Native vs. Heterologous Pathways: A Strategic Guide for Efficient Bioproduction

This article provides a comprehensive comparison of native and heterologous pathway efficiency for researchers and drug development professionals.

Native vs. Heterologous Pathways: A Strategic Guide for Efficient Bioproduction

Abstract

This article provides a comprehensive comparison of native and heterologous pathway efficiency for researchers and drug development professionals. It explores the fundamental principles governing pathway selection, from theoretical yield calculations to host-pathway compatibility. The content details advanced methodological tools like CRISPR/Cas9 and computational design, alongside systematic troubleshooting strategies for common bottlenecks in transcription, secretion, and metabolic flux. Through validation frameworks and comparative case studies across diverse systems—including E. coli, Aspergillus niger, and Streptomyces—it offers a practical guide for selecting and optimizing pathways to maximize titer, rate, and yield (TRY) for target molecules, ultimately accelerating strain development for biomedical applications.

Core Concepts and Strategic Selection of Native vs. Heterologous Systems

In metabolic engineering and synthetic biology, the successful implementation of a biosynthetic pathway—whether native or heterologous—is quantitatively evaluated by three critical performance indicators: Titer, Rate, and Yield, collectively known as TRY. These metrics serve as the ultimate benchmark for assessing the economic viability and technical feasibility of bioproduction processes across pharmaceutical, chemical, and energy sectors. Titer represents the final concentration of the target compound achieved in a fermentation batch, directly impacting downstream separation costs. Rate measures the speed of product formation, determining reactor throughput and capital expenditure. Yield reflects the conversion efficiency of substrate to product, dictating raw material utilization costs. This guide provides a comprehensive comparison of pathway efficiency evaluation, presenting standardized metrics, experimental protocols, and analytical frameworks essential for researchers and drug development professionals.

Quantitative TRY Metrics in Native vs. Heterologous Systems

The selection between native and heterologous pathway expression involves critical trade-offs in TRY performance, heavily influenced by host organism compatibility, pathway complexity, and engineering strategies.

Table 1: Comparative TRY Metrics Across Production Systems

| Host System | Product | Titer (g/L) | Rate (g/L/h) | Yield (g/g) | Pathway Type | Key Intervention |

|---|---|---|---|---|---|---|

| Pseudomonas putida | Indigoidine | 25.6 | 0.22 | 0.33 (≈50% theoretical) | Heterologous | 14-gene CRISPRi knockdown [1] |

| Escherichia coli | D-Lactic Acid | - | - | - | Native | Two-stage process optimization [2] |

| Saccharomyces cerevisiae | Artemisinic Acid | - | 0.00417* | - | Heterologous | Multi-gene reconstruction [3] |

| Aspergillus niger | Heterologous Proteins | Varies | Varies | Varies | Heterologous | Multi-dimensional optimization [4] |

Note: The artemisinic acid production rate of 100 mg/L over 24 hours equates to approximately 0.00417 g/L/h [3]. The dash (-) indicates data not explicitly provided in the search results.

Heterologous expression in optimized hosts demonstrates remarkable achievements, exemplified by 25.6 g/L indigoidine production in Pseudomonas putida via minimal cut set (MCS) approach, coupling production to growth and achieving approximately 50% of the maximum theoretical yield [1]. Native pathway engineering leverages existing host metabolism, with two-stage processes in E. coli showing optimized yield and productivity across diverse chemicals [2].

Table 2: Maximum Theoretical Yield (MTY) Calculations for Precursor Metabolites

| Precursor Metabolite | mol product/mol glucose | g product/g glucose | Relevant Native Pathways |

|---|---|---|---|

| α-ketoglutarate | 1.320 | 1.07 | Amino acid biosynthesis [1] |

| Glutamine | 1.141 | 0.93 | Amino acid metabolism [1] |

| Indigoidine | 0.537 | 0.74 | Heterologous pigment production [1] |

Eukaryotic systems offer distinct advantages for complex natural products; Saccharomyces cerevisiae successfully produces artemisinic acid through extensive pathway engineering, achieving a 100 mg/L titer that represents a thousand-fold increase over native plant production [3]. Filamentous fungi like Aspergillus niger serve as exceptional hosts for heterologous protein production through multi-strategy optimization of expression systems, secretion pathways, and metabolic flux [4].

Experimental Protocols for TRY Quantification

Protocol 1: Minimal Cut Set (MCS) Approach for Growth-Coupled Production

The MCS approach computationally identifies reaction interventions that genetically couple product formation to growth, enforcing high yields [1].

- Genome-Scale Modeling: Utilize a genome-scale metabolic model (e.g., iJN1462 for P. putida) and add an in silico reaction for the target heterologous product [1].

- MCS Computation: Apply MCS algorithms to predict minimal reaction sets for elimination, enabling strong growth-coupled production. For indigoidine, this identified 63 solution-sets [1].

- Omics-Guided Feasibility Assessment: Filter solutions using transcriptomic and proteomic data to exclude essential genes and multifunctional proteins, narrowing to experimentally feasible interventions (e.g., 14 reactions targeting 16 genes) [1].

- Multiplex CRISPRi Implementation: Design and express CRISPRi guides for simultaneous knockdown of all target genes [1].

- TRY Assessment in Bioreactors: Evaluate performance in controlled bioreactor systems (e.g., 100-ml shake flasks to 2-L bioreactors) across batch and fed-batch modes, measuring titer (g/L), rate (g/L/h), and yield (g product/g substrate) [1].

Protocol 2: Two-Stage Process Optimization

Dynamic two-stage processes separate growth and production phases to optimize TRY metrics, particularly for native products [2].

- Computational Phenotype Screening: Use frameworks like mcPECASO (microbial chemical Production Enhancement via Complete Analysis of Switchable Operating-points) to scan the phenotypic space and identify optimal growth and production stage phenotypes [2].

- Strain Engineering for Dynamic Regulation: Implement dynamic pathway regulation using inducible promoters or biological sensors to switch from growth to production phenotype [2].

- Bioreactor Process Optimization: Operate bioreactors with an initial growth stage (maximizing biomass accumulation) followed by a triggered production stage. Monitor biomass, substrate consumption, and product formation throughout [2].

- Flux Analysis: Analyze intracellular flux distributions to identify key reaction perturbations (e.g., in PEP and NADPH availability) that enhance production phenotypes [2].

- TRY Metric Calculation: Calculate titer (end-of-batch concentration), rate (total product/(volume * time)), and yield (product produced/substrate consumed) for process validation [2].

Visualizing Pathway Analysis and Engineering Workflows

Diagram: MCS-Based Strain Engineering Workflow

Diagram: Two-Stage Bioprocess Optimization

Computational and Analytical Tools for Pathway Analysis

Advanced computational frameworks are indispensable for predicting pathway efficiency and guiding engineering strategies.

Table 3: Computational Tools for Pathway Analysis and TRY Prediction

| Tool/Method | Category | Primary Function | Application in TRY Optimization |

|---|---|---|---|

| Minimal Cut Set (MCS) | Constraint-Based Modeling | Predicts reaction knockouts for growth-coupled production | Identifies intervention strategies for high-yield strains [1] |

| mcPECASO | Bioprocess Simulation | Compares one-stage vs. two-stage processes | Identifies optimal phenotypic targets for enhanced TRY [2] |

| Flux Balance Analysis (FBA) | Constraint-Based Modeling | Predicts flux through metabolic reactions | Calculates maximum theoretical yields and analyzes network capabilities [1] |

| Pathway Topology-Based (PTB) Methods | Pathway Analysis | Incorporates pathway structure in omics data analysis | More robust identification of impacted pathways than non-TB methods [5] [6] |

| e-DRW (Entropy-based Directed Random Walk) | Pathway Activity Inference | Infers pathway activities from gene expression | High reproducibility in identifying biologically relevant pathways [6] |

Computational analyses reveal that two-stage processes with intermediate growth during production consistently achieve optimal TRY values, even when substrate uptake is limited by reduced growth [2]. mcPECASO simulations demonstrate these processes outperform single-stage strategies across diverse metabolites. Pathway Topology-Based (PTB) methods outperform non-topology-based approaches in robustness and reproducibility, with e-DRW showing superior performance in identifying biologically relevant pathways from gene expression data [6].

The Scientist's Toolkit: Essential Research Reagents and Solutions

Successful pathway engineering requires specialized genetic tools, hosts, and analytical platforms.

