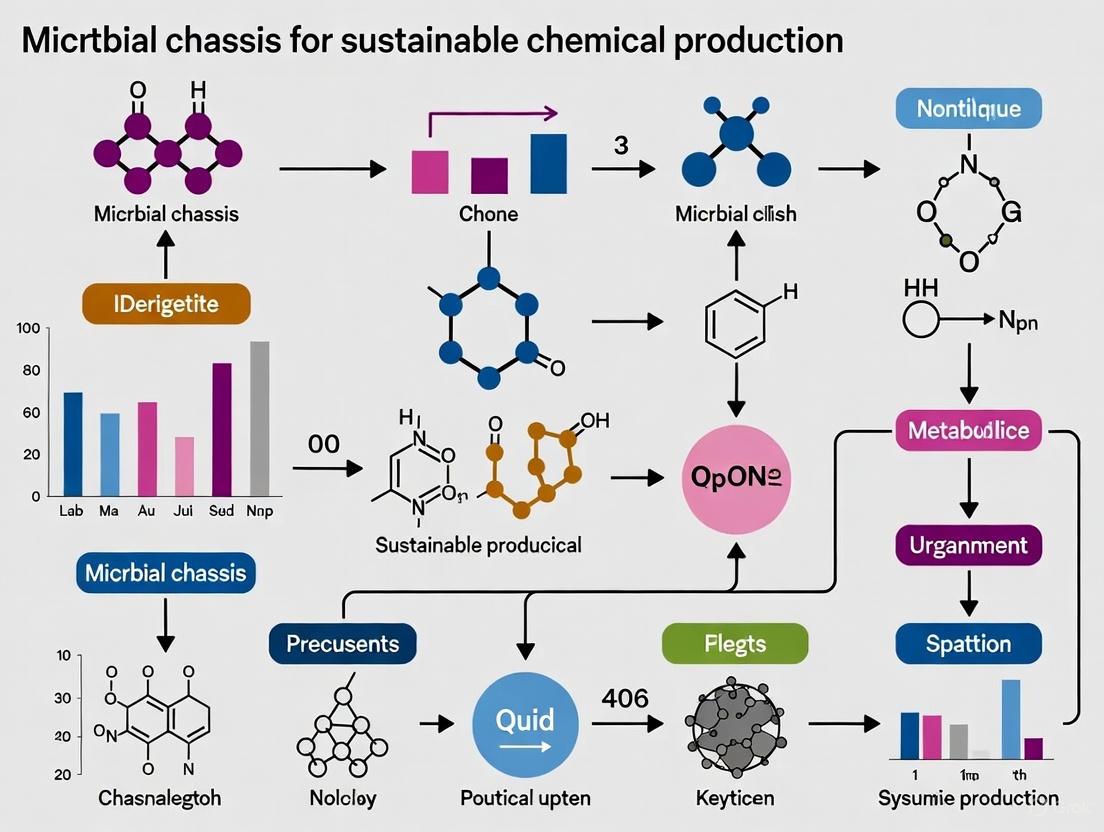

Workflow for Developing a Microbial Cell Factory

The following diagram outlines the core iterative cycle for designing, building, and testing a microbial cell factory for C1 biomanufacturing.

Core Metabolic Pathway for PHBV Biosynthesis

This diagram illustrates the key metabolic pathway for the synthesis of the biopolymer Poly(3-hydroxybutyrate-co-3-hydroxyvalerate) (PHBV) from acetyl-CoA and propionyl-CoA precursors.

The development of microbial cell factories for a circular carbon economy, while promising, faces significant techno-economic barriers. A primary challenge is the low carbon yield of C1 utilization, with feedstock-to-chemical conversion efficiency often below 10%, leading to increased capital and operating expenditures [7]. Furthermore, the decentralized and variable nature of C1 feedstocks, compared to the centralized fossil fuel supply chain, introduces economic risks and complications [7].

Future advancements hinge on the system-level integration of multi-omics data, artificial intelligence (AI)-assisted protein and pathway design, and dynamic metabolic regulation [8]. Continued research into non-model chassis—organisms with innate tolerances to specific feedstocks or conditions—is also crucial. The roadmap to viability involves iterative cycles of experimental validation, guided by robust techno-economic and life cycle assessments, to systematically address these bottlenecks and deliver scalable, economical, and truly sustainable biomanufacturing processes that can replace fossil fuels with circular carbon feedstocks [7].

Synthetic biology has historically operated within a constrained design space, predominantly utilizing a narrow set of well-characterized model organisms such as Escherichia coli and Saccharomyces cerevisiae as chassis platforms [4]. This bias toward traditional organisms has represented a significant design constraint self-imposed by synthetic biologists, leaving the vast chassis-design space an untapped area of engineering potential [4]. Broad-host-range (BHR) synthetic biology has emerged as a modern subdiscipline that aims to alleviate this constraint by systematically expanding chassis selection beyond traditional organisms and reconceptualizing the host as an integral design variable rather than a parameter defaulted to model organisms [4] [13]. This paradigm shift enables researchers to leverage the immense functional diversity found in microbial systems for applications in sustainable biomanufacturing, environmental remediation, and therapeutic development [4].

The core premise of BHR synthetic biology is that host selection fundamentally influences the behavior of engineered genetic systems through mechanisms of resource allocation, metabolic interactions, and regulatory crosstalk [4]. By treating the chassis as an active design component rather than a passive platform, synthetic biologists can access a dramatically expanded engineering space. This approach is particularly valuable for sustainable chemical production, where leveraging organisms with native abilities to utilize waste carbon streams or operate under energy-efficient conditions can significantly improve process economics and environmental footprints [14] [15]. The continued development of BHR tools—including modular genetic vectors, host-agnostic genetic devices, and standardized characterization methods—is now facilitating this expansion of chassis selection, ultimately improving the predictability and stability of engineered biological systems across diverse hosts [4].

Conceptual Framework: Reimagining Microbial Chassis as Design Variables

From Passive Platforms to Active Modules

Contemporary biodesign typically involves introducing genetic machinery into a host organism to confer augmented functionality. The traditional approach focuses optimization efforts almost exclusively on the genetic components (e.g., promoters, RBS, coding sequences) while maintaining the chassis as a fixed element, typically a model organism [4]. In contrast, BHR synthetic biology encourages exploration of both genetic and host contexts simultaneously, positioning the chassis as a modular component that can be rationally selected and optimized [4]. This conceptual shift allows the chassis to serve two distinct but complementary roles:

- Functional Module: The innate biological traits of the chassis are integrated directly into the design concept [4]. For example, native photosynthetic capabilities of cyanobacteria can be rewired for biosynthetic production from COâ‚‚ and sunlight [4] [14], while the natural stress tolerance of extremophiles makes them ideal chassis for processes requiring operation in harsh environmental conditions [4].

