Metabolic Engineering Conferences 2025: A Comprehensive Guide for Researchers and Drug Development Professionals

This article provides a detailed overview of the 2025 metabolic engineering conference landscape, offering researchers and drug development professionals strategic insights into premier events worldwide.

Metabolic Engineering Conferences 2025: A Comprehensive Guide for Researchers and Drug Development Professionals

Abstract

This article provides a detailed overview of the 2025 metabolic engineering conference landscape, offering researchers and drug development professionals strategic insights into premier events worldwide. It covers foundational conference information, methodological advancements in tools like CRISPR/Cas9 and AI-driven optimization, troubleshooting strategies for production challenges, and validation approaches for translating research into clinical and industrial applications. The guide serves as an essential resource for maximizing conference participation and staying current with cutting-edge developments in metabolic engineering for biomedical applications.

Navigating the 2025 Metabolic Engineering Conference Landscape: Key Events and Opportunities

Metabolic Engineering 16 (ME16) is the premier global conference in the field, organized by the International Metabolic Engineering Society (IMES). This conference serves as a unique platform for researchers, scientists, and industry professionals to learn about the latest methodologies and applications, connect with leading experts from both academia and industry, and forge new collaborations [1]. The meeting will be held from June 15 to June 19, 2025, at the Tivoli Hotel and Congress Center in the heart of Copenhagen, Denmark [2] [3]. The conference is structured as a single-track event with short talks, encouraging extensive networking and discussion among the 500-600 anticipated participants [1].

Detailed Conference Specifications

Dates and Location

The ME16 conference will run from Sunday, June 15, 2025, to Thursday, June 19, 2025. The venue is the Tivoli Hotel and Congress Center, located in the center of Copenhagen, Denmark's capital city [2] [1]. Registration and badge pick-up will begin at 13:30 on Sunday, June 15, with opening remarks scheduled for 15:10 [4].

Conference Scope and Technical Themes

ME16 will focus on the most recent advances in metabolic engineering, pushing the frontiers by developing new tools and methodologies while expanding application areas [3]. The technical program encompasses a broad range of cutting-edge topics essential for researchers and drug development professionals:

Metabolic Engineering for Biofuels and Biochemicals: Sessions will cover the conversion of methanol and CO2 to C4 chemicals, microbial oleochemical synthesis, and co-utilization of multiple sugars for producing cellulosic biofuels [4]. Recent comprehensive reviews highlight advancements in synthetic biology and metabolic engineering for sustainable next-generation biofuels, including the application of CRISPR-Cas systems for precise genome editing and de novo pathway engineering for advanced biofuels such as butanol, isoprenoids, and jet fuel analogs [5].

Metabolic Engineering for Health: This segment includes engineering microbes for dynamic host-microbiome modulation, elucidation of final steps of Taxol biosynthesis for biotechnological production, tools for engineering microbes and microbiota, and multiplex genome editing to eliminate lactate production in mammalian cells without impacting growth rate [4].

Metabolic Engineering for Food and Feed Ingredients and Agriculture: Topics include generating superior industrial yeasts for industrial fermentations, spatial engineering for terpenoid overproduction, harnessing fungi for food and sustainability, and computational design of regulation in interacting soil bacilli [4].

Metabolic Engineering for Gas Fermentation: Sessions will explore essential tools to improve gas-fermenting microorganisms, thermophilic methanogens in biotechnology for CO2 conversion beyond biomethanation, electro-biodiesel empowered by synthetic biology design, and coupling growth of E. coli to synthetic CO2 fixation cycles [4].

Metabolic Engineering for Plastic Recycling: This includes open-loop recycling using engineered microbes, synthetic biology of halophilic bacteria for next-generation industrial biotechnology, engineering bacteria to consume nylon degradation products, and developing E. coli bioprocesses for polyethylene terephthalate degradation [4].

Emerging Tools and Strategies: The conference will highlight data-driven chassis engineering for efficient biosynthesis, controlling life with small molecules, and other novel approaches shaping the future of metabolic engineering [4].

Quantitative Data Analysis

| Registration Category | IMES Member Early Bird | Non-Member Early Bird | IMES Member Standard | Non-Member Standard |

|---|---|---|---|---|

| Industry Professional with Hotel | $3,005 | $3,205 | $3,105 | $3,305 |

| Academic with Hotel | $2,805 | $3,005 | $2,905 | $3,105 |

| Student with Hotel | $1,485 | $1,585 | SOLD OUT | SOLD OUT |

| Industry Professional, No Hotel | $2,305 | $2,505 | ||

| Academic, No Hotel | $2,105 | $2,305 | ||

| Student, No Hotel | $1,085 | $1,185 |

Early Bird pricing ends May 5, 2025. Hotel room availability cannot be guaranteed after this deadline.

| Day | Time (CEST) | Session | Key Topics |

|---|---|---|---|

| Sun, Jun 15 | 17:00-18:00 | Metabolic Engineering for Biofuels and Biochemicals | CO2 to C4 chemicals, microbial oleochemical synthesis, sugar co-utilization |

| Mon, Jun 16 | 8:30-9:30 | Metabolic Engineering for Health | Host-microbiome modulation, Taxol biosynthesis, microbiome engineering tools |

| Mon, Jun 16 | 14:30-15:30 | Metabolic Engineering for Gas Fermentation | Omics and chemostats, thermophilic methanogens, electro-biodiesel, CO2 fixation |

| Tue, Jun 17 | 9:05-10:05 | Emerging Tools and Strategies | Data-driven chassis engineering, controlling life with small molecules |

Experimental Methodologies in Metabolic Engineering

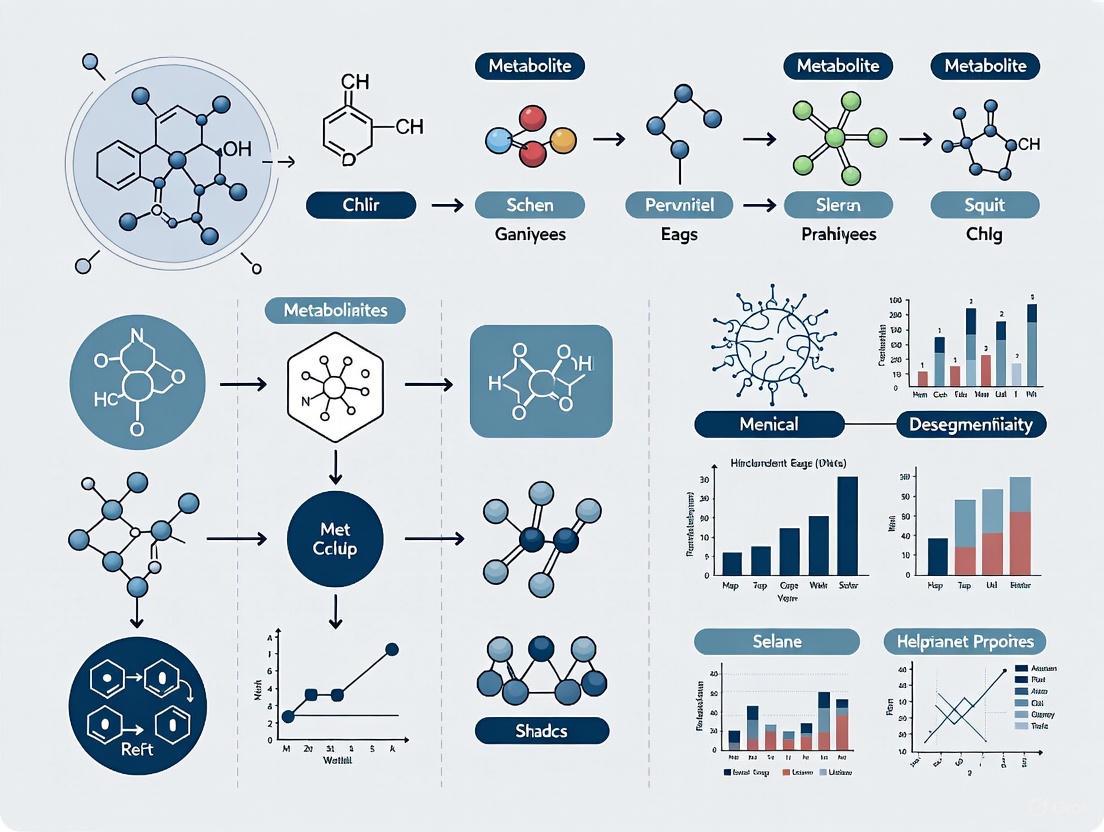

Core Workflow for Microbial Strain Development

The following diagram illustrates the standard experimental workflow for developing high-yield microbial strains, a fundamental methodology in metabolic engineering discussed at ME16.