Table 4: Essential Research Reagents and Solutions for TRY Optimization

| Reagent/Solution | Function | Application Example |

|---|---|---|

| Multiplex CRISPRi System | Simultaneous knockdown of multiple genes | Implementing 14-gene knockdown for indigoidine production in P. putida [1] |

| Genome-Scale Metabolic Models | In silico prediction of metabolic capabilities | iJN1462 model for P. putida; E. coli core model [1] [2] |

| Redαβγ Recombineering System | Precise DNA editing with short homology arms | BGC modification in E. coli strains for heterologous expression [7] |

| Inducible Promoter Systems | Temporal control of gene expression | Dynamic pathway regulation in two-stage processes [2] |

| RMCE Cassettes (Cre-lox, Vika-vox, Dre-rox) | Site-specific genomic integration | Multi-copy BGC integration in Streptomyces chassis strains [7] |

| Optimized Chassis Strains | Clean genetic background for heterologous expression | S. coelicolor A3(2)-2023 with deleted endogenous BGCs [7] |

| Conjugative Transfer Systems | DNA transfer between species | oriT-mediated plasmid transfer from E. coli to Streptomyces [7] |

| Spermatinamine | Spermatinamine, MF:C33H44Br4N6O7, MW:956.4 g/mol | Chemical Reagent |

| TGR5 agonist 5 | TGR5 agonist 5, MF:C22H26N2O2, MW:350.5 g/mol | Chemical Reagent |

Specialized E. coli strains enable both modification and conjugative transfer of biosynthetic gene clusters (BGCs) to optimized chassis strains like S. coelicolor A3(2)-2023, facilitating heterologous natural product discovery and yield improvement [7]. Advanced genetic toolkits including recombinase-mediated cassette exchange (RMCE) systems enable stable, multi-copy integration of large DNA constructs across diverse microbial hosts [7].

The systematic evaluation of titer, rate, and yield provides the critical foundation for comparing pathway efficiency across native and heterologous expression systems. The experimental and computational frameworks presented—from MCS-based strain design to two-stage process optimization—offer researchers standardized methodologies for TRY quantification and enhancement. As synthetic biology and metabolic engineering advance, integrated approaches combining computational prediction, multiplex genome engineering, and bioprocess optimization will continue to push the boundaries of achievable TRY metrics, enabling more efficient and economically viable bioproduction pipelines for pharmaceuticals, chemicals, and fuels.

In the pursuit of engineering biological systems for natural product synthesis and therapeutic development, researchers face a fundamental choice: utilize the native host that evolved alongside the biosynthetic pathway or engineer a heterologous host with more favorable technological characteristics. This decision hinges critically on the complex cellular environment that governs protein function, particularly the inherent balance of cofactors and the capacity for appropriate post-translational modifications (PTMs). These elements form an intricate regulatory landscape that is exceptionally difficult to reconstitute in non-native systems [8].

PTMs are biochemical modifications that occur after protein synthesis—such as phosphorylation, ubiquitination, glycosylation, and acetylation—that can significantly alter protein structure, function, stability, localization, and interactions with other molecules [9] [10]. Similarly, cofactor balance refers to the available pools of essential helper molecules (e.g., SAM for methylation, ATP for phosphorylation) and the protein cofactors that assist in enzymatic functions. Together, these elements create a native host advantage that is often underestimated in pathway engineering efforts [11].

This review examines the experimental evidence demonstrating how native hosts provide an optimized environment for biosynthetic pathways through their inherent cofactor balance and PTM machinery, comparing these advantages to the challenges faced when transferring pathways to heterologous systems.

The PTM Landscape: Regulatory Complexity in Native Systems

Diversity and Function of Post-Translational Modifications

Post-translational modifications represent a crucial regulatory layer that expands functional proteomic diversity far beyond what is encoded in the genome. While the human genome comprises approximately 20,000-25,000 genes, the proteome is estimated to encompass over 1 million proteins, with PTMs being a primary mechanism for this expansion [10]. More than 650 types of protein modifications have been described, with phosphorylation, ubiquitination, glycosylation, acetylation, and methylation being among the most extensively studied [12].

These modifications activate or inactivate intracellular processes by:

- Altering protein structure and function: PTMs can significantly change protein conformation, creating or obscuring binding sites [9].

- Regulating protein localization: Modifications can serve as trafficking signals, directing proteins to specific cellular compartments [10].

- Controlling protein stability: Modifications like ubiquitination target proteins for degradation, while others can enhance stability [13].

- Mediating protein-protein interactions: PTMs can create docking sites for other proteins or disrupt existing interactions [9].

In the context of virus-host interactions, PTMs have been particularly well-characterized, revealing how viruses hijack host PTM machinery to modify viral proteins, promoting viral replication and evading immune surveillance [9] [13]. This intricate interplay demonstrates the sophistication of native PTM systems that have evolved to respond to complex cellular demands.

PTM Regulation of Key Cellular Processes

The regulatory potential of PTMs is exemplified in their control of fundamental cellular processes. Phosphorylation, catalyzed by protein kinases and reversed by phosphatases, plays critical roles in regulating cell cycle, growth, apoptosis, and signal transduction pathways [10] [12]. The human genome encodes 518 protein kinases that target primarily serine, threonine, and tyrosine residues [12].

Histone modifications represent another well-characterized PTM system where methylation, acetylation, and phosphorylation control epigenetic regulation and gene expression [14]. In Saccharomyces cerevisiae, a system of four methyltransferases (Set1p, Set2p, Set5p, and Dot1p) and four demethylases (Jhd1p, Jhd2p, Rph1p, and Gis1p) carefully controls histone methylation patterns [14]. Research has shown these enzymes are themselves extensively post-translationally modified, with 75 phosphorylation sites, 92 acetylation sites, and two ubiquitination sites identified across these regulatory proteins, suggesting complex feedback mechanisms [14].

Table 1: Major Types of Post-Translational Modifications and Their Functions

| PTM Type | Enzymes Responsible | Primary Functions | Amino Acids Targeted |

|---|---|---|---|

| Phosphorylation | Kinases, Phosphatases | Signal transduction, enzymatic regulation | Serine, Threonine, Tyrosine |

| Ubiquitination | E1, E2, E3 ligases | Protein degradation, signaling | Lysine |

| Acetylation | Acetyltransferases, Deacetylases | Transcriptional regulation, metabolic control | Lysine |

| Methylation | Methyltransferases, Demethylases | Epigenetic regulation, protein-protein interactions | Lysine, Arginine |

| Glycosylation | Glycosyltransferases | Protein folding, cell adhesion, recognition | Asparagine, Serine, Threonine |

Cofactor Interactions: The Native Balance Advantage

The Role of Cofactors in Cellular Processes

Cofactors comprise a diverse group of non-protein molecules that assist in enzymatic reactions, including metal ions, coenzymes, and prosthetic groups. The inherent balance of these cofactors in native hosts creates an optimized environment for biosynthetic pathways that is exceptionally challenging to replicate in heterologous systems.

The AAA+ ATPase p97 provides an excellent case study in complex cofactor regulation. This hexameric ATPase participates in diverse cellular activities including DNA replication, repair, and protein quality control pathways [11]. p97's functional diversity is regulated by numerous regulatory cofactors that associate with either its N-terminal domain or C-terminus, targeting the enzyme to specific cellular pathways [11]. These cofactors sometimes require simultaneous association with more than one binding partner, creating a sophisticated control system that depends on the native host's precise cofactor balance.

The regulation of p97 exemplifies how native hosts maintain cofactor specificity and diversity through multiple mechanisms, including bipartite binding, binding site competition, changes in oligomeric assemblies, and nucleotide-induced conformational changes [11]. These intricate relationships ensure proper temporal and spatial control of essential cellular processes.

Challenges in Reconstituting Cofactor Balance

Heterologous hosts often lack the appropriate balance of cofactors necessary for optimal function of transplanted biosynthetic pathways. This imbalance can manifest as:

- Insufficient cofactor production: Heterologous hosts may not produce required cofactors in necessary quantities [3].

- Incorrect subcellular localization: Cofactors may not be properly localized to support the biosynthetic pathway [8].

- Missing regulatory partners: Essential protein cofactors that modulate activity may be absent [11].

- Incompatible redox environments: The cellular environment may not support the required oxidation-reduction reactions [3].

These challenges are particularly evident in the production of plant-derived natural products in microbial hosts. Plant metabolic networks are highly complex and possess enhanced post-translational modification ability alongside rigorous gene regulation, unlike microbes [3]. When reconstructing these pathways in heterologous hosts, persistent regulation of gene clusters and metabolic flux balance presents a fundamental hurdle [3].