- Tuning Module: When circuit function is independent of specific host phenotypes, chassis selection still influences performance specifications through host-environment interactions [4]. Studies have demonstrated that identical genetic circuits exhibit different performance metrics—including output signal strength, response time, and growth burden—when operating in different hosts, providing a spectrum of performance profiles for optimization [4].

This paradigm is visualized in the diagram below, which contrasts the traditional fixed-chassis approach with the BHR modular approach:

The Chassis Effect: Challenge and Opportunity

A fundamental challenge in BHR synthetic biology is the "chassis effect"—the phenomenon where identical genetic constructs exhibit different behaviors depending on the host organism [4]. This context dependency arises from complex host-construct interactions, including resource competition for finite cellular components (e.g., RNA polymerase, ribosomes, metabolites), regulatory crosstalk with endogenous networks, and differences in fundamental cellular machinery [4]. While historically viewed as an obstacle to predictability, the BHR framework reframes this variation as a tunable parameter that can be exploited for system optimization [4].

The chassis effect manifests through multiple mechanisms:

- Resource Allocation: Expression of exogenous genetic elements perturbs host metabolic states, triggering resource reallocation that influences system function [4]. Studies have demonstrated that RNA polymerase flux and ribosome occupancy significantly impact genetic circuit dynamics [4].

- Molecular Interactions: Divergence in promoter–sigma factor interactions, transcription factor structure/abundance, and temperature-dependent RNA folding modulate gene expression profiles across hosts [4].

- Metabolic Burden: Introduced genetic circuits create metabolic burdens that vary between hosts, leading to different growth dynamics and selection pressures [4].

Rather than treating these interactions as noise to be eliminated, BHR synthetic biology seeks to understand and harness them through systematic characterization of host-dependent behaviors and development of predictive models that account for host-context variables [4].

Promising Non-Model Chassis for Sustainable Bioproduction

The expansion of synthetic biology beyond traditional hosts has revealed numerous organisms with specialized metabolic capabilities ideally suited for sustainable chemical production. These organisms often possess native traits that would be difficult or inefficient to engineer into model hosts, representing opportunities for "hijacking" natural adaptations for biotechnological applications [4]. The table below summarizes key non-model chassis and their relevant applications:

Table 1: Promising Non-Model Chassis Organisms for Sustainable Bioproduction

| Chassis Organism | Native Characteristics | Biotechnological Applications | Engineering Challenges |

|---|---|---|---|

| Cyanobacteria (Synechococcus spp., Synechocystis spp.) | Photoautotrophic growth, COâ‚‚ fixation [4] [14] | Production of fuels and chemicals from COâ‚‚ [4] [14] [15] | Genetic toolbox maturity, low growth rates, low product titers [14] |

| Halomonas bluephagenesis | High salinity tolerance, natural product accumulation [4] | Large-scale fermentation without sterile conditions, biopolymer production [4] | Genetic accessibility, parts characterization [4] |

| Rhodopseudomonas palustris | Metabolic versatility, four distinct metabolic modes [4] | Growth-robust chassis for diverse carbon sources [4] | Complex regulation, metabolic network understanding [4] |

| Thermophiles (Geobacillus spp., Thermus spp.) | High-temperature tolerance, robust enzymes [4] | Industrial processes with high temperatures, consolidated bioprocessing [4] | DNA delivery methods, genetic tools, host-adapted parts [4] |

| Methylotrophic Yeasts (Komagataella phaffii) | Methanol assimilation, strong promoters, eukaryotic processing [16] | Recombinant protein production, C1 substrate utilization [16] | Pathway regulation, co-factor balancing [16] |

| Actinobacteria (Streptomyces spp.) | Secondary metabolism proficiency, natural product diversity [17] | Heterologous production of specialized metabolites [17] | Complex life cycle, genetic manipulation efficiency [17] |

The selection of an appropriate chassis depends on application-specific requirements, including not just device performance but also ecological, metabolic, and operational contexts [4]. For sustainable chemical production, key considerations include carbon source utilization, energy efficiency, operational stability, and compatibility with downstream processing [16] [15].

Chassis for Carbon Utilization and Circular Bioeconomy

Microbial conversion of sustainable carbon streams represents a cornerstone of circular bioeconomy strategies [14] [15]. Different chassis offer distinct advantages for specific carbon sources:

- C1 Gas Utilization: Native autotrophs such as cyanobacteria and hydrogen-oxidizing bacteria provide platforms for direct COâ‚‚ and CO conversion [14] [15]. Recent engineering efforts have also introduced autotrophic capabilities into industrially-relevant heterotrophic hosts, creating hybrid systems that combine carbon fixation with high-productivity traits [14].

- Waste Carbon Valorization: Organisms with native abilities to consume industrial byproducts and waste streams (e.g., glycerol, acetate, aromatics, methane) enable valorization of low-cost feedstocks [15]. Rhodopseudomonas palustris exemplifies this approach with its metabolic versatility across diverse carbon sources [4].

- Sugar Biorefining: While traditional hosts dominate this space, non-model organisms may offer advantages for specific carbohydrate streams, particularly those from lignocellulosic biomass that contain inhibitor compounds [15].

The diagram below illustrates the dual functional roles of microbial chassis in BHR synthetic biology:

Technical Implementation: Tools and Methodologies for BHR Engineering

Broad-Host-Range Genetic Toolkits

The practical implementation of BHR synthetic biology requires genetic tools that function across diverse hosts. Key developments include:

- Modular Vector Systems: Platforms such as the Standard European Vector Architecture (SEVA) provide modular parts with BHR compatibility, including origins of replication, selection markers, and cargo elements that can be interchanged for different hosts [4].

- Host-Agnostic Genetic Parts: Efforts to characterize and engineer genetic parts (promoters, RBS, terminators) with consistent function across taxonomic groups reduce context dependency and improve predictability [4].

- Synthetic Biology Standards: Development of shared standards, including the Synthetic Biology Open Language (SBOL), facilitates exchange of genetic designs and experimental data across different host systems [18].