Research Reagent Solutions for Metabolic Engineering

Table: Essential Research Tools and Reagents for Metabolic Engineering Protocols

| Reagent/Tool | Function | Application Example |

|---|---|---|

| CRISPR-Cas Systems | Precise genome editing using RNA-guided nucleases | Gene knockouts, promoter engineering, multiplexed editing [5] [6] |

| Multiplex Automated Genome Engineering (MAGE) | Automated, multiplexed genome editing across multiple chromosomal locations | Simultaneous optimization of multiple genes in a pathway [6] |

| Genome-Scale Metabolic Models (GEMs) | Computational models predicting metabolic fluxes | Identifying gene knockout targets, predicting substrate utilization [7] |

| Cellulosomal Enzymes | Enzyme complexes for lignocellulosic biomass degradation | Hydrolysis of cellulose and hemicellulose to fermentable sugars [6] |

| Orthogonal Redox Cofactors | Non-interfering redox cofactors for reaction control | Precise tuning of metabolic pathways independently of cellular redox homeostasis [8] |

| RNA Scaffolds | Programmable RNA for spatial organization of enzymes | Dynamic CRISPR transcriptional regulation of metabolic pathways [4] [8] |

Metabolic Pathway Engineering for Biofuel Production

Advanced biofuel production requires systematic engineering of microbial metabolism, as demonstrated in recent studies that will be featured at ME16.

Keynote and Plenary Sessions

ME16 will feature distinguished plenary speakers and keynote presentations addressing the most pressing challenges and opportunities in metabolic engineering:

Nelson Barton (Executive Vice President and Chief Technology Officer at Geno) will deliver a keynote on leveraging AI and machine learning to shorten development timelines and reduce costs in biomanufacturing, highlighting Geno's "model, predict, engineer, scale" approach [7].

Christopher Voigt (Massachusetts Institute of Technology) will present on "Genetic Circuit Design for Agriculture" in the opening keynote session [4].

Mads Krogsgaard Thomsen (Novo Nordisk Foundation) will deliver a keynote titled "GLP-1: From the Academic Discovery to the World's Best-Selling Drug Class," highlighting the translation of basic research into therapeutic applications [4].

Sang Yup Lee (KAIST) will present the Greg Stephanopoulos Award Lecture on "Metabolic Engineering of Bacteria for the Production of Aromatic Chemicals and Polymers" [4].

The conference will also feature numerous invited speakers from leading academic and industrial institutions worldwide, including Shota Atsumi, Lars Blank, Matthew Chang, George Guo-Qiang Chen, Vassily Hatzimanikatis, Vayu Hill-Maini, Sang Yup Lee, Nathan Lewis, and Brian Pfleger, among others [1].

ME16 in Copenhagen represents the pinnacle of metabolic engineering conferences for 2025, offering an unparalleled opportunity for researchers, scientists, and drug development professionals to engage with cutting-edge research, methodologies, and applications across the entire spectrum of metabolic engineering. The conference's comprehensive technical program, spanning biofuels, therapeutic development, sustainable food production, gas fermentation, and plastic recycling, reflects the field's expanding scope and societal impact. With its single-track format, emphasis on networking, and presentation of groundbreaking research, ME16 provides an essential forum for advancing both the science and collaborative relationships that drive innovation in metabolic engineering. The methodologies, tools, and experimental approaches featured at the conference will undoubtedly shape the future trajectory of bio-based production and sustainable biomanufacturing.

The field of plant metabolic engineering is undergoing a revolutionary transformation, driven by converging advances in artificial intelligence, synthetic biology, and high-throughput analytical technologies. This whitepaper examines two premier scientific gatherings that are shaping the future of this discipline: the Plant Metabolic Engineering Gordon Research Conference (GRC) and Phytofactories 2025. These conferences represent critical nexus points where fundamental research meets industrial application, creating collaborative frameworks that accelerate innovation in sustainable biomanufacturing, therapeutic discovery, and climate-resilient agriculture. Within the broader context of metabolic engineering conferences in 2025, these specialized meetings offer distinct yet complementary perspectives on harnessing plant systems for human and planetary health [9] [10].

The 2025 conference season reflects a pivotal moment for plant sciences, characterized by several converging trends. First, the integration of computational approaches, particularly artificial intelligence and machine learning, is transitioning from exploratory to central roles in pathway prediction and optimization. Second, there is growing emphasis on translating basic research into scalable industrial processes and commercial products. Third, the field is increasingly adopting cross-disciplinary approaches that connect fundamental plant biology with engineering principles, clinical research, and environmental sustainability. These gatherings serve as primary venues where these interdisciplinary connections are forged and strengthened, ultimately driving the entire field toward more predictive and systematic engineering of plant metabolic systems [9] [11] [12].

Comparative Analysis of Conference Features

The Plant Metabolic Engineering GRC and Phytofactories 2025, while both operating in the same broad technological domain, serve distinct roles within the research ecosystem. Their complementary nature offers strategic opportunities for researchers with different specializations and career objectives.

Table 1: Strategic Comparison of Premier 2025 Plant Metabolic Engineering Conferences

| Feature | Plant Metabolic Engineering GRC | Phytofactories 2025 |

|---|---|---|

| Primary Focus | Fundamental mechanisms & cross-cutting technologies [9] | Applied processes & industrial translation [10] |

| Date & Location | June 15-20, 2025 (remote location) [9] | June 18-20, 2025 (Luxembourg) [10] |

| Core Themes | AI integration, climate resilience, plant-microbe interactions, drug discovery [9] | Plant cell/tissue culture, bioprocessing, molecular farming, genome editing [10] |

| Presentation Emphasis | Unpublished, cutting-edge research with extended discussion [9] | Production optimization, metabolite characterization, pilot processes [10] |

| Associated Early-Career Event | Plant Metabolic Engineering GRS (June 14-15) [13] | Not specified in search results |

| Unique Value | Intensive networking in remote setting, interdisciplinary synthesis [9] | Focus on commercialization & International Association for Plant Cell Culture Research [10] |

Positioning Within the 2025 Conference Landscape

Within the broader spectrum of 2025 metabolic engineering conferences, these two gatherings occupy specialized niches. The GRC series represents the gold standard for foundational science and forward-looking research, with its trademark format of unpublished data presentation and immersive discussion. In contrast, Phytofactories 2025 focuses specifically on the translation pathway from laboratory discovery to industrial implementation, particularly through plant molecular farming approaches. Other relevant 2025 meetings include Metabolic Engineering 16 (general microbial and metabolic engineering) and the Institute of Biological Engineering Annual Conference (broad biological engineering applications), but the specialized focus of the GRC and Phytofactories makes them uniquely valuable for researchers working specifically with plant systems [1] [14].

The strategic specialization of these conferences reflects maturation of the plant metabolic engineering field. As fundamental knowledge advances, distinctive sub-communities emerge with their own technical challenges, vocabulary, and application priorities. The GRC serves researchers working on fundamental mechanisms that cut across multiple application areas, while Phytofactories creates a dedicated forum for the plant molecular farming community to address scale-up and manufacturing challenges. For comprehensive coverage of the field, researchers would benefit from attending both conferences or strategically selecting based on their current research phase – fundamental discovery versus process development and commercialization [9] [10].

Technical Program Analysis: Core Methodologies and Research Directions

Advanced Analytical and Computational Methodologies

The 2025 conference programs reveal several advanced methodologies that are becoming standard in cutting-edge plant metabolic engineering research. These techniques enable unprecedented resolution and predictive capability in understanding and manipulating plant metabolic systems.

Table 2: Essential Research Reagent Solutions and Analytical Platforms for Plant Metabolic Engineering

| Technology/Reagent Category | Specific Examples | Primary Research Applications |

|---|---|---|

| High-Resolution Mass Spectrometry | LC-MS, GC-MS systems [11] | Targeted and non-targeted metabolomics, pathway elucidation [11] |

| Stable Isotope Labeling | ¹³C, ¹âµN labeled precursors [11] | Metabolic flux analysis, pathway tracing [11] |

| Plant Cell/Tissue Culture Systems | Callus cultures, hairy root cultures [10] | Metabolic production without whole plants, pathway studies [10] |

| Genome Editing Tools | CRISPR/Cas systems, T-DNA vectors [10] | Targeted gene knockout, pathway engineering, regulatory element modification [10] |

| AI/Language Models | BiomedLM, custom-trained LLMs [12] | Literature mining, database expansion, enzyme-function prediction [12] |

| Single-Cell Analysis Platforms | scRNA-seq, spatially resolved metabolomics [15] | Cell-type specific metabolic specialization, developmental trajectories [15] |

A particularly noteworthy methodological advance presented in the 2025 research landscape is the application of large language models (LLMs) to overcome critical bottlenecks in plant metabolic research. A 2025 study by Knapp et al. demonstrates specialized pipelines using LLMs for structured data extraction from the extensive but fragmented plant metabolism literature. Their approach combines prompt engineering techniques with retrieval-augmented generation to identify validated enzyme-product pairs and compound-species associations with 80-90% accuracy for some tasks. This methodology addresses the fundamental challenge of dispersed knowledge in plant specialized metabolism, where information about biosynthetic pathways, enzyme functions, and metabolite occurrences is distributed across millions of research articles without standardized database representation [12].