Experimental Comparisons: Native vs. Heterologous Systems

Quantitative Analysis of Pathway Performance

Direct experimental comparisons between native and heterologous hosts reveal significant performance disparities that underscore the native advantage. The following table summarizes key findings from multiple studies:

Table 2: Comparative Performance of Native vs. Heterologous Hosts for Natural Product Production

| Natural Product | Native Host | Heterologous Host | Titer in Native Host | Titer in Heterologous Host | Key Limiting Factors |

|---|---|---|---|---|---|

| Fredericamycin A (FDM A) | Streptomyces griseus ATCC 49344 | Streptomyces albus J1074 | 170 mg/L [8] | 130 mg/L [8] | Regulatory network disruption |

| Fredericamycin A (with fdmR1 overexpression) | Streptomyces griseus ATCC 49344 | Streptomyces lividans K4-114 | ~1,000 mg/L [8] | 1.4 mg/L [8] | Cofactor availability, transcriptional bottlenecks |

| Artemisinic acid | Artemisia annua | S. cerevisiae (engineered) | Low (plant source) | 100 mg/L [3] | Precursor availability, enzyme compatibility |

| FDM A (with fdmR1 + fdmC overexpression) | Streptomyces griseus | Streptomyces lividans | ~1,000 mg/L [8] | 17 mg/L [8] | Specific enzyme deficiency (fdmC) |

The fredericamycin A case study is particularly illuminating. While heterologous expression in Streptomyces albus J1074 achieved a respectable 130 mg/L titer compared to 170 mg/L in the native producer, other heterologous hosts struggled considerably [8]. In Streptomyces lividans K4-114, the fdm cluster was completely silent until the pathway-specific regulator fdmR1 was overexpressed, and even then titers reached only 0.5 mg/L—over 300-fold lower than the native host with similar genetic manipulation [8].

Further investigation revealed that regulatory disparities between hosts significantly impacted production. Comparison of transcription levels identified fdmC, a ketoreductase, as a critical bottleneck in the heterologous host [8]. Only when both fdmR1 and fdmC were co-overexpressed did production in S. lividans increase to 17 mg/L—a 12-fold improvement but still substantially lower than native production [8]. This demonstrates how native hosts maintain optimized transcriptional networks that support pathway efficiency.

Analysis of PTM Disparities Between Systems

Differences in PTM capacity between native and heterologous hosts significantly impact pathway performance. The p97 ATPase illustrates this point, as its function is modulated by various PTMs including SUMOylation, ubiquitylation, palmitoylation, acetylation, and phosphorylation [11]. These modifications fine-tune p97's diverse molecular activities and interactions with regulatory cofactors.

In viral infection models, PTM differences determine infection outcomes. RNA viruses, which lack enzymes for introducing PTMs to their proteins, hijack host PTM machinery to promote their survival [13]. Viruses such as chikungunya, dengue, zika, HIV, and coronavirus all depend on host-mediated PTMs for successful infection [13]. This demonstrates the highly specialized nature of PTM systems and their crucial role in determining protein function.

Table 3: Mass Spectrometry-Based PTM Identification Workflow

| Step | Technique | Purpose | Key Considerations |

|---|---|---|---|

| Protein Preparation | Homologous overexpression and purification | Obtain sufficient protein material for analysis | Maintain native PTM patterns during purification |

| Proteolytic Digestion | Multiple enzymes (trypsin, LysargiNase, Asp-N, chymotrypsin) | Generate peptides of suitable lengths for analysis | Different enzymes provide complementary coverage |

| PTM Enrichment | Immunoaffinity purification (e.g., phospho-specific antibodies) | Isolate modified peptides from complex mixtures | Specificity and efficiency of enrichment critical |

| Mass Spectrometry | LC-MS/MS with HCD and EThcD fragmentation | Identify modification sites and types | Orthogonal fragmentation improves site localization |

| Data Analysis | Database searching with PTM filters | Confidently identify modification sites | Stringent score and localization probability cutoffs |

Methodologies for Investigating Native Advantage

Proteomic Approaches for PTM Characterization

Mass spectrometry-based proteomics has become the cornerstone technology for comprehensive PTM analysis. Advanced workflows now enable researchers to systematically characterize modification sites across the proteome. A study on Saccharomyces cerevisiae histone modification enzymes employed a combinatorial mass spectrometric approach involving four proteolytic digestions (trypsin, LysargiNase, Asp-N, and chymotrypsin) and two mass spectrometry fragmentation methods (higher-energy collisional dissociation and electron transfer/HCD) [14].

This orthogonal approach achieved near-complete protein sequence coverage (>90% for four enzymes, >85% for two others), allowing comprehensive identification of PTM sites that would be missed with single-method approaches [14]. The methodology revealed that phosphorylation was absent or underrepresented on catalytic and other structured domains but strongly enriched in intrinsically disordered regions, suggesting a role in modulating protein-protein interactions rather than direct catalytic effects [14].

Diagram 1: Comprehensive PTM analysis workflow using mass spectrometry.

Metabolic Engineering and Pathway Transfer Techniques

Engineering heterologous hosts for natural product production requires sophisticated genetic tools and a deep understanding of pathway regulation. The process typically involves:

- Pathway identification and characterization: Determining the complete set of genes required for biosynthesis [15].

- Vector assembly: Clustering genes into expressible constructs with appropriate regulatory elements [8].

- Host transformation: Introducing DNA into the heterologous host [15].

- Pathway optimization: Balancing gene expression, cofactor supply, and precursor availability [3].

- Fermentation development: Scaling production and optimizing growth conditions [3].

A "pressure test" to produce 10 natural products in 90 days highlighted the significant knowledge gap in our understanding of interactions between biosynthetic gene clusters and host regulatory systems [8]. Successful examples of heterologous production are dominated by small, low-complexity gene clusters with few operons, while more complex pathways often fail to function optimally outside their native context [8].

The Scientist's Toolkit: Essential Research Reagents

Table 4: Key Research Reagent Solutions for PTM and Cofactor Studies

| Reagent/Category | Specific Examples | Primary Function | Application Notes |

|---|---|---|---|

| PTM Enrichment Kits | Pierce Phosphoprotein Enrichment Kit, Ubiquitin Enrichment Kit | Isolate modified proteins from complex mixtures | Critical for detecting low-abundance modified species [10] |

| Modification-Specific Antibodies | Anti-phospho-serine/threonine/tyrosine, anti-acetyl-lysine | Detect and quantify specific PTMs | Enable Western blot, immunofluorescence applications [10] |

| Mass Spectrometry Standards | TMT/Label-free quantitation standards, synthetic heavy peptides | Quantify PTM changes across conditions | Essential for rigorous quantitative comparisons [14] |

| Proteolytic Enzymes | Trypsin, LysargiNase, Asp-N, Chymotrypsin | Protein digestion for MS analysis | Orthogonal enzymes improve sequence coverage [14] |

| Cofactor Analogs | SAM analogs, ATP analogs, NAD+ precursors | Probe cofactor-dependent reactions | Can reveal mechanism and identify dependencies |

| Pathway Refactoring Tools | BioBricks, Synthetic DNA assemblies | Reconstruct pathways in heterologous hosts | Enable modular pathway design and optimization [3] |

| Egfr-IN-117 | Egfr-IN-117, MF:C25H30BrN7O2S, MW:572.5 g/mol | Chemical Reagent | Bench Chemicals |

| Biotin sodium | Biotin sodium, CAS:56085-82-6, MF:C10H15N2NaO3S, MW:266.29 g/mol | Chemical Reagent | Bench Chemicals |

The inherent cofactor balance and PTM capacity of native hosts creates a sophisticated regulatory environment that is exceptionally challenging to replicate in heterologous systems. Experimental evidence from natural product biosynthesis, viral infection models, and fundamental cell biology consistently demonstrates that native host advantage stems from deeply integrated regulatory networks rather than individual component superiority.

For researchers and drug development professionals, these findings highlight both challenges and opportunities. While heterologous hosts offer technical conveniences including rapid growth, genetic tractability, and simplified process development, their implementation for complex pathways requires careful consideration of cofactor compatibility and PTM capacity [8]. Strategic approaches may include:

- Comprehensive profiling of PTM patterns and cofactor requirements in native hosts before pathway transfer

- Engineering cofactor biosynthesis in heterologous hosts to match native balance

- Utilizing intermediate hosts that more closely resemble native PTM machinery

- Developing screening systems to identify heterologous hosts with compatible modification systems

As proteomic technologies continue to advance, particularly in mass spectrometry-based PTM analysis, our understanding of the native host advantage will deepen, potentially enabling more sophisticated engineering of heterologous systems that can mimic these optimized environments. Until then, recognizing the fundamental importance of inherent cofactor balance and post-translational modifications remains essential for successful pathway engineering and biopharmaceutical development.