Table 2: Essential Research Reagents for BHR Synthetic Biology

| Reagent Category | Specific Examples | Function/Application | Implementation Considerations |

|---|---|---|---|

| Vector Systems | SEVA vectors, RK2-based plasmids [4] | DNA maintenance across diverse hosts | Origin of replication host range, selection marker compatibility |

| Genetic Parts | Synthetic promoters, ribosomal binding sites [4] | Control of gene expression levels | Part characterization across hosts, orthogonality to host systems |

| Editing Tools | CRISPR-Cas systems, recombineering [17] | Genome modification and engineering | Host compatibility, delivery efficiency, repair mechanism differences |

| Characterization Tools | Fluorescent reporters, biosensors [4] | Measurement of gene expression and metabolic states | Reporter stability, host-specific interference, measurement compatibility |

| Computational Tools | Whole-cell models, host-circuit models [4] [19] | Prediction of system behavior | Model parameterization for non-model hosts, resource allocation prediction |

| Isopersin | Isopersin, MF:C23H40O4, MW:380.6 g/mol | Chemical Reagent | Bench Chemicals |

| Angiolam A | Angiolam A, MF:C34H53NO7, MW:587.8 g/mol | Chemical Reagent | Bench Chemicals |

Experimental Workflow for Chassis Characterization and Selection

Implementing a BHR approach requires systematic methodology for evaluating host performance. The following workflow provides a framework for chassis selection and engineering:

Protocol: Cross-Host Characterization of Genetic Devices

Objective: Quantitatively compare performance of standardized genetic devices across multiple microbial hosts to identify host-dependent effects and select optimal chassis for specific applications.

Materials:

- Reference Genetic Devices: Standardized constructs encoding fluorescent reporters (e.g., GFP, RFP) under control of well-characterized inducible promoters [4]

- Host Strains: Selected candidate chassis organisms with relevant metabolic features [4] [14]

- Transformation Reagents: Host-specific DNA delivery methods (electroporation, conjugation, chemical transformation) [17]

- Culture Conditions: Defined media matching application requirements (e.g., minimal media with target carbon sources) [16] [15]

- Analytical Equipment: Plate reader with temperature control and shaking capability, flow cytometer, RNA sequencing capability [4]

Methodology:

- Genetic Tool Adaptation:

Standardized Cultivation:

- Inoculate triplicate cultures of each transformed host in defined media

- Grow under controlled conditions with monitoring of optical density (OD600)

- Induce expression at mid-exponential phase using standardized inducer concentrations [4]

Multi-Level Characterization:

- Device Performance: Measure fluorescence intensity at single-cell and population levels using flow cytometry and plate reading [4]

- Host Response: Transcriptomic analysis (RNA-seq) to assess host responses to device expression [4]

- Resource Impact: Quantify growth rate changes, biomass yield, and metabolic byproducts [4]

Data Integration and Modeling:

Expected Outcomes: This protocol generates quantitative, comparable data on device performance across hosts, enabling rational chassis selection based on application-specific requirements such as expression strength, response dynamics, and metabolic burden [4].

Applications in Sustainable Chemical Production

BHR synthetic biology enables innovative approaches to sustainable manufacturing by matching production challenges with appropriate microbial hosts. Promising applications include:

Carbon-Negative Biomanufacturing: Engineering cyanobacteria and other autotrophic hosts for direct conversion of COâ‚‚ to chemicals and fuels represents a carbon-negative manufacturing platform [14] [15]. Recent advances have improved the growth kinetics and bioproduction capabilities of these native autotrophs while also introducing autotrophic metabolism into industrially-relevant heterotrophic hosts [14].

Waste Stream Valorization: Non-model chassis with native abilities to consume industrial byproducts and waste carbon streams enable circular economy approaches [15]. For example, methylotrophic yeast platforms can convert methanol into higher-value chemicals, while organisms capable of aromatic compound metabolism can valorize lignin derivatives [15].

Robust Industrial Processing: Extremophilic chassis (thermophiles, halophiles, acidophiles) enable bioprocessing under conditions that minimize contamination risk, reduce cooling costs, and simplify product recovery [4]. Halomonas bluephagenesis, with its high salinity tolerance, allows for large-scale fermentation without strict sterility requirements [4].

Specialized Metabolites Production: Activation of cryptic biosynthetic gene clusters through heterologous expression in optimized actinobacterial chassis enables discovery and production of novel bioactive compounds [17]. Genome streamlining of these hosts reduces metabolic complexity and improves product yields by minimizing interference with native metabolism [17].

Future Perspectives and Concluding Remarks

The continued expansion of synthetic biology into non-model hosts represents both a paradigm shift and practical necessity for achieving truly sustainable biomanufacturing. Several emerging technologies are poised to accelerate this transition:

Automation and Digitalization: Biofoundries and automated workflow platforms are increasingly supporting engineering of non-model hosts through high-throughput design-build-test-learn cycles [19]. These platforms enable systematic characterization of genetic parts across multiple hosts, generating the data needed for predictive design [19].

Deep Learning for DNA Design: Machine learning approaches applied to biological sequence analysis show promise for designing host-agnostic genetic elements that function predictably across diverse chassis [19]. As these models improve, they may reduce the empirical optimization currently required for each new host [19].

Whole-Cell Models and Simulations: Advances in systems biology are progressing toward comprehensive whole-cell models that can simulate how genetic constructs will function in different host environments [19]. These computational tools would enable in silico chassis selection and reduce experimental bottlenecks [19].

Community-Based Bioprocessing: The use of microbial consortia, where different organisms division metabolic labor, represents an extension of the BHR concept [11]. Computational tools like OptCouple are being developed to identify synergistic community designs with increased product yields [11].

In conclusion, broad-host-range synthetic biology represents a maturation of the field beyond its foundational model organisms toward a more sophisticated engineering discipline that embraces biological diversity as a design feature. By strategically selecting and engineering microbial chassis based on application requirements rather than historical convenience, researchers can develop more efficient, sustainable, and robust bioprocesses for chemical production. As tool development continues and our understanding of host-context effects deepens, the systematic exploration of chassis space will undoubtedly yield innovative solutions to pressing sustainability challenges.