Experimental Workflow for AI-Enhanced Metabolic Pathway Discovery

The integration of artificial intelligence with experimental validation represents a paradigm shift in how researchers approach plant metabolic engineering. The following workflow visualization illustrates the iterative cycle between computational prediction and experimental validation that is becoming standard in the field.

Diagram 1: AI-enhanced pathway discovery workflow

This experimental workflow begins with comprehensive data aggregation from diverse sources, including published literature, genomic databases, and experimental datasets. LLMs with specialized training in biological domains perform relationship extraction to identify potential enzyme-substrate-product associations, metabolic compartmentalization patterns, and regulatory interactions. These extracted relationships populate structured knowledge bases that enable pathway prediction algorithms to generate testable hypotheses about complete biosynthetic pathways for high-value plant natural products [12].

The computational predictions then inform precise metabolic engineering interventions, including:

- Enzyme Engineering: Using protein structure prediction and machine learning-guided directed evolution to optimize catalytic efficiency, substrate specificity, or expression characteristics of identified enzymes [9].

- Pathway Assembly: Combinatorial construction of candidate pathways in heterologous systems such as plant cell cultures, yeast, or tobacco hosts [10].

- System Optimization: Fine-tuning regulatory elements, subcellular targeting signals, and scaffolding structures to maximize metabolic flux through engineered pathways [9].

Validation employs advanced analytical techniques, particularly high-resolution mass spectrometry, to confirm metabolite production and quantify titers. Critically, the validation data feeds back into the knowledge base, creating a virtuous cycle of model improvement and prediction refinement. This iterative approach dramatically accelerates the historically slow process of plant pathway elucidation, which traditionally required decades of biochemical characterization for complex natural products [12].

Emerging Technologies and Research Applications

Single-Cell Approaches in Plant Metabolic Engineering

A significant technological frontier highlighted across 2025 conferences is the application of single-cell analyses to plant metabolic engineering. The Single-Cell Approaches in Plant Biology GRC (August 10-15, 2025) specifically focuses on technologies that resolve metabolic heterogeneity at cellular and subcellular levels, moving beyond bulk tissue analyses that mask important functional specializations [15].

These approaches include single-cell RNA sequencing, spatially resolved metabolomics and proteomics, and advanced imaging techniques that collectively enable:

- Cell-Type Specific Metabolic Specialization: Identification of distinct metabolic functions in different cell types within complex plant tissues, revealing which cells produce valuable specialized metabolites [15].

- Metabolic Trajectory Analysis: Mapping metabolic changes during cell differentiation and development, identifying key transition points for engineering interventions [15].

- Subcellular Metabolic Compartmentalization: Understanding how metabolic pathways are organized within different organelles and how metabolite transport occurs between compartments [15].

The following diagram illustrates how single-cell technologies are being integrated with metabolic engineering to create a more precise engineering framework:

Diagram 2: Single-cell informed precision metabolic engineering

This emerging paradigm leverages single-cell data to create computational models that predict how metabolic engineering interventions will affect specific cell types, enabling more precise strategies that maximize product accumulation while minimizing fitness costs to the plant. For example, engineering approaches might specifically target metabolite production to root epidermal cells that naturally specialize in secondary metabolism, rather than constitutively expressing pathways across all cell types [15].

Plant Molecular Farming and Industrial Applications

Phytofactories 2025 emphasizes the growing industrial translation of plant metabolic engineering, particularly through plant molecular farming – using plant cells, tissues, or whole plants as production platforms for high-value compounds. The conference highlights several key application areas that are nearing commercial maturity [10]:

- Therapeutic Proteins and Peptides: Production of vaccines, antibodies, and therapeutic enzymes in plant systems offers advantages in scalability, safety, and cost compared to mammalian cell culture systems.

- Specialized Nutraceuticals and Cosmeceuticals: Engineering plant systems to produce high-value compounds for nutrition and personal care markets, including antioxidants, pigments, and bioactive lipids.

- Plant-Based Natural Products for Drug Discovery: Accessing difficult-to-synthesize plant-derived compounds with pharmaceutical potential through engineered production systems rather than extraction from low-yield native plants.

The industrial focus of Phytofactories is complemented by sessions at the Plant Metabolic Engineering GRC on industrial applications, highlighting how fundamental advances are transitioning to commercial implementation. The GRC program includes case studies on scaling plant metabolic engineering processes, technoeconomic analysis of production platforms, and regulatory considerations for commercial deployment [9] [10].

Quantitative Market Analysis and Growth Projections

The research directions highlighted at these 2025 conferences are supported by strong market growth and increasing investment in plant metabolomics and metabolic engineering technologies. Quantitative analysis of the field reveals significant expansion and economic opportunity.

Table 3: Plant Metabolomics Market Analysis and Growth Projections (2024-2029)

| Market Segment | 2024 Market Size | Projected 2029 Market Size | CAGR | Primary Growth Drivers |

|---|---|---|---|---|

| Total Plant Metabolomics Market | $2.0 billion [11] | $3.5 billion [11] | 10% [11] | AI integration, demand for natural products, agricultural sustainability [11] |

| Targeted Metabolomics | $1.2 billion (60% share) [11] | Not specified | Not specified | Cost-effectiveness, targeted research questions [11] |

| Non-Targeted Metabolomics | $800 million (40% share) [11] | Not specified | Not specified | Novel metabolite discovery, pathway elucidation [11] |

| Medicinal Plant Research | $400 million [11] | Not specified | Not specified | Drug discovery, natural product characterization [11] |

The market data underscores the economic significance of the research directions featured at both conferences. The substantial investment in plant metabolomics technologies (projected 10% CAGR) reflects growing recognition of plants as engineered production systems for diverse compounds. The market analysis also reveals interesting segmentation, with targeted metabolomics holding majority market share due to its cost-effectiveness for specific applications, while non-targeted approaches continue to grow as discovery tools [11].

Geographically, North America and Europe currently dominate the plant metabolomics market, accounting for over 65% of revenue, but Asia-Pacific is projected to show significant growth due to expanding agricultural and pharmaceutical research capabilities in developing economies. This global distribution is reflected in the international participant base of both the GRC and Phytofactories conferences, which draw leading researchers from academic, government, and industry settings worldwide [9] [10] [11].

The 2025 plant metabolic engineering conference season reveals several strategic research directions that are likely to define the field for the coming decade. First, the integration of artificial intelligence and machine learning throughout the research pipeline – from literature mining to pathway prediction and optimization – represents a fundamental shift in methodology. Second, single-cell and spatial technologies are creating new opportunities for precision metabolic engineering that accounts for cellular heterogeneity and specialized microenvironments within plant tissues. Third, there is growing emphasis on translating fundamental discoveries into scalable processes through plant molecular farming approaches [9] [10] [12].

For researchers and drug development professionals, these conferences offer critical venues for tracking the accelerating pace of innovation in plant metabolic engineering. The complementary focuses of the GRC (fundamental mechanisms) and Phytofactories (industrial translation) provide comprehensive coverage of the entire innovation pipeline, from basic discovery to commercial application. As the field continues to mature, the interdisciplinary connections forged at these gatherings – between plant biologists, chemical engineers, computational scientists, and commercial developers – will be essential for realizing the full potential of plant metabolic engineering to address challenges in health, sustainability, and climate resilience [9] [10].

The strong market growth and increasing investment in plant metabolomics technologies suggest that these research directions will continue to attract resources and talent. For drug development professionals specifically, the advances in engineering plant-derived therapeutics and accessing difficult-to-synthesize natural products through heterologous production systems offer new avenues for drug discovery and development. The 2025 conference programs demonstrate that plant metabolic engineering has transitioned from a niche specialty to a central discipline within the broader metabolic engineering landscape, with distinctive methodologies, applications, and commercial opportunities [11].