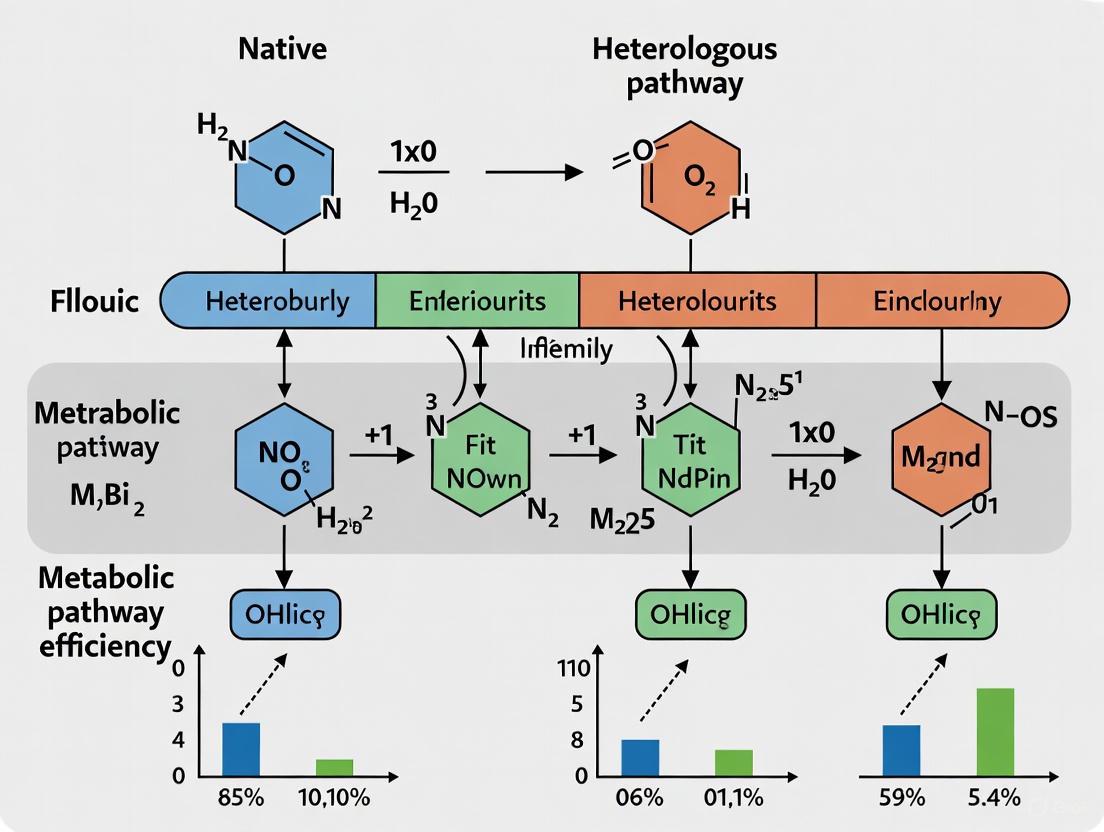

Diagram 2: Native versus heterologous host regulatory environments determining pathway efficiency.

The pursuit of efficient and scalable production systems for complex biochemicals and therapeutic proteins represents a central challenge in modern biotechnology. While native producers often possess the innate machinery for synthesis, they frequently present significant limitations in terms of genetic tractability, scalability, and industrial robustness. Heterologous expression—the introduction of foreign genetic pathways into genetically amenable host organisms—has emerged as a transformative strategy to overcome these barriers. This approach leverages the natural biosynthesis capabilities of source organisms while harnessing the favorable fermentation characteristics and well-established genetic tools of industrial workhorse strains [16].

The fundamental promise of heterologous hosts lies in their potential to overcome two persistent bottlenecks in bioprocess development: scalability challenges associated with fastidious native producers and genetic manipulation barriers encountered in genetically recalcitrant organisms. By refactoring metabolic pathways from diverse biological sources into optimized chassis cells, researchers can achieve unprecedented levels of production control, process consistency, and yield optimization. This guide provides a systematic comparison of heterologous expression platforms, supported by experimental data and methodological details, to inform strategic host selection for biotechnological applications ranging from pharmaceutical production to sustainable chemical manufacturing.

Comparative Performance Analysis of Heterologous Expression Systems

Quantitative Comparison of Protein Production Yields

Extensive research has demonstrated that the selection of an appropriate heterologous host system profoundly impacts the final yield and functionality of target proteins and metabolites. The table below summarizes key performance metrics across diverse host platforms as reported in recent studies:

Table 1: Comparative Performance of Heterologous Expression Systems

| Host Organism | Target Product | Yield Achieved | Key Genetic Modifications | Production Scale | Reference |

|---|---|---|---|---|---|

| Aspergillus niger (AnN2 chassis) | Lingzhi-8 (LZ8) medical protein | 110.8 mg/L | 13/20 TeGlaA gene copies deleted, PepA protease disruption | 50 mL shake-flask | [17] |

| Aspergillus niger (AnN2 chassis) | Thermostable pectate lyase A (MtPlyA) | 416.8 mg/L | Multi-copy integration at native high-expression loci, Cvc2 overexpression | 50 mL shake-flask | [17] |

| Ogataea minuta (double mutant) | Human Serum Albumin (HSA) | 7.5 g/L | Prb1 protease and alcohol oxidase (AOX1) knockout, chaperone co-expression | 21 days, production phase | [18] |

| Engineered PVX vector in N. benthamiana | Green Fluorescent Protein (GFP) | 0.50 mg/g fresh weight | Integration of heterologous viral suppressor of RNA silencing (NSs) | Laboratory scale | [19] |

| Bacillus subtilis 168 | Functional nitrogenase | Acetylene reduction activity detected | Native promoter replacement with Pveg | Laboratory scale | [20] |

Platform Efficiency and Applications Analysis

Beyond absolute yield metrics, the strategic selection of heterologous hosts depends on multiple factors including product complexity, required post-translational modifications, and scalability requirements. The following table provides a comparative analysis of platform characteristics:

Table 2: Heterologous Host System Capabilities and Applications

| Host System | Optimal Product Classes | Key Advantages | Documented Limitations | Typical Development Timeline | |

|---|---|---|---|---|---|

| Filamentous Fungi (A. niger) | Industrial enzymes, eukaryotic proteins, secondary metabolites | Exceptional protein secretion capacity, GRAS status, strong promoters | High background endogenous protein secretion, complex genetics | 6-12 months for strain engineering | [17] [16] |

| Methylotrophic Yeasts (O. minuta, P. pastoris) | Therapeutic proteins, antibodies, complex eukaryote proteins | High-density cultivation, strong inducible promoters, eukaryotic PTMs | Potential hyperglycosylation, protease activity issues | 3-6 months for process optimization | [18] |

| Plant-Based Systems (N. benthamiana) | Vaccine antigens, viral proteins, pharmaceutical proteins | Scalability, biosafety, cost-effective biomass | Lower recombinant protein yields, plant-specific glycosylation | Rapid expression (days-weeks) | [19] |

| Gram-Positive Bacteria (B. subtilis) | Enzymes, metabolic pathway products, nitrogen fixation | Well-characterized genetics, industrial robustness, PGPR properties | Limited complex PTM capability, secretion bottlenecks | 3-9 months for pathway refactoring | [20] |

Experimental Protocols and Methodologies

CRISPR/Cas9-Mediated Chassis Development in Aspergillus niger

The development of high-yielding Aspergillus niger chassis strains exemplifies the systematic optimization of heterologous hosts for improved protein production [17]. The experimental workflow involves:

Strain Engineering Protocol:

- Parental Strain Selection: Begin with an industrial glucoamylase-producing A. niger strain (AnN1) containing 20 copies of the heterologous glucoamylase (TeGlaA) gene.

- Gene Copy Reduction: Employ CRISPR/Cas9-assisted marker recycling to delete 13 of the 20 TeGlaA gene copies, creating a low-background production host.

- Protease Disruption: Disrupt the major extracellular protease gene (PepA) to minimize target protein degradation.

- Validation: Confirm the resulting chassis strain (AnN2) exhibits 61% reduction in extracellular protein and significantly reduced glucoamylase activity while retaining multiple transcriptionally active integration loci.

- Pathway Integration: Integrate target genes into high-expression loci formerly occupied by TeGlaA genes using modular donor DNA plasmids with native AAmy promoter and AnGlaA terminator.

Secretory Pathway Enhancement: Overexpression of Cvc2, a COPI vesicle trafficking component, can further enhance production yields by 18%, demonstrating the value of combining genomic engineering with secretory pathway optimization [17].

Process Optimization in Yeast Expression Systems

The development of high-yielding Ogataea minuta strains for industrial protein production demonstrates the critical importance of systematic process optimization [18]:

Fermentation Optimization Protocol:

- Host Strain Development: Generate double mutant lacking Prb1 protease and alcohol oxidase (AOX1) to reduce protein degradation and optimize metabolic efficiency.

- Chaperone Co-expression: Introduce plasmids co-overexpressing chaperones (Pdi1, Ero1, and Kar2) to facilitate proper protein folding.

- Fed-Batch Process Development:

- Implement controlled feeding of carbon and nitrogen sources to maintain optimal growth and production phases

- Establish precise pH control throughout fermentation

- Optimize dissolved oxygen levels through aeration and agitation control

- Scale-Up Strategy: Transfer optimized conditions from laboratory scale to industrial-scale manufacturing (4500 L bioreactor) while maintaining critical process parameters.

Key Performance Metrics: This optimized system achieved approximately 7.5 g/L of Human Serum Albumin after 21 days in the production phase, successfully demonstrating industrial-scale manufacturability for a candidate biologic protein [18].