The transition from a linear, fossil-based economy to a circular bioeconomy represents a paramount challenge for the chemical industry. One-carbon (C1) feedstocks—primarily carbon dioxide (CO₂), carbon monoxide (CO), and methane (CH₄)—are emerging as pivotal substrates in this transformation, enabling sustainable microbial production of fuels and chemicals. C1 compounds are naturally abundant, can be sourced from industrial waste gases and the atmosphere, and their utilization for biomanufacturing presents a pathway to defossilize chemical production and foster a circular carbon economy by recycling waste greenhouse gases [7].

This paradigm, termed third-generation (3G) biomanufacturing, focuses on converting these C1 compounds into value-added products using engineered biological systems, primarily microbial cell factories [8] [7]. Unlike first- or second-generation processes that use sugar or lignocellulosic biomass, C1 biomanufacturing avoids competition with food resources and directly leverages greenhouse gases as carbon substrates [8]. The core of this technology relies on the engineering of natural or synthetic microbial chassis—host organisms—to efficiently assimilate C1 molecules and redirect cellular resources toward desired biosynthetic pathways, a process accelerated by advanced synthetic biology and systems metabolic engineering [14] [20].

Core C1 Feedstocks and Microbial Assimilation Pathways

Feedstock Characteristics and Sourcing

The principal C1 feedstocks for biomanufacturing are CO₂, CO, and CH₄, along with derived molecules like methanol (CH₃OH) and formate. Their characteristics and typical sources are summarized in Table 1.

Table 1: Key C1 Feedstocks for Microbial Biomanufacturing

| Feedstock | Chemical Formula | Primary Sources | Key Characteristics & Challenges |

|---|---|---|---|

| Carbon Dioxide | COâ‚‚ | Atmosphere, industrial off-gases (e.g., fermentation exhaust), flue gas [7] [21]. | Highly oxidized; requires significant energy input for reduction; low energy content [21]. |

| Carbon Monoxide | CO | Syngas from gasified waste, steel mill off-gas [7]. | Toxic to many organisms; high energy content as it is more reduced than COâ‚‚ [7]. |

| Methane | CHâ‚„ | Natural gas, biogas from anaerobic digestion, stranded methane from landfills and wastewater [7] [20]. | Low solubility in aqueous solutions; challenging to activate and functionalize [7]. |

| Methanol | CH₃OH | Electrochemical conversion of CO₂, synthetic natural gas processes [7] [21]. | Liquid at room temperature; easier to handle and store; can be produced renewably [21]. |

| Formate | HCOOH | Electrochemical conversion of COâ‚‚ [21]. | High water solubility; can serve as both a carbon source and an electron donor [21]. |

A significant hurdle for industrialization is the variable and decentralized nature of C1 resources compared to the centralized crude oil supply chain. For instance, the production of stranded CHâ‚„ from various U.S. industrial sources varies from less than one ton per day at wastewater treatment plants to an average of 31 tons per day at landfills [7]. This variability introduces economic risks and challenges related to economies of scale.

Native and Engineered C1 Assimilation Pathways

Microorganisms have evolved several natural pathways to fix and assimilate C1 compounds. Engineering these pathways into industrially robust microbial chassis is a primary focus of synthetic biology. The major natural pathways include:

- The Calvin-Benson-Bassham (CBB) Cycle: Used by cyanobacteria, algae, and plants, this cycle fixes COâ‚‚ using the enzyme RuBisCO. It is the most common but not the most energetically efficient pathway [22] [21].

- The Wood-Ljungdahl Pathway (WLP): Used by acetogenic bacteria (e.g., Clostridium autoethanogenum), this anaerobic pathway is highly energy-efficient. It can utilize both COâ‚‚ and CO as carbon sources, with Hâ‚‚ as an electron donor, making it ideal for syngas fermentation [23] [22].

- The Reductive Tricarboxylic Acid (rTCA) Cycle: Found in some anaerobic bacteria and archaea, this pathway is highly efficient in terms of ATP cost and is adaptable across a broad range of COâ‚‚ and Hâ‚‚ concentrations [23].

- The 3-Hydroxypropionate/4-Hydroxybutyrate (HP/HB) Cycle and the 3-Hydroxypropionate (3HP) Bicycle: Found in certain archaea, these pathways are capable of generating large thermodynamic driving forces, which can be advantageous for production [23].

Table 2: Comparison of Key Natural COâ‚‚ Fixation Pathways

| Pathway | Representative Microbes | Energy Efficiency (ATP per pyruvate) | Key Advantages | Key Disadvantages |

|---|---|---|---|---|

| Calvin Cycle | Cyanobacteria, Cupriavidus necator | 7 ATP | Well-studied; versatile; can be engineered into heterotrophs. | Low catalytic efficiency of RuBisCO; high energy cost. |

| Wood-Ljungdahl Pathway | Acetogens (e.g., Clostridium), Methanogens | 0-1 ATP [23] | Highest known energy efficiency; operates anaerobically. | Strict anaerobiosis; complex gas requirements (CO/COâ‚‚/Hâ‚‚). |

| Reductive TCA Cycle | Some green sulfur bacteria | 2 ATP [23] | Low energy cost; high driving force. | Oxygen sensitivity; limited host range. |

| HP/HB Cycle | Archaea (e.g., Metallosphaera) | Moderate ATP cost | Good thermodynamic driving force; suitable for high-productivity systems [23]. | Less common; may require extensive engineering in non-native hosts. |

Metabolic engineering efforts have successfully introduced autotrophic capabilities into industrial heterotrophic hosts. For example, autotrophic strains of E. coli and Pichia pastoris have been generated by implementing synthetic COâ‚‚ fixation pathways and subsequent adaptive laboratory evolution [22]. This expands the range of chassis organisms that can be used for C1 biomanufacturing.

The following diagram illustrates the logical workflow for developing and optimizing a microbial platform for C1 biomanufacturing, integrating computational and experimental approaches.

Engineering Microbial Chassis for Enhanced C1 Utilization

Platform Chassis: Native Autotrophs vs. Engineered Heterotrophs

Two primary strategies exist for developing microbial platforms for C1 utilization: engineering native C1-utilizing organisms and conferring autotrophic capabilities to industrial heterotrophic workhorses.

- Engineering Native Autotrophs: Organisms like cyanobacteria, acetogens, and methanogens are naturally equipped with C1 assimilation pathways. Their engineering focuses on enhancing growth kinetics, product tolerance, and redirecting carbon flux toward non-native products [14]. For instance, the cyanobacterium Synechocystis sp. PCC 6803 has been engineered to produce 1-butanol and lactate from COâ‚‚ [22], and Clostridium autoethanogenum has been engineered to convert syngas to acetone and isopropanol at pilot scale [22].