For researchers, scientists, and drug development professionals, attending the right conference is a strategic decision that can shape research directions and foster pivotal industry collaborations. The 2025 conference calendar features several key events designed to bridge foundational science with industrial application. Two such events—the Euro-Global Conference on Biotechnology and Bioengineering (ECBB) and the Institute of Biological Engineering Annual Conference (IBE)—stand out for their distinct yet complementary focuses on translating biological engineering innovations into real-world solutions. Framed within a broader analysis of metabolic engineering conferences in 2025, this guide provides an in-depth technical comparison of these industry-focused forums. We dissect their technical sessions, showcase groundbreaking research protocols, and provide a toolkit for navigating the conference landscape to maximize professional return in the field of applied metabolic engineering.

The following table summarizes the core details for the two primary industry-focused conferences and includes a premier, more specialized event for contextual comparison.

Table 1: Overview of Key 2025 Conferences in Biotechnology and Bioengineering

| Conference Name | Date(s) | Location | Theme / Focus | Submission Deadline |

|---|---|---|---|---|

| IBE Annual Conference [14] [16] | September 12-13, 2025 [14] | Salt Lake City, Utah, USA [14] | "Innovation through Biological Engineering" [14] | June 15, 2025 [14] |

| Euro-Global (ECBB) [17] [18] | September 18-20, 2025 (5th Ed.) [17] [19]; September 28-30, 2025 (6th Ed.) [18] | London, UK [17] [18] | "Bridging Science and Industry" [19] | Not Specified in Results |

| Metabolic Engineering 16 (Reference) [1] | To be held in Copenhagen, Denmark [1] | Premier, single-track format for foundational science [1] | Not Specified in Results |

The Institute of Biological Engineering (IBE) Annual Conference is a central event for professionals aiming to integrate engineering principles with biological systems. Celebrating its 30th anniversary in 2025, its theme, "Innovation through Biological Engineering," highlights groundbreaking advancements and interdisciplinary approaches across the entire field [14] [16]. In contrast, the Euro-Global Conference on Biotechnology and Bioengineering (ECBB), organized by Magnus Group, offers a global platform with multiple editions in London. Its explicit theme, “Biotechnology and Bioengineering: Bridging Science and Industry,†positions it as a direct channel for engaging with industry pioneers and exploring commercial applications [17] [19]. For reference, Metabolic Engineering 16 is noted as a premier academic conference in the field, providing a foundational science counterpart to the more application-oriented themes of the IBE and ECBB events [1].

Technical Scope: A Comparative Analysis of Sessions and Research Areas

A conference's value is determined by the relevance and depth of its technical content. The following table compares the primary research areas covered at the IBE and ECBB conferences, with a particular focus on topics critical to drug development and industrial biomanufacturing.

Table 2: Comparison of Technical Sessions and Research Areas

| Research Area | IBE Annual Conference Sessions [14] | Euro-Global (ECBB) Sessions [17] |

|---|---|---|

| Biotherapeutics & Medicine | Tissue & Cellular Engineering; Biological Engineering for Health and Safety; Biosensors, Sensing, and Diagnostics [14] | Biomedical Technologies; Cancer Immunotherapy [17] [18] |

| Synthetic Biology & Metabolic Engineering | Synthetic Biology and Metabolic Engineering [14] | Genetic Engineering; Molecular Biology [17] |

| Bioprocessing & Manufacturing | Biomanufacturing & Bioprocessing [14] | Bioprocessing [17] |

| Computational & AI Tools | Biological Systems Modeling & the role of AI [14] | Not Explicitly Listed |

| Sustainability & Bioeconomy | From Linear to Circular Bioeconomy Systems; Sustainable, Bio-derived Fuels, Chemicals, and Materials [14] | Sustainable Bio-industries [17] |

| Commercial Translation | Biological Engineering Commercial Applications in Industry [14] | "Bridging Science and Industry" (Conference Theme) [19] |

The IBE Annual Conference offers a comprehensive and detailed breakdown of biological engineering, with twelve distinct technical sessions [14]. Its strength lies in its breadth, covering everything from foundational tools like synthetic biology and AI-driven modeling to specific application areas like biomanufacturing, the circular bioeconomy, and direct commercial translation. The dedicated session on "Biological Engineering Commercial Applications in Industry" is particularly valuable for professionals seeking to understand market-ready technologies [14].

While the search results do not provide a full list of technical sessions for the ECBB, its stated scope includes "genetic engineering, bioprocessing, molecular biology, [and] biomedical technologies," with featured keynote addresses focusing on concrete problems in drug development, such as "Solving the challenges of engineering an ultra-long acting insulin" and "Targeting noncanonical epitopes in anti-cancer immunotherapy" [17] [18]. This suggests a strong, clinically-oriented focus within the biomedical sphere.

Featured Experimental Protocols from Cutting-Edge Research

A key benefit of attending technical conferences is gaining insight into groundbreaking methodologies. The following section details a protocol for a novel drug delivery system, which exemplifies the type of innovative engineering presented at these forums.

Protocol: Formulation of Room-Temperature-Stable, Lyophilized Milk-Derived Exosomes

This protocol, based on research featured in the Journal of Biological Engineering (the official journal of IBE) and presented at the 2025 IBE conference, describes a lyophilization technique to stabilize exosomes for drug delivery and wound healing applications, overcoming the major clinical bottleneck of cold-chain storage [20] [21].

1. Primary Reagent and Material Preparation:

- Source Material: Fresh or frozen bovine or human milk.

- Exosome Isolation Kit: Commercial kit based on size-exclusion chromatography or precipitation.

- Lyoprotectant Solution: Prepare a 10% (w/v) solution of trehalose in purified water. Trehalose is a non-reducing disaccharide that protects biomembranes and proteins during dehydration.

- Stabilizer Solution: Prepare a 5 mM solution of the amino acid tryptophan in purified water. Tryptophan aids in preventing molecular aggregation.

- Phosphate-Buffered Saline (PBS), pH 7.4.

- Equipment: Ultracentrifuge, lyophilizer (freeze-dryer), nanoparticle tracking analysis (NTA) system, dynamic light scattering (DLS) instrument, and transmission electron microscope (TEM).

2. Step-by-Step Methodology:

- Step 1: Exosome Isolation and Purification. Centrifuge the milk sample at low speed (e.g., 3,000 × g) to remove cells and debris. Filter the supernatant through a 0.45-μm filter. Use the commercial exosome isolation kit according to the manufacturer's instructions to concentrate and purify the exosomes from the filtered supernatant. Resuspend the final exosome pellet in PBS.

- Step 2: Pre-lyophilization Formulation. Combine the purified exosome suspension with the trehalose and tryptophan solutions in a ratio of 5:3:2 (exosome suspension: 10% trehalose: 5 mM tryptophan). Mix gently but thoroughly by inversion. The final concentration of trehalose should be 3% (w/v), and tryptophan should be 1 mM. This combination is critical for preserving exosome structure and bioactivity.

- Step 3: Lyophilization Cycle. Transfer the formulated exosome solution into lyophilization vials. Load the vials into the pre-cooled lyophilizer. Execute a lyophilization cycle with an initial freezing step at -80°C for 2 hours, followed by primary drying at -40°C under a vacuum of 100 mTorr for 24 hours, and a secondary drying step at 25°C for 4 hours to remove residual moisture.

- Step 4: Storage and Reconstitution. Store the resulting lyophilized powder at ambient temperature (15-25°C) protected from light. To reconstitute, add sterile water for injection or an appropriate buffer to the vial and vortex gently for 30 seconds.

3. Validation and Functional Characterization:

- Structural Integrity: Use TEM to confirm the spherical, cup-shaped morphology of the reconstituted exosomes. DLS should be used to verify that the particle size distribution (typically 30-150 nm) is unchanged after lyophilization.

- Bioactivity Assay: Perform a cell proliferation assay (e.g., using fibroblasts) to confirm the retained bioactivity of the reconstituted exosomes compared to fresh, non-lyophilized controls. This is essential for validating the protocol's success for therapeutic applications like wound healing [20].

The workflow for this protocol is outlined in the diagram below.

Figure 1: Workflow for Room-Temperature-Stable Exosome Formulation

The Scientist's Toolkit: Key Research Reagent Solutions

The successful execution of advanced protocols, such as the exosome lyophilization described above, relies on specific, high-quality reagents. The following table details essential materials and their functions, curated from the technical themes of the 2025 conferences.