Pathway Refactoring for Nitrogen Fixation in Bacillus subtilis

The functional expression of nitrogen-fixing capabilities in Bacillus subtilis illustrates the challenges and solutions for complex pathway transplantation [20]:

Heterologous Cluster Expression Protocol:

- Cluster Identification: Mine genome of Paenibacillus polymyxa CR1 to identify 11 kb nitrogen-fixing (nif) gene cluster (nifB to nifV, containing 9 genes).

- Synthetic Assembly: Synthesize and assemble nif cluster using ExoCET (exonuclease combined with RecET recombination) technology.

- Chromosomal Integration: Integrate assembled cluster into genome of Bacillus subtilis 168 via double-exchange recombination.

- Transcription Validation: Confirm nif cluster transcription via RT-PCR.

- Promoter Engineering: Replace native promoter with host-derived constitutive promoter Pveg to restore nitrogenase activity detected via acetylene reduction assay.

Critical Finding: Simple transfer of the nif cluster with its native promoter resulted in transcription but no detectable nitrogenase activity, highlighting that functional heterologous expression often requires optimization of regulatory elements beyond simple gene transfer [20].

The Scientist's Toolkit: Essential Research Reagents

Successful implementation of heterologous expression systems requires specialized reagents and genetic tools. The following table catalogues essential research reagents referenced in the cited studies:

Table 3: Essential Research Reagents for Heterologous Expression Studies

| Reagent/Tool | Specific Example | Function/Application | Experimental Context |

|---|---|---|---|

| CRISPR/Cas9 System | Marker recycling, multi-copy gene deletion | Precision genome editing for chassis development | A. niger strain engineering [17] |

| Modular Donor DNA Plasmids | AAmy promoter, AnGlaA terminator | Site-specific integration of target genes | A. niger platform construction [17] |

| Viral Suppressors of RNA Silencing (VSRs) | NSs, P19, P38 from plant viruses | Enhance transgene expression by countering host RNA silencing | Plant viral vector optimization [19] |

| ExoCET Assembly Technology | Direct cloning of large gene clusters | Assembly and integration of large DNA constructs | B. subtilis nif cluster integration [20] |

| Constitutive Promoters | Pveg, P43, Ptp2 | Drive heterologous gene expression in new host context | Nitrogenase activation in B. subtilis [20] |

| Molecular Chaperones | Pdi1, Ero1, Kar2 | Facilitate proper protein folding, prevent aggregation | O. minuta HSA production [18] |

| Fed-Batch Fermentation System | Controlled nutrient feeding, pH monitoring | Optimized production at laboratory and industrial scale | O. minuta process development [18] |

| Casein hydrolysate | Casein hydrolysate, MF:C21H41N5O11, MW:539.6 g/mol | Chemical Reagent | Bench Chemicals |

| I-Bop | I-Bop, MF:C23H29IO5, MW:512.4 g/mol | Chemical Reagent | Bench Chemicals |

Comparative Workflow and Strategic Decision Pathways

The selection of an appropriate heterologous expression strategy depends on multiple factors including target molecule complexity, required yield, and available resources. The following diagram illustrates the key decision points and strategic pathways:

The experimental data and methodologies presented demonstrate that heterologous expression systems have matured into powerful platforms for overcoming the scalability and genetic manipulation barriers inherent in native producers. The key to success lies in matching the target product characteristics with the appropriate host system and implementing systematic optimization strategies that address both genetic and process-level factors.

For industrial enzyme production, the engineered Aspergillus niger platform offers exceptional yields through its optimized secretion machinery and strong native promoters. For therapeutic protein production, the Ogataea minuta system provides eukaryotic processing capabilities with demonstrated industrial scalability. For rapid response applications such as vaccine antigen production, plant-based systems with enhanced viral vectors deliver compelling advantages in speed and cost-effectiveness. Finally, for metabolic engineering applications requiring the transfer of complex biosynthetic pathways, promoter optimization and careful cluster refactoring in amenable hosts like Bacillus subtilis can overcome the functional expression barriers that often plague simple gene transfer approaches.

The continued advancement of genetic tools, particularly CRISPR-based systems, combined with sophisticated process optimization strategies, promises to further expand the capabilities of heterologous expression platforms. This will enable increasingly efficient bioproduction of complex molecules across the pharmaceutical, industrial enzyme, and sustainable chemical sectors.

The pursuit of efficient microbial cell factories hinges on the precise calculation and comparison of theoretical maximum yields (TMY) for biosynthetic pathways. TMY represents the stoichiometrically maximum amount of a product that can be formed from a given substrate, computed based on the metabolic network of a host organism. In industrial bioprocessing, accurately determining whether pathway yields of various products can surpass inherent stoichiometric limits is fundamental to strain design and process optimization. Research demonstrates that introducing appropriate heterologous reactions can improve product pathway yields in over 70% of biosynthetic scenarios across hundreds of products and multiple industrial organisms [21].

The emergence of sophisticated computational frameworks has transformed yield prediction from theoretical exercise to practical engineering tool. Genome-scale metabolic models (GEMs) comprehensively represent an organism's metabolism, enabling yield calculation through flux balance analysis (FBA). However, traditional single-species GEMs possess inherent limitations—they incorporate only species-specific reactions, restricting exploration of heterologous pathway introductions to enhance yield beyond native capabilities. This limitation has spurred development of cross-species metabolic networks and specialized algorithms that quantitatively evaluate yield enhancement strategies across diverse hosts and substrates [21].

Understanding the distinction between native pathway yields and heterologously-enhanced yields provides critical insights for metabolic engineering. Native pathway yields are constrained by the host's existing metabolic architecture, while heterologous pathway integration can bypass these constraints through carbon-conserving and energy-conserving strategies. This comparative analysis explores the quantitative foundations of yield calculation methodologies, directly compares native versus heterologous pathway performance across case studies, and details experimental protocols for yield validation—providing researchers with a comprehensive framework for pathway efficiency assessment [21].

Core Concepts and Computational Methodologies

Foundational Principles of Yield Calculation

Theoretical maximum yield (TMY) represents the stoichiometric ceiling for product formation from a substrate within a defined metabolic network. Pathway yield (YP) quantifies the actual amount of product formed from a substrate based on host stoichiometry, serving as a crucial metric for designing efficient, atom-economical cell factories. The producibility yield (YP0) defines the yield limit of a product from a substrate in a host without introducing heterologous reactions beyond the minimal set essential for non-native product synthesis. The relationship between these parameters—where YP approaches YP0 in native pathways and can potentially exceed it through heterologous interventions—forms the basis for yield enhancement strategies [21].

The maximum theoretical yield (MTY) derived from genome-scale models provides a more accurate assessment than simpler calculation methods because it accounts for the complete physiological processes competing for cellular resources. For instance, when calculating MTY for indigoidine production from glucose in Pseudomonas putida, the model considers competing demands for precursors and cofactors like glutamine and flavin mononucleotide (FMN), resulting in more realistic yield expectations than pathway-only calculations [22].

Computational Frameworks for Yield Prediction

Flux Balance Analysis (FBA) serves as the cornerstone computational method for yield prediction, using linear programming to optimize flux distribution through metabolic networks toward a biological objective (typically biomass or product formation). FBA operates under the pseudo-steady state assumption, where metabolite concentrations remain constant while fluxes distribute through the network. Implementation requires a stoichiometric matrix representing all metabolic reactions, exchange reactions defining substrate uptake and product secretion, and constraints defining reaction directionality and capacity [22] [23].

Flux Variability Analysis (FVA) extends FBA by determining the range of possible fluxes through each reaction while maintaining optimal objective function value, identifying alternative optimal flux distributions and evaluating network flexibility. This is particularly valuable for identifying non-unique flux solutions in complex networks. Minimal Cut Set (MCS) approaches identify minimal reaction intervention sets that couple metabolite production strongly to growth, theoretically enforcing product formation even under suboptimal growth conditions. MCS analysis revealed that approximately 99% of producible metabolites in P. putida could potentially be growth-coupled, though this percentage decreases substantially when higher minimum product yields are specified [22].

Cross-Species Metabolic Network (CSMN) models address limitations of single-organism GEMs by integrating metabolic reactions across multiple species, enabling exploration of heterologous reactions for yield enhancement. The Quantitative Heterologous Pathway Design algorithm (QHEPath) specifically evaluates how heterologous reactions can enhance yields beyond native limits, systematically calculating yield improvements across thousands of biosynthetic scenarios [21].

Table 1: Key Computational Methods for Yield Prediction

| Method | Primary Function | Applications | Limitations |

|---|---|---|---|

| Flux Balance Analysis (FBA) | Optimizes flux distribution toward biological objective | TMY calculation, pathway feasibility assessment | Assumes steady-state metabolism, requires objective function definition |

| Flux Variability Analysis (FVA) | Determines flux ranges through reactions while maintaining optimality | Identifies alternative optimal pathways, evaluates network flexibility | Computationally intensive for large networks |

| Minimal Cut Set (MCS) | Identifies minimal reaction interventions for growth-coupled production | Designing obligatory production strains, identifying essential knockouts | Solutions may be biologically infeasible; requires manual curation |

| QHEPath Algorithm | Quantifies heterologous pathway yield enhancements | Systematic evaluation of yield improvement strategies across hosts | Dependent on quality of cross-species metabolic model |

Figure 1: Computational Workflow for Yield Prediction - This diagram illustrates the integration of multiple computational methods for determining theoretical maximum yields and identifying yield enhancement strategies.