- Engineering Heterotrophic Chassis: Industrial workhorses like Escherichia coli and Saccharomyces cerevisiae offer advantages such as fast growth, well-established genetic tools, and a proven track record in large-scale fermentation. Creating synthetic autotrophs in these hosts involves the introduction of heterologous C1 fixation pathways (e.g., the Calvin cycle or reductive glycine pathway) and often requires adaptive laboratory evolution to establish robust autotrophic growth [14] [22]. This approach aims to merge the superior C1-fixation capabilities of autotrophs with the industrial robustness and product versatility of heterotrophs.

Enabling Tools for Chassis Engineering

The refinement of microbial chassis relies on a suite of advanced synthetic biology tools.

- CRISPR-Cas Systems: CRISPR-Cas tools have revolutionized the genetic engineering of C1 microbes. They enable efficient gene knockouts, knock-ins, and multiplexed gene regulation (CRISPRi/a) [22]. While initially challenging to implement in non-model C1 organisms like acetogens and methanogens, CRISPR-Cas systems are now being adapted for these hosts, accelerating strain engineering cycles [22].

- Systems Metabolic Engineering: This discipline employs a holistic, systems-level approach to optimize the entire metabolic network of a cell factory. Strategies include:

- AI and Computational Design Tools: The integration of artificial intelligence (AI) and machine learning (ML) is becoming indispensable. AI-driven retrobiosynthesis tools (e.g., RetroPath2.0, AiZynthFinder) can design novel metabolic pathways to target chemicals [24] [20]. Furthermore, Genome-scale Metabolic Models (GEMs) allow for in silico simulation of metabolic fluxes, enabling the prediction of optimal gene knockout and overexpression targets to maximize product yield and productivity before conducting lab experiments [9] [20].

Experimental Protocols for Strain Evaluation and Optimization

Protocol: In Silico Evaluation of Chassis Performance Using GEMs

Purpose: To computationally identify the most suitable microbial chassis and metabolic engineering strategies for producing a target chemical from a C1 feedstock [9].

Procedure:

- Model Selection: Select curated GEMs for candidate chassis organisms (e.g., E. coli, S. cerevisiae, B. subtilis, C. glutamicum, P. putida) [9].

- Constraint Definition: Set constraints to simulate autotrophic growth on the target C1 substrate (e.g., COâ‚‚, methanol). Define the uptake rate for the C1 source and any necessary co-substrates (e.g., Hâ‚‚ for the Wood-Ljungdahl pathway).

- Target Reaction Addition: Add a heterologous reaction or pathway for the synthesis of the target chemical to the model if it is not natively present.

- Flux Balance Analysis (FBA): Perform FBA with the objective of maximizing the biomass growth rate or the secretion rate of the target chemical.

- Yield Calculation: Calculate the maximum theoretical yield (mol product / mol C1 substrate) and the maximum achievable yield under simulated industrial conditions for each chassis [9].

- Intervention Prediction: Use algorithms like OptKnock to identify gene knockout or up/down-regulation strategies that couple product synthesis to growth.

- Comparative Analysis: Rank the chassis organisms based on the calculated yields and the complexity of the required metabolic interventions.

Protocol: Two-Stage Bioprocess for 3-HP Production from COâ‚‚-derived Methanol

Purpose: To experimentally produce 3-hydroxypropionic acid (3-HP), a platform chemical, from COâ‚‚ using an integrated electrochemical-biological (electro-bio-cascade) approach [7].

Procedure:

- Stage 1: Electrochemical Conversion

- Utilize a electrocatalytic reactor to convert captured CO₂ into methanol (CH₃OH). This reaction is typically powered by renewable electricity to ensure a sustainable pathway [7] [21].

- Reaction: CO₂ + 2H₂O + electricity → CH₃OH + 1.5O₂ [21].

- Purify the methanol stream to remove contaminants inhibitory to microbial growth.

- Stage 2: Microbial Conversion

- Strain: Use an engineered methylotrophic bacterium (e.g., Methylobacterium extorquens) or yeast capable of assimilating methanol and producing 3-HP [7].

- Fermentation: Inoculate a bioreactor with the production strain using methanol as the sole carbon source.

- Process Control: Maintain optimal conditions (pH, temperature, dissolved oxygen) and employ fed-batch strategies to control methanol feeding and prevent toxicity.

- Analytics: Monitor cell density (OD₆₀₀), methanol consumption, and 3-HP titer over time using HPLC or GC-MS.

This two-step strategy can overcome the low efficiency of direct one-step COâ‚‚ fixation by microbes, as the initial electrochemical step achieves high conversion rates, and the subsequent fermentation leverages microbial specificity for complex synthesis [21].

The Scientist's Toolkit: Key Research Reagents and Solutions

Table 3: Essential Reagents and Materials for C1 Biomanufacturing Research

| Category / Item | Specific Examples | Function / Application | Key Considerations |

|---|---|---|---|

| Chassis Organisms | Cupriavidus necator H16, Clostridium autoethanogenum, Synechocystis sp. PCC 6803, engineered E. coli [9] [14] [22]. | Native or engineered platform for C1 assimilation and product formation. | Choose based on feedstock (COâ‚‚, CO, CHâ‚„), required culture conditions (aerobic/anaerobic/photo), and genetic tractability. |

| Genetic Engineering Tools | CRISPR-Cas9/Cas12 systems; Plasmid vectors with autotrophic promoters; DNA assembly kits (Gibson Assembly, Golden Gate) [22]. | Enables gene knockout, knock-in, and transcriptional regulation in the chassis. | Optimization of transformation efficiency and CRISPR tools is often required for non-model C1 organisms. |

| Culture Media & Gases | Defined mineral media; C1 substrates: COâ‚‚ gas, CO/Nâ‚‚ mix, CHâ‚„/air mix, methanol, sodium formate [7] [21]. | Provides essential nutrients and the C1 carbon source for growth and production. | For gases, ensure proper bioreactor sparging systems and safety measures for toxic gases (e.g., CO). |

| Bioreactors | Multivariate bioreactor systems; Photo-bioreactors (for cyanobacteria); Gas fermentation reactors [7]. | Provides controlled environment (pH, temp, gas mixing) for optimal strain performance. | Critical for scaling and emulating industrial conditions. Gas-liquid mass transfer is a key design parameter. |