Table 3: Key Research Reagent Solutions for Advanced Bioengineering

| Reagent / Material | Function in Research | Example Application |

|---|---|---|

| Trehalose [20] | Lyoprotectant; stabilizes lipid bilayers and proteins during freeze-drying by forming a glassy matrix and replacing water molecules. | Room-temperature stabilization of therapeutic exosomes and other biologic nanoparticles [20]. |

| Tryptophan [20] | Stabilizer; helps prevent aggregation of biomolecules during lyophilization and storage. | Enhancing the long-term stability of protein formulations in lyophilized powders [20]. |

| Engineered Enzyme Assembly Lines [14] | Multi-enzyme complexes engineered for biosynthesis of novel compounds, such as anti-infective agents. | Metabolic engineering of pathways to produce novel antibiotics and other therapeutic small molecules [14]. |

| Non-Canonical Amino Acids | Incorporation into proteins or peptides to alter their properties or create novel epitopes. | Developing novel cancer immunotherapies by targeting noncanonical epitopes for immune recognition [18]. |

| CRISPR-Cas Systems | Enables precise genome editing for metabolic pathway engineering and functional genomics. | Knocking out or knocking in genes in microbial hosts or plant systems to enhance production of valuable compounds [14]. |

| AI-Based Pathway Prediction Tools [14] | Software that uses artificial intelligence to model and predict optimal synthetic biology pathways. | Designing and optimizing metabolic networks in silico for efficient bioproduction of fuels, chemicals, and drugs [14]. |

| LSTc | LSTc, CAS:64003-55-0, MF:C37H62N2O29, MW:998.9 g/mol | Chemical Reagent |

| Withaphysalin E | Withaphysalin E|RUO|13,14-seco Withanolide | Withaphysalin E is a withanolide fromPhysalis minimafor research use only (RUO). Study its potential anti-inflammatory and anticancer mechanisms. Not for human use. |

For the drug development professional or researcher operating in the dynamic field of metabolic engineering, a strategic approach to conference attendance in 2025 is crucial. The IBE Annual Conference offers an unparalleled breadth of technical content, with dedicated sessions on AI modeling, commercial applications, and the entire biomanufacturing pipeline, making it ideal for those seeking a comprehensive overview of biological engineering's translational landscape [14]. The Euro-Global Conference on Biotechnology and Bioengineering (ECBB), with its strong emphasis on bridging science and industry and its focus on clinical challenges like immunotherapy and insulin engineering, provides a targeted forum for biomedical researchers and those engaged in late-stage therapeutic development [17] [18] [19].

When integrated with the foundational science presented at a premier conference like Metabolic Engineering 16 [1], these industry-focused events create a powerful knowledge ecosystem. By aligning your specific research and development goals with the technical focus of each conference—and leveraging the experimental insights and toolkits they provide—you can accelerate the journey from scientific discovery to industrial application and therapeutic breakthrough.

The field of metabolomics continues to evolve as an indispensable component of systems biology, providing unparalleled insight into metabolic homeostasis and dysfunction within biological systems. Unlike the genome or proteome, the metabolome more directly reflects the current physiological status, making it a critical tool for driving innovation across diverse scientific and medical domains [22]. The conference landscape in 2025 reflects this growth, with several key events scheduled. Notably, Metabolic Engineering 16 is scheduled as a premier in-person event in Copenhagen, while the Plant Metabolic Engineering Gordon Research Conference is set for June 15-20, 2025 [1] [9]. Within this context, the 4th International Electronic Conference on Metabolomics (IECM 2025) emerges as a significant virtual alternative, offering a freely accessible, specialized forum for global knowledge exchange from October 13-15, 2025 [23]. This online model eliminates geographical and financial barriers, fostering a uniquely inclusive environment for researchers, scientists, and drug development professionals to engage with the latest advancements in metabolomics science. Organized by the MDPI journal Metabolites, the conference is dedicated to providing a forum for exchanging the latest research results and advanced research methods, squarely framing it within the broader 2025 research agenda on metabolic engineering and its applications [23] [22].

Conference at a Glance: Scope and Logistics

The 4th International Electronic Conference on Metabolomics (IECM 2025) is structured as a fully online event, scheduled for 13–15 October 2025. A key advantage for potential participants is that attendance is completely free of charge, broadening access for the global research community [23]. The conference is organized into six core thematic sessions, designed to cover the most pressing and innovative areas within the field.

Table 1: Key Dates and Session Topics for IECM 2025

| Item Type | Date | Description |

|---|---|---|

| Abstract Deadline | 22 August 2025 | Final date for abstract submission for presentation |

| Registration Deadline | 09 October 2025 | Final date to register for the conference |

| Conference Dates | 13–15 October 2025 | Full duration of the online event |

| Session 1 | Clinical Application of Metabolomics with Special Reference to the Endocrinological Arena | |

| Session 2 | Technological Advances in Metabolomics | |

| Session 3 | Advanced Metabolomics and Data Analysis Approaches | |

| Session 4 | Metabolomics for Precision Nutrition in Humans and Animals | |

| Session 5 | The Applications of Metabolomics in Pharmacology and New Drug Development | |

| Session 6 | Microbial Metabolites with Novel Functions in Diseases and Health |

The conference also features award opportunities, including Best Oral Presentation and Best Poster Awards, with six winners each receiving a certificate and 200 CHF [23]. Furthermore, participants have clear publication pathways, with opportunities to submit proceedings papers free of charge to the Biology and Life Science Forum or full manuscripts to a Special Issue of the journal Metabolites (Impact Factor: 3.4), often with a discount on Article Processing Charges (APCs) [23] [22].

Deep Dive into the Scientific Program and Methodologies

The technical program for IECM 2025 is meticulously crafted to showcase cutting-edge research and foster in-depth discussion. The sessions are rich with presentations detailing sophisticated experimental workflows and analytical techniques.

Featured Sessions and Analytical Techniques

- Session 2: Technological Advances in Metabolomics: This session highlights innovations in analytical instrumentation. A featured presentation by Dr. Lin Huang covers "Metabolomics based on laser desorption/ionization mass spectrometry", a method that allows for spatial resolution of metabolites in tissue samples without extensive extraction procedures [22]. Another invited talk by Dr. Yuping Cai focuses on the "Discovery of unknown metabolites and metabolic reactions by mass spectrometry-resolved stable-isotope tracing metabolomics", a powerful technique for elucidating active metabolic pathways [22].

- Session 3: Advanced Metabolomics and Data Analysis Approaches: This segment is dedicated to the computational challenges and solutions in metabolomics. It includes a talk on "ClearAIF: An R-Based Computational Pipeline for DIA Metabolomic Data Processing and Reporting" by Qingqing Mao, which provides an open-source tool for managing complex Data-Independent Acquisition mass spectrometry data [22]. Another presentation by Erik Huckvale demonstrates how "Machine Learning Predicted Pathway Annotations Greatly Improves Pathway Enrichment Analysis", addressing a critical bottleneck in functional interpretation of metabolomic data [22].

- Session 5: Applications in Pharmacology and New Drug Development: This application-oriented session includes research such as a "NMR-based Metabolomic Investigation Of The Effects Of Alzheimer’s Molecular Stressors On Neuroblastoma Cells" by Alessia Vignoli, illustrating the use of in vitro models and NMR to study disease mechanisms [22]. Another project employs "Water fleas as 'canaries in the coal mine' to monitor pharmaceutical pollution using metabolic perturbations as indices", showcasing the use of non-mammalian models in ecotoxicology [22].

Experimental Workflow for Global Metabolomics

A common theme in many presentations, particularly those from clinical and environmental settings, is the workflow for global untargeted metabolomics. This multi-step process is crucial for generating robust and biologically meaningful data.

This workflow was exemplified in recent research from the Oslo University Hospital group, which used global LC-MS metabolomics and LASSO-regression to identify affected pathways in sepsis patients presenting at the emergency department [24]. Their methodology involved optimizing sample preparation for parallel global metabolomics and lipidomics from single tissue samples and employing advanced computational models to extract clinically relevant signatures from complex datasets [24].

Key Research Reagent Solutions

The execution of metabolomics research relies on a suite of specialized reagents and materials to ensure analytical precision and reproducibility.

Table 2: Essential Research Reagents and Materials for Metabolomics Workflows

| Reagent/Material | Primary Function | Application Example |

|---|---|---|

| Stable Isotope Tracers (e.g., ¹³C-Glucose) | Enables tracking of metabolic flux through pathways | Mass spectrometry-resolved flux analysis [22] |

| Dried Blood Spot (DBS) Cards | Minimally invasive sample collection & stabilization | Integrated metabolomics/lipidomics from DBS [22] |

| LC-MS Grade Solvents (e.g., Methanol, Acetonitrile) | Sample extraction & mobile phase for chromatography | Protein precipitation in serum/plasma preparation [24] |

| Quality Control (QC) Pools | Monitors instrument performance & data reproducibility | Pooled sample analyzed throughout batch sequence [24] |

| Chemical Derivatization Reagents | Enhances detection of low-abundance metabolites | GC-MS analysis of organic acids and sugars [25] |

| Solid-Phase Extraction (SPE) Cartridges | Clean-up and fractionation of complex samples | Targeted analysis of specific metabolite classes [24] |

The Scientist's Toolkit: Core Analytical Platforms

The field of metabolomics leverages a suite of complementary analytical platforms, each with distinct strengths. The choice of platform is a critical decision that shapes experimental design and data outcomes.