Quantitative Comparison: Native vs. Heterologous Pathway Yields

Systematic Analysis of Yield Enhancement Potential

Large-scale computational studies evaluating 12,000 biosynthetic scenarios across 300 products and 4 substrates in 5 industrial organisms reveal that introducing appropriate heterologous reactions can improve product pathway yields in over 70% of cases. Thirteen distinct engineering strategies have been identified, categorized as carbon-conserving and energy-conserving, with five strategies effective for over 100 different products. This systematic analysis demonstrates the broad applicability of heterologous interventions for breaking native stoichiometric yield limits [21].

The non-oxidative glycolysis (NOG) pathway exemplifies a carbon-conserving strategy that enhances yield by minimizing carbon loss as COâ‚‚. When introduced into E. coli, the NOG pathway increased poly(3-hydroxybutyrate) (PHB) yield beyond the native network stoichiometry limit. Similarly, farnesene yield was enhanced in engineered strains by incorporating the NOG pathway, demonstrating the consistent yield-enhancing potential of this heterologous system across different products [21].

Case Study Comparisons

Indigoidine Production in Pseudomonas putida: Native production of the blue pigment indigoidine in P. putida is negligible without pathway engineering. Through MCS-based metabolic rewiring requiring 14 simultaneous reaction interventions implemented via multiplex-CRISPRi, researchers achieved strong growth-coupled production reaching 25.6 g/L titer, 0.22 g/L/h productivity, and approximately 50% of the maximum theoretical yield (0.33 g indigoidine/g glucose). This engineered heterologous system shifted production from stationary to exponential phase and maintained performance across scales from shake flasks to bioreactors [22].

Taxifolin Biosynthesis in Yarrowia lipolytica: Heterologous biosynthesis of the flavonoid taxifolin in engineered Y. lipolytica demonstrated the iterative improvement potential of combined metabolic engineering and computational modeling. Initial engineering yielded 26.4 mg/L taxifolin at 1 g/L naringenin substrate. Subsequent stable genomic integration of key genes increased yield to 34.9 mg/L, with additional modifications identified through FBA (overexpression of GND1 and IDP2, knockout of LIP2) increasing yields by 94% and 155% respectively. Optimization of cultivation conditions in tri-baffled shake flasks further enhanced yield by 120%, demonstrating the cumulative benefit of systematic heterologous pathway optimization [23].

10-HDA Production in Escherichia coli: Engineering E. coli for 10-hydroxy-2-decenoic acid (10-HDA) production faced limitations from product feedback inhibition due to its antimicrobial activity. Heterologous expression of the MexHID transporter protein from Pseudomonas aeruginosa enhanced product efflux, reduced intracellular toxicity, and increased substrate conversion rate to 88.6%, achieving 0.94 g/L 10-HDA titer through fed-batch cultivation. This transporter engineering strategy specifically addressed a yield limitation not resolvable through native mechanisms [24].

Table 2: Comparative Yield Data for Native versus Heterologous Pathways

| Product | Host Organism | Native Pathway Yield | Heterologous Pathway Yield | Enhancement Strategy |

|---|---|---|---|---|

| Indigoidine | Pseudomonas putida | Negligible native production | 0.33 g/g glucose (50% MTY) | MCS-based growth coupling (14 gene knockdowns) |

| Taxifolin | Yarrowia lipolytica | Non-native product | 34.9 mg/L at 1 g/L substrate | Stable genomic integration + FBA-guided optimization |

| 10-HDA | Escherichia coli | Limited by feedback inhibition | 0.94 g/L (88.6% conversion) | Heterologous transporter expression (MexHID) |

| Poly(3-hydroxybutyrate) | Escherichia coli | Limited by native stoichiometry | Exceeded native yield limit | Non-oxidative glycolysis pathway |

| Farnesene | Engineered strain | Limited by native stoichiometry | Exceeded native yield limit | Non-oxidative glycolysis pathway |

Experimental Protocols for Yield Determination

Genome-Scale Metabolic Model Reconstruction

High-quality metabolic model construction begins with comprehensive reaction database compilation. The BiGG database provides a universal model containing 15,638 metabolites and 28,301 reactions spanning 108 GEMs across 35 species. Initial preprocessing incorporates critical details including metabolite charge, formula information, and reaction directions. Thermodynamic and heuristic corrections ensure biologically plausible reaction directions—287 reaction directions were corrected using Gibbs free energy data, while 271 were adjusted based on heuristic rules [21].

Automated quality control workflows eliminate errors enabling infinite metabolite generation, a common issue in uncurated models. The parsimonious enzyme usage FBA (pFBA) method identifies and removes problematic reactions through iterative penalty application, threshold satisfaction checks, and systematic reaction restoration to pinpoint specific error sources. This produces metabolic networks capable of accurate yield prediction without thermodynamic impossibilities [21].

Heterologous Pathway Design and Validation

The QHEPath algorithm quantitatively evaluates heterologous reactions for enhancing yields beyond native limits. Implementation involves: (1) calculating producibility yield (YP0) without heterologous additions; (2) determining maximum pathway yield (YMP) using the CSMN model; (3) identifying specific heterologous reactions that bridge the gap between YP0 and YMP; (4) categorizing yield-enhancing strategies as carbon-conserving or energy-conserving; (5) validating biological feasibility through literature support and experimental testing [21].

The SubNetX algorithm addresses complex molecule biosynthesis by extracting and assembling balanced subnetworks from biochemical databases. This approach connects target molecules to host metabolism through multiple precursors while maintaining stoichiometric feasibility. The workflow involves: (1) preparing a network of elementally balanced reactions; (2) graph search for linear core pathways; (3) expansion and extraction of balanced subnetworks linking cosubstrates to native metabolism; (4) host integration; (5) ranking feasible pathways by yield, enzyme specificity, and thermodynamic feasibility [25].

Figure 2: Heterologous Pathway Design Workflow - This diagram outlines the systematic process for designing, balancing, and ranking heterologous pathways for integration into host organisms.

Yield Validation Methodologies

Fermentation experiments provide experimental yield validation under controlled conditions. For taxifolin production in Y. lipolytica, researchers employed shake flask fermentations with defined media, sampling at regular intervals to quantify product accumulation and substrate depletion. Optimal taxifolin yield (10%) was observed at 200 mg/L naringenin substrate concentration, with maximum absolute yield of 26.4 mg/L at 1 g/L naringenin [23].

Advanced bioreactor systems enable yield validation under industrially relevant conditions. Indigoidine production in P. putida maintained high yield across scales—from 100-mL shake flasks to 250-mL ambr systems and 2-L bioreactors—demonstrating scalability of the engineered heterologous system. Fed-batch cultivation with controlled nutrient feeding further enhanced 10-HDA production in E. coli to 0.94 g/L, highlighting the importance of cultivation strategy in realizing theoretical yield potential [22] [24].

Analytical quantification employs specialized techniques for different products. Indigoidine measurement utilized spectrophotometric analysis at 612 nm with appropriate standard curves. Taxifolin and intermediates (eriodictyol, dihydrokaempferol) quantification employed HPLC with UV/Vis or mass spectrometry detection. 10-HDA analysis likely used GC-MS or LC-MS methods suitable for hydroxy fatty acid detection [22] [23] [24].

Research Reagent Solutions for Yield Studies

Table 3: Essential Research Reagents for Yield Determination Experiments

| Reagent/Category | Specific Examples | Application in Yield Studies |

|---|---|---|

| Genome-Scale Metabolic Models | iJN1462 (P. putida), BiGG Database | Provide computational framework for theoretical yield calculations and host-pathway interactions |

| Computational Algorithms | QHEPath, SubNetX, MCS, FBA | Identify yield-enhancing interventions, design heterologous pathways, calculate flux distributions |

| Genetic Engineering Tools | CRISPRi, Cre-loxP, Chromosomal integration (MUCICAT) | Implement metabolic interventions, stabilize gene expression, control gene dosage |

| Host Organisms | E. coli, P. putida, Y. lipolytica, S. cerevisiae | Provide metabolic background for pathway testing, offer diverse metabolic capabilities |

| Analytical Techniques | SEC-HPLC, DLS, GC-MS, LC-MS, Spectrophotometry | Quantify product formation, assess protein aggregation, measure metabolite concentrations |

| Specialized Cultivation Systems | Tri-baffled shake flasks, ambr systems, Fed-batch bioreactors | Optimize oxygen transfer, scale production, maintain optimal substrate concentrations |

| Heterologous Pathways | Non-oxidative glycolysis, MexHID transporter, BpsA synthetase | Enhance carbon efficiency, improve product efflux, enable non-native product synthesis |

Quantitative comparison of theoretical maximum yields between native and heterologous pathways reveals a consistent pattern: native metabolism imposes stoichiometric constraints that heterologous interventions can systematically overcome. Computational analyses demonstrate that over 70% of products can benefit from yield enhancement through strategic heterologous reactions, with carbon-conserving and energy-conserving strategies offering the most significant improvements [21].