| Analytical Standards | 3-Hydroxypropionic acid, Mevalonic acid, Succinic acid, Isopropanol, Fatty acids, Isotopically labeled CO₂ (¹³CO₂) [9] [7]. | Used as standards for quantifying products and metabolic fluxes via HPLC, GC-MS, LC-MS. | Essential for accurate measurement of Titers, Rates, and Yields (TRY). |

| Bioinformatics Software | Genome-scale metabolic models (GEMs); Retrobiosynthesis platforms (RetroPath2.0); Flux balance analysis tools (COBRApy) [9] [24] [20]. | For in silico pathway design, strain analysis, and prediction of metabolic engineering targets. | Relies on high-quality, curated models for accurate predictions. |

| Cervinomycin A2 | Cervinomycin A2, CAS:113518-96-0, MF:C29H21NO9, MW:527.5 g/mol | Chemical Reagent | Bench Chemicals |

| Pezulepistat | Pezulepistat, CAS:2562303-35-7, MF:C46H61N11O13S, MW:1008.1 g/mol | Chemical Reagent | Bench Chemicals |

Technical and Economic Hurdles

Despite its promise, the path to commercializing C1 biomanufacturing is fraught with challenges.

- Low Carbon Conversion Efficiency: The overall carbon conversion efficiency from C1 feedstock to product often remains below 10%, which is lower than that of conventional fossil-derived routes [7]. This low yield necessitates larger-scale infrastructure to achieve meaningful production volumes, driving up both capital expenditures (CAPEX) and operating expenditures (OPEX) [7].

- Metabolic and Energetic Imbalances: Introducing heterologous C1 pathways can create bioenergetic trade-offs between energy efficiency (yield) and growth rate, potentially compromising the fitness of the engineered strain [23]. Inefficient enzyme kinetics and poor compatibility between the new pathways and the host's native metabolism are common bottlenecks [8].

- Feedstock Cost and Sourcing: The cost of C1 raw materials can constitute over 57% of OPEX [7]. The decentralized nature of waste C1 streams (e.g., from landfills or wastewater plants) complicates the establishment of reliable and cost-effective supply chains comparable to those for crude oil.

Overcoming these barriers requires a concerted effort in systems-level integration, combining multi-omics-guided strain optimization, AI-assisted protein and pathway engineering, and dynamic metabolic regulation to enhance both the efficiency and resilience of these biological systems [8] [7].

C1 feedstocks hold transformative potential for establishing a carbon-negative bioeconomy. The convergence of synthetic biology, systems metabolic engineering, and artificial intelligence is providing the tools necessary to engineer robust microbial cell factories that can efficiently convert COâ‚‚, CO, and CHâ‚„ into a wide array of value-added chemicals and materials.

Future progress hinges on breaking the trade-offs between pathway yield and metabolic driving force, developing more efficient chassis organisms, and integrating C1 bioprocesses with renewable energy to ensure true sustainability [23] [7]. The roadmap to economic viability involves iterative cycles of design, building, testing, and learning, rigorously supported by techno-economic analysis and life cycle assessment to guide research priorities toward commercially scalable and environmentally beneficial processes [7]. As these technologies mature, C1-based biomanufacturing is poised to become a cornerstone of a circular economy, directly contributing to climate change mitigation by transforming waste carbon into valuable products.

Core Principles of Third-Generation (3G) Biomanufacturing

Third-generation (3G) biomanufacturing represents a paradigm shift in industrial biotechnology, moving beyond traditional sugar-based (first-generation) and biomass-based (second-generation) feedstocks to utilize one-carbon (C1) compounds as primary substrates [25]. This innovative approach aims to de-fossilize chemical production and foster a circular carbon economy by recycling waste greenhouse gases, such as carbon dioxide (CO₂), carbon monoxide (CO), and methane (CH₄), into valuable products [7]. The core principle involves leveraging natural or engineered biological systems—including microorganisms and enzymes—to transform these abundant, often waste-derived C1 resources into chemicals, fuels, and materials, thereby providing scalable and sustainable alternatives to traditional petrochemical production [7] [26].

The typical 3G biomanufacturing process involves several integrated stages: feedstock pre-treatment, bioconversion or electro-bio-conversion, product separation, and waste management [7]. This process is often powered by renewable energy sources, such as solar or wind, creating a fully renewable pathway that can achieve a negative carbon footprint [7] [27]. For instance, some demonstrated processes consume 1.17 to 1.78 kg of COâ‚‚ to produce 1 kg of chemical, in stark contrast to traditional petrochemical routes which emit 1.85 to 2.55 kg of COâ‚‚ per kg of product [27].

Key C1 Feedstocks and Microbial Assimilation Pathways

C1 feedstocks are simple, one-carbon molecules that serve as the fundamental carbon source in 3G biomanufacturing. Their abundance, particularly in industrial waste streams, makes them ideal substrates for a circular economy.

- Carbon Dioxide (COâ‚‚): A primary greenhouse gas, COâ‚‚ can be captured from industrial point sources (e.g., steel mills) or directly from the atmosphere [7] [25].

- Carbon Monoxide (CO): Often found in industrial off-gases, such as syngas from steel production [7] [27].

- Methane (CHâ‚„): Sourced from natural gas, agricultural activities, or wastewater treatment plants [7] [25].

- Methanol (CH₃OH): Can be electrochemically produced from CO₂ using renewable energy, serving as a liquid C1 carrier [7].

Native C1 Assimilation Pathways in Microorganisms

Certain native microorganisms, known as C1-trophs, possess specialized metabolic pathways to fix and assimilate C1 compounds. The most efficient natural pathways are central to microbial C1 utilization [25]:

- The Wood-Ljungdahl Pathway (WLP): A primary anaerobic pathway used by acetogenic bacteria (e.g., Clostridium autoethanogenum) to utilize COâ‚‚ and CO. It is highly energy-efficient and serves as a core platform for engineering [25] [27].

- The Ribulose Monophosphate (RuMP) Pathway: Employed by methylotrophic bacteria (e.g., Methylococcus capsulatus) to assimilate methane and methanol. It is known for its high carbon efficiency [25].

- The Xylulose Monophosphate (XuMP) Pathway: Found in methylotrophic yeasts (e.g., Pichia pastoris) for methanol assimilation [25].