- Liquid/Gas Chromatography-Mass Spectrometry (LC-MS/GC-MS): This hyphenated technique is a workhorse in metabolomics, providing high sensitivity and the ability to resolve thousands of features in a single sample. LC-MS is ideal for a wide range of polar and non-polar metabolites, while GC-MS is excellent for volatile compounds or those made volatile by derivatization. The development of scheduled data-dependent acquisition MS provides enhanced identification and sensitivity in clinical lipidomics applications [24].

- Nuclear Magnetic Resonance (NMR) Spectroscopy: NMR offers highly reproducible and quantitative data with minimal sample preparation. It is a powerful tool for structural elucidation of unknown metabolites and is non-destructive. Advances include deriving multiple one-dimensional spectra from a single experiment to maximize information content [22].

- Direct Infusion Mass Spectrometry and LDI-MS: These separation-free techniques enable high-throughput analysis. Direct infusion is valuable for rapid fingerprinting and stable-isotope tracer studies [25], while Laser Desorption/Ionization Mass Spectrometry (LDI-MS) is key for spatial metabolomics, allowing for the mapping of metabolites directly from tissue sections [22].

The 4th International Electronic Conference on Metabolomics (IECM 2025) stands as a pivotal virtual event within the 2025 metabolic engineering and metabolomics conference circuit. It successfully encapsulates the current state of the field, which is increasingly defined by technological sophistication, data-driven discovery, and translational applications. The conference's dedicated sessions on AI/ML, advanced data analysis, and computational modeling highlight a definitive shift towards the integration of bioinformatics and artificial intelligence to extract deeper biological meaning from complex datasets. Furthermore, the strong focus on clinical applications, drug discovery, and precision nutrition underscores the field's commitment to addressing real-world challenges in human health and disease. As a free, online event, IECM 2025 embodies the spirit of open science and collaborative progress, offering researchers and drug development professionals an accessible platform to engage with the forefront of metabolomics research, gain insights into cutting-edge methodologies, and contribute to shaping the future trajectory of this rapidly advancing field.

For researchers, scientists, and drug development professionals in metabolic engineering, strategic planning for major conferences is essential for disseminating groundbreaking research, securing funding, and fostering collaborative partnerships. The 2025 conference landscape presents critical timelines that must be navigated with precision to maximize professional impact and research advancement. This technical guide synthesizes comprehensive data on abstract submissions, registration windows, and funding mechanisms for premier events in the field, with particular focus on Metabolic Engineering 16 (ME16) in Copenhagen—the flagship conference organized by the International Metabolic Engineering Society (IMES) [26]. Proper planning for these conferences enables professionals to showcase cutting-edge methodologies in genome editing tools, biomanufacturing scale-up, and AI-driven metabolic modeling while accessing unique networking opportunities with leading academic and industrial experts. The strategic approach outlined herein ensures researchers can align their experimental timelines with these crucial deadlines, optimizing resource allocation and potential for scientific recognition.

Critical Deadline Analysis for Major 2025 Conferences

Metabolic Engineering 16 (ME16) - Primary Conference Analysis

ME16 represents the premier conference in the metabolic engineering field, offering the most comprehensive platform for presenting unpublished research and connecting with international leaders. The conference spans June 15-19, 2025 at the Tivoli Hotel and Congress Center in Copenhagen, Denmark [2], and features a robust scientific program covering metabolic engineering for biofuels, biochemicals, health applications, food and feed ingredients, gas fermentation, plastic recycling, and computational approaches including modeling and artificial intelligence [26].

Table: ME16 Critical Deadlines and Registration Pricing

| Conference Element | Deadline Date | Key Specifications | Financial Considerations |

|---|---|---|---|

| Oral Abstract Submission | February 11-12, 2025 [27] | 400-word limit, 150-character title maximum [27] | No separate submission fee indicated |

| Poster Abstract Submission | April 1-2, 2025 [27] | Standard poster presentations; late submissions not considered for rapidfire talks [27] | No separate submission fee indicated |

| Funding Application | April 1, 2025 [27] | Complimentary/discounted registrations for students, post-docs, early career faculty [27] | Application closed as of deadline [27] |

| Award Nominations | February 1, 2025 [27] | IMES awards program [27] | Recognition of scientific achievements |

| Early Bird Registration | May 5, 2025 [2] | Best pricing for all registration categories [2] | See detailed pricing table below |

| Standard Registration | Through June 19, 2025 [2] | Hotel availability not guaranteed [2] | Higher pricing tiers apply |

| Polyschistine A | Polyschistine A | Bench Chemicals | |

| Hyperelamine A | Hyperelamine A, MF:C34H45NO3, MW:515.7 g/mol | Chemical Reagent | Bench Chemicals |

Table: ME16 Registration Cost Structure (All prices USD)

| Registration Category | IMES Member Early Bird | Non-Member Early Bird | IMES Member Standard | Non-Member Standard |

|---|---|---|---|---|

| Industry Professional, No Hotel | $2,305 | $2,505 | Information not provided | Information not provided |

| Academic, No Hotel | $2,105 | $2,305 | Information not provided | Information not provided |

| Student, No Hotel | $1,085 | $1,185 | Information not provided | Information not provided |

| Industry Professional with Hotel | $3,005 | $3,205 | $3,105 | $3,305 |

| Academic with Hotel | $2,805 | $3,005 | $2,905 | $3,105 |

| Student with Hotel | $1,485 | $1,585 | Sold Out | Sold Out |

Additional Relevant Conferences in the 2025 Landscape

While ME16 serves as the flagship event, several other conferences offer valuable opportunities for metabolic engineering researchers:

Plant Metabolic Engineering Gordon Research Conference (GRC) (June 15-20, 2025): This specialized conference focuses on innovations in plant metabolic engineering for health and sustainability, with programming that includes artificial intelligence integration, plant enzyme engineering, and plant-based foods research [9]. The GRC model emphasizes informal networking and in-depth scientific discussion in a remote location. As of current data, specific abstract and registration deadlines have not been published but typically fall 3-4 months prior to the conference dates.

Institute of Biological Engineering Annual Conference (September 12-13, 2025): This conference in Salt Lake City, Utah includes synthetic biology and metabolic engineering among its technical sessions [14]. The abstract submission deadline is set for June 15, 2025, with registration expected to open following abstract decisions. The conference features a broad biological engineering scope with relevance to metabolic engineering applications.

SEED (Synthetic Biology: Engineering, Evolution & Design) 2025: While specific dates and deadlines are not detailed in available information, this conference represents a leading technical event for synthetic biology with natural overlap to metabolic engineering [28]. The conference typically offers grant opportunities for students, post-docs, and early-career professionals.

Successful abstract submission requires meticulous preparation and adherence to specific methodological frameworks. Based on analysis of conference requirements, the following protocol ensures optimal abstract preparation:

Phase 1: Conceptualization and Strategic Alignment

- Session Topic Mapping: Identify the most appropriate session topic for your research by carefully reviewing the conference's thematic areas [27] [26]. For ME16, this includes specific areas such as "Metabolic Engineering for Health," "Metabolic Engineering for Biofuels and Biochemicals," or "Modeling, Big Data, and Artificial Intelligence."

- Presentation Format Selection: Determine whether oral or poster presentation better suits your research stage and communication goals. Consider that oral presentation deadlines typically occur significantly earlier than poster deadlines [27].

- Contribution Assessment: Evaluate whether your research presents sufficient novelty, unpublished data, and field advancement to warrant submission.

Phase 2: Technical Composition and Optimization

- Title Crafting: Develop a concise, descriptive title not exceeding 150 characters that incorporates essential keywords for discoverability [27]. The title must accurately represent research content while attracting target audience attention.

- Abstract Body Development: Structure the 400-word maximum abstract to include: (1) clear background and specific research objective; (2) precise methodological description with key innovations; (3) definitive results with experimental data; and (4) impactful conclusion stating significance and potential applications [27].

- Author and Affiliation Specification: Collect complete information for all authors and co-authors including full names, institutional affiliations, and email addresses in correct order of contribution [27].

Phase 3: Submission Protocol and Post-Submission Management

- Platform Preparation: Establish necessary accounts in the submission system (e.g., AIChE Confex gateway) well before deadlines to avoid technical complications [27].