The integration of sophisticated computational frameworks with experimental validation provides a powerful methodology for yield optimization. MCS approaches successfully couple product formation to growth, QHEPath algorithms quantitatively evaluate heterologous interventions, and SubNetX designs balanced pathways for complex molecules. Together, these tools enable researchers to not only predict theoretical yield limits but also implement practical engineering strategies to approach those limits [21] [25] [22].

For researchers pursuing yield optimization, the recommended workflow begins with accurate TMY calculation using validated genome-scale models, proceeds through identification of appropriate heterologous interventions using specialized algorithms, implements these interventions with stable genetic engineering approaches, and validates yields under industrially relevant cultivation conditions. This systematic approach maximizes the probability of achieving yields that approach theoretical limits while maintaining performance across scales—the fundamental requirement for economically viable bioprocesses.

The successful heterologous production of valuable compounds, from therapeutics to secondary metabolites, hinges on a fundamental principle: the compatibility between the engineered pathway and the host organism. Simply introducing foreign genes into a host is rarely sufficient for high-yield production [16]. The host's inherent physiology, including its native metabolic network and precursor availability, can impose significant bottlenecks. Consequently, assessing and engineering this host-pathway compatibility is a critical step in metabolic engineering, enabling researchers to select optimal chassis organisms and design strategies that maximize the efficiency of heterologous biosynthesis [26].

Comparative Analysis of Host Organisms for Heterologous Expression

Selecting a suitable host organism is a foundational decision in metabolic engineering. The ideal chassis provides a conducive environment for the heterologous pathway to function, encompassing the necessary precursors, energy, cofactors, and cellular machinery for proper protein folding and modification [16].

Key Host Organisms and Their Characteristics

The table below summarizes the primary hosts used in heterologous expression, detailing their core competencies and limitations.

Table 1: Comparison of Common Host Organisms for Heterologous Expression

| Host Organism | Key Advantages | Major Limitations | Common Species | Ideal Application Examples |

|---|---|---|---|---|

| Escherichia coli | Fast growth; simple, low-cost culture; high protein yield; extensive genetic tools [27] [28] | Limited post-translational modifications; formation of inclusion bodies; inefficient secretion [27] | BL21(DE3) | Prokaryotic proteins; non-glycosylated therapeutics; commodity chemicals [28] |

| Yeast (e.g., S. cerevisiae, P. pastoris) | Eukaryotic PTMs; generally recognized as safe (GRAS); good protein secretion; relatively fast growth [16] [29] | Hyperglycosylation (high mannose); tougher cell wall; lower diversity of native secondary metabolites [16] | Saccharomyces cerevisiae, Pichia pastoris | Eukaryotic enzymes; subunit vaccines; complex natural products [16] [29] |

| Filamentous Fungi | Exceptional protein secretion; high diversity of native secondary metabolites [16] [17] | Complex genetics; high background of native proteins and metabolites [16] [17] | Aspergillus niger | Industrial enzymes (e.g., glucoamylase); fungal natural products [17] |

| Mammalian Cells | Most complex human-like PTMs (e.g., sialic acid); proper protein folding [27] | Slow growth; high cost; complex culture conditions; low yield [16] [27] | CHO (Chinese Hamster Ovary) cells | Complex biopharmaceuticals (e.g., monoclonal antibodies, growth factors) [27] |

| Plant-Based Systems | Eukaryotic PTMs; cost-effective and scalable; self-sufficient as whole organisms [16] [27] | Slow growth (whole organism); complex transformation [16] | Nicotiana benthamiana | Plant natural products; edible vaccines; therapeutic proteins [16] [27] |

Quantitative Host Capacity Evaluation

Beyond qualitative traits, selecting a host can be guided by computational predictions of metabolic capacity. A 2025 study comprehensively evaluated the innate abilities of five major industrial microorganisms to produce 235 different bio-based chemicals [26]. The analysis calculated two key metrics: the maximum theoretical yield (YT), which is the stoichiometric maximum, and the maximum achievable yield (YA), which accounts for the energy required for cell growth and maintenance [26].

Table 2: Metabolic Capacity of Selected Hosts for Representative Chemicals (Glucose, Aerobic) Data adapted from a comprehensive evaluation of microbial cell factories [26]

| Target Chemical | B. subtilis | C. glutamicum | E. coli | P. putida | S. cerevisiae |

|---|---|---|---|---|---|

| L-Lysine (mol/mol Glc) | 0.8214 | 0.8098 | 0.7985 | 0.7680 | 0.8571 |

| L-Glutamate (mol/mol Glc) | Data Suggests C. glutamicum is Industry Standard | High | Medium | Medium | Medium |

| Mevalonic Acid | Host performance varies significantly by chemical | Host performance varies significantly by chemical | Host performance varies significantly by chemical | Host performance varies significantly by chemical | Often Highest |

This systematic evaluation reveals that while S. cerevisiae often shows the highest yield for many chemicals, the optimal host is chemical-specific. For instance, Corynebacterium glutamicum remains the industrial standard for L-glutamate production despite not always having the highest theoretical yield, highlighting the importance of integrating computational predictions with known industrial performance and tolerance [26].

Experimental Protocols for Assessing Host Physiology and Precursor Supply

Once a host is selected, rigorous experimental workflows are required to evaluate and engineer host-pathway compatibility. The following protocols are central to this process.

Protocol: Genome-Scale Metabolic Modeling (GEM) for Pathway Validation

GEMs are computational representations of an organism's entire metabolic network. They are invaluable for in silico prediction of host physiology after pathway insertion [30] [26].

Detailed Methodology:

- Model Reconstruction: Utilize a previously curated GEM for the host organism (e.g., iML1515 for E. coli or iMM904 for S. cerevisiae).

- Pathway Incorporation: Add the heterologous reactions for the target product to the model, ensuring all reactions are mass and charge-balanced. For non-native pathways, this may require adding transport reactions for new metabolites [26].

- Constraint Definition: Set constraints to reflect the experimental condition, including:

- Carbon source uptake rate (e.g., glucose).

- Oxygen uptake rate (for aerobic/anaerobic conditions).

- ATP maintenance requirements (NGAM) [26].

- Simulation and Analysis: Perform Flux Balance Analysis (FBA) to predict metabolic fluxes. The objective is typically set to maximize biomass (to simulate growth) or the secretion rate of the target product. This identifies:

- Theoretical Yield (YT): Max product per carbon source without growth.

- Achievable Yield (YA): Max product yield while maintaining a minimum growth rate [26].

- Precursor Availability: Flux through key nodal metabolites like acetyl-CoA or malonyl-CoA.

- Potential Knockout Targets: Gene deletions that may force flux toward the product [31].

Protocol: Dynamic Metabolic Flux Analysis Using Machine Learning

Traditional GEMs often simulate steady-state conditions. A 2025 approach integrates kinetic models of the heterologous pathway with GEMs to predict dynamic host-pathway interactions [30].

Detailed Methodology:

- Kinetic Model Development: Construct an ordinary differential equation (ODE)-based model for the heterologous pathway, incorporating enzyme kinetics and regulatory loops.

- Integration with GEM: Dynamically couple the kinetic model with the host's GEM. The GEM provides the "global metabolic state" (e.g., energy and redox cofactor levels), which influences the kinetic model's reaction rates [30].

- Machine Learning Surrogate: To reduce the high computational cost of repeatedly solving the GEM, train a surrogate machine learning model (e.g., a neural network) to predict the GEM outputs based on a subset of inputs [30].

- Application: Use the integrated model to:

- Screen the impact of genetic perturbations (e.g., gene knockouts) over time.

- Optimize dynamic control circuits that adjust pathway expression in response to metabolite levels [30].

Diagram: Workflow for Dynamic Host-Pathway Modeling. This diagram illustrates the integration of genome-scale and kinetic models with machine learning to predict dynamic interactions [30].

Engineering Host Compatibility: From Assessment to Implementation

Assessment identifies bottlenecks; engineering solves them. Advanced genetic and synthetic biology tools are used to rewire host physiology for optimal production.

Strategies for Enhancing Precursor Supply

A common bottleneck is the limited supply of central carbon metabolites that serve as precursors for the heterologous pathway.

- Amplifying Native Precursor Pools: Overexpressing enzymes in native pathways (e.g., for acetyl-CoA or malonyl-CoA) can increase flux toward the precursor [31].