- The Calvin Cycle: Used by photosynthetic autotrophs like cyanobacteria to fix COâ‚‚ [25].

The following diagram illustrates the logical flow of feedstock selection and primary metabolic pathways in native C1-trophic microorganisms.

Techno-Economic Challenges and Analysis

Despite its promise, the commercialization of 3G biomanufacturing faces significant techno-economic hurdles. Techno-economic analysis (TEA) is a critical tool for evaluating the economic viability and identifying primary obstacles to industrialization [7].

Table 1: Key Economic Barriers in C1 Biomanufacturing

| Barrier | Impact on Cost | Example from Case Studies |

|---|---|---|

| Low Carbon-to-Product Yield | Increases both Capital Expenditures (CAPEX) and Operating Expenditures (OPEX) by requiring larger-scale infrastructure and more raw materials to compensate for low productivity [7]. | Conversion efficiency for C1 feedstocks to chemicals in bio-cascade and electro-bio-cascade routes remains below 10%, lower than conventional fossil routes [7]. |

| High Cost of Bioreactors | Fermentation-related equipment represents the largest share of capital costs, often exceeding 92% of total equipment costs [7]. | The scale of sterilization infrastructure and bioreactor capacity must expand to meet demand driven by low carbon yield, significantly increasing CAPEX [7]. |

| Variable & Costly Feedstocks | Feedstock cost is the dominant component of OPEX, accounting for over 57% of total operating costs [7]. The decentralized nature of C1 resources introduces supply chain risks and economies of scale challenges not faced by centralized petrochemical refineries [7]. | The availability of stranded methane varies dramatically, from <1 ton/day at wastewater plants to ~31 tons/day at landfills, affecting project viability [7]. |

Quantitative TEA reveals that chemicals derived from C1 feedstocks currently have a higher minimum selling price than their fossil-based alternatives [7]. Overcoming these barriers requires a multi-pronged approach focusing on enhancing carbon conversion efficiency, optimizing bioreactor design, and securing cost-effective and consistent waste gas supplies.

Experimental Workflow for Strain and Process Development

Advancing 3G biomanufacturing from laboratory research to industrial pilot scale requires a systematic, iterative workflow that integrates tools from metabolic engineering, synthetic biology, and bioprocess engineering. The following diagram and protocol outline this comprehensive approach.

Detailed Experimental Protocol: A Case Study in Acetone and Isopropanol Production

This protocol is adapted from the pioneering work that produced acetone and isopropanol (IPA) from steel mill waste gas using engineered Clostridium autoethanogenum at pilot scale [27].

Stage 1: In Silico Pathway Design and Enzyme Mining

- Objective Selection: Define the target chemical (e.g., acetone) and host chassis (e.g., C. autoethanogenum, a native ethanol producer).

- Pathway Reconstruction: Identify heterologous enzymes required to reconstitute the biosynthetic pathway. For acetone, this includes:

- Thiolase (ThlA): Condenses acetyl-CoA to acetoacetyl-CoA.

- CoA-transferase (CtfAB): Converts acetoacetyl-CoA to acetoacetate.

- Acetoacetate decarboxylase (Adc): Decarboxylates acetoacetate to acetone.

- Enzyme Library Creation: Mine genomic databases and literature for a broad set of candidate enzyme variants (e.g., 30 variants from ABE strains) to account for potential differences in activity and compatibility in the non-native host [27].

Stage 2: In Vitro Prototyping and Rapid Optimization (iPROBE)

- Cell-Free Protein Synthesis: Express the candidate enzymes individually or in combinations using a cell-free transcription-translation system.

- Pathway Assembly & Testing: Prototype the complete acetone pathway in vitro by combining cell-free expressed enzymes with necessary cofactors and substrates.

- Bottleneck Identification: Use kinetic modeling and proteomic data to identify rate-limiting steps (e.g., CtfAB was identified as a key bottleneck for acetone production) [27]. This step rapidly narrows down the best-performing enzyme combinations without the complexity of full in vivo engineering.

Stage 3: In Vivo Strain Construction and Metabolic Engineering

- Host Genome Preparation: Knock out competing pathways to minimize byproducts. For IPA production, the native primary-secondary alcohol dehydrogenase (sAdh) gene was deleted to prevent premature reduction of acetone to IPA [27].

- Plasmid Library Transformation: Introduce a combinatorial library of pathway designs (e.g., 247 strains with varying enzyme combinations) into the engineered host.

- High-Throughput Screening: Screen the library for high producers of the target compound. The initial best strain produced ~100 mM of acetone [27].

- Strain Optimization for Co-products: For products like IPA, introduce a library of sAdh enzymes into the best acetone-producing strain to efficiently convert acetone to IPA. Near-full conversion (>97%) has been achieved [27].

Stage 4: Bioprocess Scale-Up and Validation

- Bench-Scale Fermentation (2L CSTR): Transfer the optimized strain to a continuous stirred-tank reactor (CSTR) for gas fermentation. Use a continuous gas feed (e.g., steel mill off-gas) and monitor for steady-state production over several weeks. The demonstrated process achieved ~2.5 g/L/h of acetone and ~3 g/L/h of IPA with >80% gas utilization [27].

- Pilot-Scale Validation (120L Loop Bioreactor): Scale the bioprocess to an industrial pilot plant. Performance parameters (e.g., product selectivity, which reached ~90%) should be validated at this larger scale to assess scalability and identify any spatial heterogeneity issues in the reactor environment [27].

- Life Cycle Assessment (LCA): Conduct a cradle-to-gate LCA to quantify the environmental benefits. The referenced process confirmed a negative carbon footprint, consuming 1.78 kg and 1.17 kg of COâ‚‚ per kg of acetone and IPA produced, respectively [27].

The Scientist's Toolkit: Key Research Reagent Solutions

The development of robust 3G biomanufacturing platforms relies on a suite of specialized reagents, biological tools, and computational methods.