- Pre-Submission Review: Verify that all elements meet specified requirements including character counts, word limits, and formatting specifications.

- Confirmation and Editing Management: Retain submission confirmation and utilize the editing window to make improvements until the submission deadline passes [27].

Diagram 1: Abstract Preparation and Submission Workflow. This methodological framework outlines the sequential phases for developing and submitting competitive abstracts to metabolic engineering conferences.

Research Reagent Solutions for Metabolic Engineering Studies

Table: Essential Research Reagents and Materials for Metabolic Engineering Applications

| Reagent/Material Category | Specific Examples | Technical Function in Metabolic Engineering Research |

|---|---|---|

| Genome Editing Tools | CRISPR-Cas systems, TALENs, zinc finger nucleases | Targeted genetic modifications in host organisms for pathway engineering [26] |

| Synthetic Biology Components | Standardized biological parts, promoters, RBS libraries, vectors | Modular construction and optimization of metabolic pathways [29] |

| Enzyme Engineering Systems | Directed evolution kits, computational design software, expression hosts | Improvement of catalytic efficiency and substrate specificity [29] |

| Analytical Standards | MS standards, HPLC calibration kits, NMR reference compounds | Quantitative analysis of metabolic fluxes and product titers [9] |

| Specialized Growth Media | Defined minimal media, high-cell-density formulations | Support of engineered strains under production conditions [9] |

| Pathway Precursors | Isotopically-labeled compounds, intermediate metabolites | Tracer studies for pathway validation and flux analysis [29] |

Funding Opportunity Analysis and Application Methodology

Conference Support Mechanisms and Eligibility Criteria

Securing financial support for conference attendance requires strategic approach to available funding mechanisms with attention to specific eligibility requirements and deadlines:

International Metabolic Engineering Society (IMES) Support Program ME16 offers complementary and steeply discounted registrations through IMES support programs specifically targeting students, post-docs, and early career faculty within the first five years of their professorial appointment [27] [2]. The application deadline for this funding was April 1, 2025, synchronized with the poster abstract deadline [27]. While the application window has closed, this program establishes a precedent for future conference planning, indicating that funding applications typically align with abstract submission timelines.

AIChE Conference Grant Framework The American Institute of Chemical Engineers offers a broader conference grant application system that operates on a quarterly, first-come, first-served basis [30]. This program prioritizes first-time applicants within a calendar year and encourages diversity across gender, ethnicity, sexual orientation, and other minority representations [30]. The application process requires justification of merits and reasons for support, with strong encouragement—though not requirement—of abstract submission prior to application.

NSF Funding Mechanisms for Fundamental Research The NSF Cellular and Biochemical Engineering program supports fundamental engineering research that enables advanced biomanufacturing approaches [29]. While not directly funding conference attendance, this program provides research grants that typically include conference travel budgets. Principal investigators are encouraged to discuss conference, workshop, and supplement requests with program directors before submission [29].

Strategic Funding Application Protocol

Diagram 2: Funding Application Decision Framework. This protocol outlines the strategic pathway for identifying, applying for, and securing conference funding support through various institutional mechanisms.

Advanced Strategic Planning for International Conference Participation

Visa Processing and Logistical Considerations

International conference attendance requires advanced planning for logistical considerations, particularly for the flagship ME16 conference in Copenhagen:

Visa Application Protocol

- Visa Requirement Assessment: Determine entry requirements based on nationality using Denmark's official immigration website [2]. Note that scientific conference attendance typically qualifies as a "cultural visit" rather than business visa.

- Invitation Letter Acquisition: Request official invitation letters from conference organizers by emailing invitationletters@aiche.org with complete information including event name, proof of registration, full name, institutional affiliation, address, date of birth, passport number, and expiration date [2].

- Application Timeline Management: Initiate visa applications minimally 3-4 months before conference dates to accommodate processing variations.

Logistical Planning Framework

- Accommodation Strategy: For ME16, standard registration with hotel includes a 4-night stay at the Tivoli Hotel (June 15-19, 2025) [2]. Additional nights require separate booking with coordination through conference organizers to maintain room continuity.

- Registration Tier Selection: Evaluate early bird versus standard registration considering that hotel availability becomes limited after the May 5, 2025 early bird deadline, with student accommodations with hotel already listed as sold out during standard registration [2].

- Ancillary Event Registration: Reserve space for exclusive conference ticketed events including Tivoli Gardens, Carlsberg Brewery Tour, and Kronberg Castle Tour during registration process [2].

Professional Development Optimization Framework

Maximizing professional return from conference participation requires strategic planning beyond basic attendance:

Scientific Program Engagement Methodology

- Presentation Format Selection: Choose between oral presentations (offering greater visibility but earlier submission deadlines) versus poster presentations (allowing more recent data inclusion and individualized discussion) based on research maturity [27].

- Session Selection Algorithm: Prioritize sessions based on relevance to current research, emerging methodologies, and strategic networking targets. ME16 sessions span from foundational topics like "Metabolic Engineering for Biofuels" to cutting-edge areas like "Modeling, Big Data, and Artificial Intelligence" [26].

- Post-Conference Knowledge Management: Utilize permanent access to conference proceedings for ongoing reference [2]. Document key methodologies, experimental approaches, and computational tools for implementation in home research programs.

Networking and Collaboration Development

- Strategic Connection Planning: Identify and prioritize engagement with researchers from institutions aligned with methodological interests or potential collaborative projects.

- Professional Development Hour Documentation: Request PDH certificates post-conference at 8 PDH per conference day for professional credential maintenance [2].

- Industry Engagement Protocol: Participate in start-up exhibition and pitch competitions for exposure to commercial applications and potential partnership opportunities [2] [26].

Successful navigation of the 2025 metabolic engineering conference landscape requires meticulous attention to interconnected deadlines and strategic planning across abstract development, funding applications, and registration windows. Researchers must prioritize the April 1-2, 2025 poster abstract deadline for ME16 while developing contingency plans for earlier oral abstract submissions. Funding pursuit should align with abstract preparation timelines, recognizing that many support mechanisms require synchronized applications. Early bird registration by May 5, 2025 offers significant cost savings and guaranteed accommodation availability. By implementing the comprehensive frameworks outlined in this technical guide—from abstract preparation methodologies to funding application protocols—metabolic engineering professionals can optimize their conference participation for maximal scientific impact and career advancement within this rapidly evolving field.

Cutting-Edge Tools and Applications: From CRISPR to Industrial Bioprocessing

This technical guide explores advanced genome editing tools central to contemporary metabolic engineering research, framing them within the context of 2025 conference themes such as hierarchical strain engineering and AI-driven design.

The field of metabolic engineering is experiencing its "third wave," characterized by the integration of sophisticated synthetic biology tools to systematically rewire cellular metabolism [31]. This paradigm shift enables the programming of microbial cell factories for sustainable production of biofuels, chemicals, and pharmaceuticals. Multiplex genome editing (MGE)—the simultaneous modification of multiple genomic loci—has emerged as a cornerstone technology for optimizing complex metabolic pathways, moving beyond traditional one-gene-at-a-time approaches [32]. Within this framework, two powerful technologies have proven particularly transformative: the CRISPR/Cas9-facilitated multiplex pathway optimization (CFPO) technique and Multiplex Automated Genome Engineering (MAGE). These systems enable rapid prototyping of engineered strains by creating combinatorial libraries of genetic variants, allowing researchers to explore high-dimensional expression spaces and identify optimal pathway configurations that would be impractical to design rationally [33] [32].

CRISPR/Cas9-Facilitated Multiplex Pathway Optimization (CFPO)

Core Principles and Technological Advantages

The CFPO technique represents a significant advancement for simultaneously modulating expression of multiple genes on the chromosome in prokaryotic systems like E. coli [33]. This system employs two plasmids to target Cas9 to regulatory sequences of pathway genes, combined with a donor DNA plasmid library containing diverse regulatory elements. A key innovation is its modularized plasmid construction strategy that enables assembly of complex donor DNA plasmid libraries. After genome editing, the result is a combinatorial library with variably expressed pathway genes, from which optimal performers can be selected through growth enrichment or screening [33].

Compared to earlier technologies, CFPO offers distinct advantages: (1) it achieves simultaneous modulation of multiple genetic components with high efficiency (70% for three transcriptional units containing four genes); (2) it avoids plasmid burden by integrating modifications directly into the chromosome, enhancing genetic stability for large-scale fermentations; and (3) it eliminates the need for selectable markers in genome editing, streamlining the engineering process [33].