- Engineering Cofactor Regeneration: The balance of cofactors (NADPH/NADH, ATP) is crucial. Introducing heterologous transhydrogenases or engineering NADH kinases can alter the cofactor pool to favor the biosynthetic pathway [17] [31].

- Dynamic Regulatory Circuits: Instead of constitutive overexpression, genetic circuits can be designed to dynamically regulate pathway expression. For example, a metabolite biosensor can trigger enzyme expression only when the precursor is abundant, preventing imbalance and toxic intermediate accumulation [31].

Diagram: Dynamic Circuit for Flux Control. A feedback loop where a biosensor detects low precursor levels and triggers enzyme expression to rebalance metabolism [31].

Case Study: Optimizing an Aspergillus niger Chassis for Heterologous Protein Expression

A 2025 study exemplifies a systematic approach to host engineering [17]. Researchers started with an industrial A. niger strain (AnN1) producing high levels of native glucoamylase. To create a superior chassis for heterologous protein expression (AnN2), they employed CRISPR/Cas9 to:

- Reduce Background: Delete 13 of the 20 genomic copies of the native glucoamylase gene, reducing background protein secretion by 61% [17].

- Protease Knockout: Disrupt the major extracellular protease gene (PepA) to minimize degradation of the target heterologous protein [17].

- Utilize High-Expression Loci: Integrate genes for four diverse heterologous proteins (e.g., glucose oxidase, a thermostable pectate lyase) into the genomic loci formerly occupied by the deleted glucoamylase genes, leveraging their strong native regulatory elements [17].

- Enhance Secretion: Overexpress Cvc2, a component of the COPI vesicle trafficking system, which further enhanced the production of one target protein by 18% by optimizing the secretory pathway [17].

This multi-pronged strategy demonstrates how directly engineering host physiology—by reducing competitive pathways, stabilizing products, and enhancing trafficking—can dramatically improve heterologous expression yields.

The Scientist's Toolkit: Essential Reagents and Solutions

This table lists key materials and tools critical for conducting research in host physiology and heterologous pathway engineering.

Table 3: Key Research Reagent Solutions for Host-Pathway Compatibility Studies

| Reagent / Tool | Function / Application | Example Use-Case |

|---|---|---|

| CRISPR/Cas9 System | Precision genome editing for gene knockouts, knock-ins, and regulatory sequence changes. | Disrupting native protease genes in A. niger to enhance heterologous protein stability [17]. |

| Genome-Scale Metabolic Model (GEM) | In silico prediction of metabolic flux, yield, and identification of engineering targets. | Predicting maximum achievable yield of L-lysine in S. cerevisiae and identifying potential gene knockout targets [26]. |

| Modular Cloning Vectors | Standardized assembly of genetic constructs with promoters, genes, and terminators. | Rapidly assembling heterologous pathway genes with different promoter strengths for optimization in E. coli [17] [31]. |

| Metabolite Biosensors | Genetic components that produce a detectable signal (e.g., fluorescence) in response to a specific metabolite. | Dynamically regulating a pathway enzyme in response to precursor availability to balance metabolism [31]. |

| Cell-Free Expression Systems | In vitro transcription/translation system for rapid protein production and pathway prototyping. | Expressing and analyzing enzyme variants without the constraints of cell viability, useful for toxic proteins [32]. |

| mCMY416 | mCMY416, MF:C30H35N3O2, MW:469.6 g/mol | Chemical Reagent |

| Opadotina | Opadotina, MF:C58H93N7O14, MW:1112.4 g/mol | Chemical Reagent |

The journey to efficient heterologous production is guided by the "compatibility imperative." Success is not merely a function of the introduced pathway itself, but of its nuanced interaction with the host's physiological landscape. A systematic workflow—starting with computational host selection using tools like GEMs, followed by experimental assessment and sophisticated engineering of precursor pools, cofactors, and dynamic regulatory circuits—is essential. As synthetic biology tools advance, the ability to precisely model and rewire host physiology will continue to blur the line between native and heterologous metabolism, paving the way for more predictable and high-yielding microbial cell factories.

Implementation Toolkit: From Pathway Design to Host Engineering

The quest for efficient microbial production of valuable chemicals and therapeutics hinges on a central dilemma in metabolic engineering: whether to optimize a host's native metabolic pathways or to introduce entirely heterologous pathways from other organisms. Native pathways often benefit from pre-existing regulatory and metabolic networks, potentially leading to higher initial yields and host compatibility. In contrast, heterologous pathways unlock access to a vastly broader chemical space, enabling the production of novel compounds not naturally synthesized by the host but can place significant stress on the cellular machinery. Computational pathway design has emerged as the critical discipline for navigating this complex decision matrix, providing the data-driven insights needed to rationally select, engineer, and optimize pathways for industrial-scale production. By leveraging the power of biological big-data and retrosynthesis algorithms, researchers can now move beyond traditional trial-and-error approaches, systematically designing efficient microbial cell factories [33] [34] [35].

This guide objectively compares the computational frameworks and experimental methodologies at the forefront of this field. It details how the integration of expansive biological databases with sophisticated prediction models is transforming our ability to evaluate pathway efficiency, focusing squarely on the quantitative comparison between native and heterologous biosynthesis routes. The subsequent sections provide a detailed breakdown of the key computational tools, present comparative yield data, outline standardized experimental protocols for validation, and visualize the core workflows that underpin this rapidly advancing discipline.

The Computational Toolkit: Databases and Retrosynthesis Engines

The foundation of computational pathway design rests on comprehensive biological databases and advanced retrosynthesis software. These tools enable researchers to predict viable metabolic routes and select optimal enzymes for pathway construction.

Table 1: Foundational Biological Databases for Pathway Design

| Data Category | Database Name | Primary Function | Key Utility in Pathway Design |

|---|---|---|---|

| Compounds | PubChem [34] | Stores chemical structures, properties, and biological activities | Identifies target molecules and precursor compounds |

| ChEBI [34] | Focuses on small molecular entities of biological interest | Provides curated chemical data for metabolic intermediates | |

| Reactions/Pathways | KEGG [34] | Maps genes and molecules to metabolic pathways | Analyzes native metabolic networks and identifies connection points |

| MetaCyc [34] | A curated database of metabolic pathways and enzymes | Serves as a reference for known biochemical reactions | |

| Rhea [34] | A manually curated resource of biochemical reactions | Provides explicit, balanced biochemical reaction equations | |

| Enzymes | BRENDA [34] | Comprehensive enzyme information database | Informs enzyme selection with functional data (e.g., kinetics, specificity) |

| UniProt [34] | Central hub for protein sequence and functional data | Provides access to protein sequences for enzyme sourcing | |

| AlphaFold DB [34] | Database of highly accurate protein structure predictions | Aids in enzyme engineering and substrate docking studies | |

| Isomalt (Standard) | Isomalt (Standard), MF:C24H48O22, MW:688.6 g/mol | Chemical Reagent | Bench Chemicals |

| Docetaxel-d5 | Docetaxel-d5, MF:C43H53NO14, MW:812.9 g/mol | Chemical Reagent | Bench Chemicals |

Retrosynthesis software forms the core of the de novo design process. These tools operate on principles similar to organic chemistry retrosynthesis, working backwards from a target molecule to identify plausible precursor molecules and the biochemical reactions that could connect them. A key challenge in this field is moving beyond simple heuristic metrics of synthesizability and towards models that explicitly predict feasible synthetic pathways, a consideration that is especially critical for novel classes of molecules like functional materials [36]. Algorithmic retrosynthesis can explore the vast space of possible heterologous pathways, often discovering routes that would be non-intuitive to human designers. The most advanced systems integrate directly with the databases in Table 1 to ensure that predicted reactions are enzymatically plausible, checking against known enzymatic functions or using physics-based models to propose novel but feasible enzyme activities [34] [35].

Quantitative Comparison of Pathway Efficiency

Theoretical yield calculations provide a crucial first-principles metric for comparing native and heterologous pathways. These calculations help researchers select the most promising routes before committing to costly laboratory experiments.

Table 2: Theoretical Yield Comparison: Native C1 Metabolism vs. Synthetic Pathways Data adapted from a quantitative comparison of aerobic and anaerobic C1 bioconversion routes [33]

| Pathway Type | Host Organism Type | C1 Substrate | Target Product | Max Theoretical Yield (mol/mol) | Key Advantage |

|---|---|---|---|---|---|

| Native | Acetogen | COâ‚‚ | Acetate | High | Minimal metabolic burden, high resilience |

| Native | Methylotroph | Methanol | Succinate | Medium | Efficient carbon utilization |

| Synthetic | Engineered E. coli | Methanol | 1,2-Propanediol | Variable | Access to non-native products |

| Synthetic | Engineered Yarrowia | Formate | Fatty Alcohols | Variable | Tailored for high-value chemicals |

Empirical data from implemented pathways reveals the real-world performance of these designs. Yields can vary significantly based on the host organism, the complexity of the pathway, and the efficiency of its expression and regulation.