Table 2: Essential Research Reagents and Tools for C1 Biomanufacturing

| Category | Specific Tool/Reagent | Function in Research |

|---|---|---|

| Microbial Chassis | Clostridium autoethanogenum | Native acetogen; engineered platform for producing acids, alcohols, and acetone from CO/COâ‚‚ [27]. |

| Methylotrophic bacteria (e.g., Methylococcus) | Utilize methane/methanol via the RuMP pathway for production of single-cell proteins (SCP) and lipids [25]. | |

| Cyanobacteria (e.g., Synechococcus spp.) | Photoautotrophic chassis that fixes COâ‚‚ via the Calvin cycle for producing sugars and bioplastics [25]. | |

| Enzyme Toolkits | Thiolase (ThlA), CoA-transferase (CtfAB), Decarboxylase (Adc) | Heterologous enzymes reconstituted to create novel product pathways in non-native hosts [27]. |

| Formaldehyde dehydrogenases, Transketolases | Key enzymes in the RuMP and XuMP pathways for formaldehyde assimilation and carbon rearrangement [25]. | |

| Engineering Tools | Adaptive Laboratory Evolution (ALE) | Method for improving host fitness, substrate utilization, and tolerance under C1 conditions [25]. |

| Multi-omics Analysis (Proteomics, Metabolomics) | Guides strain optimization by identifying metabolic bottlenecks and imbalances [8] [27]. | |

| AI & Machine Learning | Assists in protein engineering, pathway prediction, and optimization of metabolic fluxes [8]. | |

| Cell-Free Systems | In vitro Prototyping (iPROBE) | Enables rapid, multiplexed testing of enzyme variants and pathway designs without constraints of cellular metabolism [27]. |

| Process Materials | Continuous Stirred-Tank Reactor (CSTR) | Standard bench-scale bioreactor for continuous gas fermentation process development [27]. |

| Loop Bioreactor | Industrial-scale reactor design for efficient gas-liquid mass transfer, critical for pilot-scale production [27]. | |

| CK-2-68 | CK-2-68, MF:C24H17ClF3NO2, MW:443.8 g/mol | Chemical Reagent |

| Aibellin | Aibellin, MF:C94H148N22O26, MW:2002.3 g/mol | Chemical Reagent |

Third-generation biomanufacturing presents a transformative framework for sustainable chemical production by integrating C1 waste gases into a circular bioeconomy. While significant challenges in carbon conversion efficiency and process economics remain, the convergence of synthetic biology, systems-level metabolic engineering, and AI-assisted design is rapidly advancing the field [8]. The iterative application of TEA and LCA provides an essential feedback loop to guide research towards economically viable and environmentally beneficial outcomes [7]. As demonstrated by successful pilot-scale production of compounds like acetone and single-cell proteins, the continued development of robust microbial chassis and efficient bioreactor systems will be crucial for achieving full industrialization, ultimately displacing fossil resource dependence and contributing to global carbon neutrality goals.

Building Better Biofactories: Methodologies for Chassis Design and Engineering

The transition to a sustainable, bio-based economy necessitates the development of advanced microbial cell factories capable of efficiently converting renewable resources into valuable chemicals. Within this framework, microbial chassis are engineered hosts optimized for industrial-scale bioproduction, moving beyond traditional model organisms to encompass non-conventional hosts with specialized metabolic capabilities [4] [28]. The performance of these chassis hinges on three cornerstone engineering strategies: precursor engineering to optimize flux through key metabolic nodes, tolerance engineering to enable resilience against industrial stressors and toxic compounds, and cofactor engineering to balance the redox and energy requirements of heterologous pathways. These approaches are not mutually exclusive; rather, they function synergistically to unlock the full potential of microbial systems for the sustainable manufacturing of chemicals, fuels, and materials, ultimately supporting the development of a circular carbon economy [28] [29].

Precursor Engineering: Directing Carbon Flux for Biosynthesis

Precursor engineering focuses on manipulating central carbon metabolism to enhance the supply of foundational metabolic building blocks. This involves amplifying native precursor pools, introducing heterologous pathways, and dynamically regulating carbon flux to overcome metabolic bottlenecks and maximize product yields.

Strategic Approaches and Key Metabolic Nodes

The strategic redirection of carbon flux toward desired precursors involves multiple complementary approaches. Amplification of native precursor pools is achieved through the overexpression of bottleneck enzymes in endogenous pathways, such as those in the TCA cycle or glycolysis. Implementation of synthetic pathways introduces non-native routes to bypass naturally inefficient or regulated steps, as exemplified by the heterologous mevalonate (MVA) pathway for terpenoid synthesis in E. coli [30]. Dynamic flux control utilizes biosensors and regulatory circuits to autonomously balance growth and production phases, preventing premature metabolic diversion [31]. Key precursor metabolites frequently targeted in engineering efforts include acetyl-CoA, the central building block for fatty acids, polyhydroxyalkanoates (PHAs), and terpenoids; propionyl-CoA, essential for the synthesis of odd-chain monomers in copolymers like PHBV; and the terpenoid precursors IPP and DMAPP [10] [30].

Case Study: Precursor Engineering for PHBV Biosynthesis

The production of poly(3-hydroxybutyrate-co-3-hydroxyvalerate) (PHBV), a biodegradable bioplastic, critically depends on the coordinated supply of two precursors: acetyl-CoA and propionyl-CoA. The 3-hydroxyvalerate (3HV) monomer is derived from propionyl-CoA, which is often a limiting precursor. Table 1 summarizes major precursor engineering strategies applied in different microbial chassis for enhancing PHBV production [10].

Table 1: Precursor Engineering Strategies for PHBV Production in Microbial Chassis

| Microbial Chassis | Precursor Engineering Strategy | Key Enzymes/Pathways Targeted | Outcome |

|---|---|---|---|

| E. coli | Heterologous pathway expression | Succinyl-CoA→propionyl-CoA pathway (prpE, scpC) | Enhanced 3HV fraction from unrelated carbon sources |

| Ralstonia eutropha | Carbon source co-feeding | Supplementation with propionate/valerate | High PHBV titer and 3HV content |

| Halophiles (e.g., Halomonas) | Native pathway reinforcement | threonine→succinyl-CoA→propionyl-CoA pathway | Promoted synthesis from cheap carbon sources |

| Corynebacterium glutamicum | Anaplerotic node engineering | Pyruvate carboxylase, phosphoenolpyruvate carboxylase | Improved acetyl-CoA and propionyl-CoA supply |

The following diagram illustrates the integrated metabolic engineering strategies in R. eutropha for directing carbon flux towards the PHBV precursors, acetyl-CoA and propionyl-CoA.

Figure 1: Metabolic network for PHBV biosynthesis in engineered R. eutropha. Key engineering targets (phaA, phaB) for enhancing precursor condensation are highlighted.