Experimental Protocol: CFPO Implementation

Strain Construction and Library Generation

- Plasmid Assembly: Construct three essential plasmids: pRedCas9 (expressing Cas9 and λ-Red recombinase), pRBSL-genes (donor DNA library with modular RBS sequences), and pgRNA-genes (expressing guide RNAs targeting regulatory sequences) [33].

- Transformation: Co-transform pRedCas9 with pgRNA-genes into the host E. coli strain.

- Induction and Editing: Induce λ-Red recombinase expression with L-arabinose, then transform with the pRBSL-genes donor library to initiate homologous recombination at target sites.

- Selection and Screening: Apply appropriate selection pressure and screen for successful edits. In the xylose utilization case study, improved strains were selected through growth enrichment on xylose minimal media [33].

Key Optimization Parameters

- Guide RNA design should target regulatory regions (promoters, RBS) rather than coding sequences

- Donor DNA library should encompass a wide range of regulatory strength variants

- Efficiency can be enhanced by using high-efficiency recombinase systems and optimizing induction timing

Case Study: Improving Escherichia coli Xylose Utilization Pathway

The CFPO technique was successfully applied to optimize the xylose metabolic pathway in E. coli, which normally exhibits low xylose-utilization rates [33]. Researchers simultaneously modulated three transcriptional units containing four genes: xylAB, tktA, and talB. The resulting combinatorial library was screened through growth enrichment, leading to the identification of strain HQ304. This optimized strain demonstrated a 3-fold increase in xylose utilization rate compared to the parent strain, highlighting CFPO's effectiveness in pathway optimization [33]. Subsequent enzymological analysis revealed the optimal combination of enzyme activities that balanced the metabolic flux, which would have been difficult to predict through rational design alone.

Multiplex Automated Genome Engineering (MAGE)

Multiplex Automated Genome Engineering (MAGE) employs pools of synthetic single-stranded oligonucleotides to introduce multiple simultaneous mutations across the genome [32]. This technology enables rapid prototyping of genetic variants and combinatorial genome engineering, particularly in E. coli. The core mechanism involves using the λ Red recombination system to incorporate oligonucleotides at multiple target sites during DNA replication. To enhance efficiency, host mismatch repair (MMR) pathway proteins (MutS or MutL) are often suppressed or knocked out, preventing excision of newly incorporated mutations [32].

A significant advancement came with the development of pORTMAGE, a generalized broad-host vector that expresses all necessary MAGE components alongside a dominant negative mutant protein MutL from the E. coli MMR system under temperature-controlled promotion [32]. This system efficiently modifies multiple loci without prior host genome modification and minimizes detectable off-target mutagenesis in E. coli and Salmonella enterica [32].

Table 1: MAGE Technical Specifications and Performance Metrics

| Parameter | Specification | Application Notes |

|---|---|---|

| Oligonucleotide Length | Typically 90 bases | Must contain homologous flanking sequences |

| Target Loci | Multiple simultaneous targets | Demonstrated with up to 80 targets in parallel |

| Efficiency Optimization | MMR suppression (ΔmutS) | Increases incorporation efficiency 10-100 fold |

| Cycle Time | Approximately 2-3 hours per cycle | Enables 25+ cycles daily for rapid evolution |

| Host Range | Primarily prokaryotes | Optimized for E. coli, limited eukaryotic applications |

| Key Advantage | Rapid combinatorial diversity | Enables exploration of vast genotypic space |

Hybrid Approach: CRMAGE Technology

CRMAGE represents a hybrid approach that combines λ Red recombineering-based MAGE technology with CRISPR/Cas9 to create a highly efficient and rapid genome engineering method in E. coli [32]. While CRMAGE significantly enhances genome editing efficiency and capability, challenges such as restricted host range and system complexity limit its widespread applications. The CRISPR component introduces counterselection against unmodified cells, dramatically enriching for successfully engineered mutants and reducing screening burden [32].

Comparative Analysis and Integration with Other Technologies

Performance Benchmarking: CFPO vs. MAGE

Table 2: Technology Comparison for Metabolic Pathway Optimization

| Feature | CRISPR/CFPO | MAGE | CRMAGE (Hybrid) |

|---|---|---|---|

| Editing Efficiency | High (70% for 3 loci) [33] | Variable (improved with MMR knockout) [32] | Highest (CRISPR counterselection) [32] |

| Number of Simultaneous Targets | Demonstrated with 3-4 genes [33] | Dozens in parallel [32] | Dozens with high efficiency [32] |

| Chromosomal Integration | Yes (avoids plasmid burden) [33] | Yes (direct chromosomal modification) [32] | Yes (combined approach) [32] |

| Throughput | Moderate | Very high (automated cycles) [32] | High with reduced screening |

| Technical Complexity | Moderate (multiple plasmids) | High (optimization required) | Highest (system integration) |

| Best Application Context | Targeted pathway optimization with defined gene set | Genome-wide diversity generation | Complex engineering with high efficiency requirements |

Synergistic Integration with Adaptive Laboratory Evolution (ALE)

Both CFPO and MAGE show powerful synergies when integrated with Adaptive Laboratory Evolution (ALE). ALE employs controlled serial culturing to promote accumulation of beneficial mutations, complementing targeted genome engineering by optimizing complex phenotypes that are difficult to rationally design [34]. For instance, when integrating non-natural metabolic pathways, rational design often fails due to host rejection responses, while ALE can dynamically adjust selection pressures to identify mutation combinations that balance heterologous pathway expression with host adaptability [34].

A notable example is the work by Gleizer et al. (2019), who constructed an autotrophic E. coli strain by activating the Calvin-Benson-Bassham (CBB) cycle via ALE, concurrently optimizing the formate dehydrogenase (FDH) to ribulose-1,5-bisphosphate carboxylase (Rubisco) activity ratio to enable growth solely on COâ‚‚ [34]. This process involved multi-level regulation that surpassed rational design predictive capacity. Similarly, in antibiotic resistance research, CRISPR was used to create a fitness landscape of E. coli proteins encompassing 260,000 mutations, revealing that approximately 75% of evolutionary pathways could lead to high-resistance phenotypes [34].

The Scientist's Toolkit: Essential Research Reagents

Table 3: Key Research Reagents for Advanced Genome Editing

| Reagent / Tool | Function | Application Notes |

|---|---|---|

| CRISPR/Cas9 System | RNA-guided DNA cleavage | Most versatile genome engineering platform [32] |

| λ Red Recombinase | Facilitates homologous recombination | Essential for both CFPO and MAGE [33] [32] |

| ssDNA Oligonucleotides | Donor templates for incorporation | 90-base length optimal for MAGE [32] |

| MMR-Deficient Strains | Enhance recombination efficiency | ΔmutS or dominant-negative MutL variants [32] |

| Lipid Nanoparticles (LNPs) | In vivo delivery of editing components | Natural liver affinity; enables redosing [35] |

| Base/Prime Editors | DSB-free precision editing | Emerging technologies for multiplex editing [32] |

| crRNA Arrays | Multiplex guide RNA expression | tRNA-based processing enables simultaneous targeting [32] |

| Turbidostat/Chemostat Systems | Automated ALE cultivation | Enables precise control of evolutionary parameters [34] |

| Magnoloside M | Magnoloside M Reference Standard|For Research Use Only | Magnoloside M, a phenylethanoid glycoside from Magnolia officinalis. For Research Use Only. Not for diagnostic or therapeutic use. |

| Sanggenon W | Sanggenon W, MF:C25H26O6, MW:422.5 g/mol | Chemical Reagent |

Future Perspectives and Emerging Trends

The genome editing field continues to evolve rapidly, with several emerging trends shaping its future application in metabolic engineering. The global market for genome editing is expected to grow from $10.8 billion in 2025 to $23.7 billion by 2030, reflecting intense development and commercialization [36]. Key advancements include:

Novel CRISPR Effectors: Beyond Cas9, new variants like CasMINI, Cas12j2, and Cas12k offer improved specificity, smaller sizes for delivery, and expanded targeting capabilities [32]. These systems enable more sophisticated multiplex editing approaches with reduced off-target effects.

Artificial Intelligence Integration: AI algorithms significantly enhance CRISPR precision by predicting optimal guide RNA sequences, identifying potential off-target effects, and developing novel gene editors by analyzing genomic data [37]. AI-driven platforms can optimize gene editing conditions, analyze risks, and provide real-time monitoring to enhance efficiency and safety.

Advanced Delivery Systems: Next-generation delivery platforms including lipid nanoparticles (LNPs), virus-like particles, and metal-organic frameworks are overcoming conventional barriers in in vivo applications [32]. LNPs are particularly promising as they don't trigger immune responses like viral vectors and enable redosing [35].