A Practical Guide to FBA Model Selection for E. coli Metabolic Networks

Selecting the appropriate Flux Balance Analysis (FBA) model is a critical, yet complex, step for researchers leveraging Escherichia coli metabolic networks in systems biology and drug discovery.

A Practical Guide to FBA Model Selection for E. coli Metabolic Networks

Abstract

Selecting the appropriate Flux Balance Analysis (FBA) model is a critical, yet complex, step for researchers leveraging Escherichia coli metabolic networks in systems biology and drug discovery. This article provides a comprehensive framework for E. coli FBA model selection, catering to the needs of scientists and drug development professionals. We cover foundational principles, from understanding core FBA concepts to navigating different genome-scale models like iML1515 and iDK1463. The guide then delves into methodological applications for tasks such as gene essentiality prediction and drug target identification, followed by strategies for troubleshooting common issues and optimizing predictions through hybrid machine-learning approaches. Finally, we synthesize best practices for model validation and comparative analysis, empowering researchers to make informed, reproducible, and biologically relevant choices for their specific projects.

Understanding the Core Principles of FBA and E. coli Metabolic Networks

Core Principles of Constraint-Based Modeling

Constraint-Based Modeling (CBM) is a computational approach in systems biology that uses genome-scale metabolic models (GEMs) to predict cellular behavior. GEMs are mathematical representations of an organism's metabolism, containing a comprehensive set of biochemical reactions, metabolites, and genes based on its genome annotation [1]. The most widely used framework within CBM is Flux Balance Analysis (FBA), which predicts metabolic flux distributions under steady-state conditions [1] [2].

FBA operates on the principle that metabolic networks reach a steady state where the total flux of metabolites into a reaction equals the outflux. This is mathematically represented by the equation S·v = 0, where S is the stoichiometric matrix and v is the flux vector [1]. The solution space is constrained by reaction directionality and capacity limits. FBA identifies an optimal flux distribution that maximizes a specific cellular objective, typically biomass production for microbial growth [1] [2]. This optimization problem is solved using linear programming solvers.

Comparative Analysis of FBA Methodologies

The table below compares the core and advanced FBA methodologies used in metabolic engineering and systems biology.

Table 1: Comparison of FBA Methodologies and Applications

| Methodology | Core Approach | Key Advantages | Documented Applications | Experimental Validation |

|---|---|---|---|---|

| Standard FBA [1] [2] | Linear programming with a single objective (e.g., biomass max.) | Computationally efficient, widely applicable | Prediction of growth rates, gene essentiality, and metabolic capabilities | Consistent qualitative predictions of gene knock-outs |

| TIObjFind [2] | Integrates Metabolic Pathway Analysis (MPA) with FBA; uses Coefficients of Importance (CoIs) | Infers context-specific objective functions; aligns predictions with experimental data | Case study on Clostridium acetobutylicum fermentation; multi-species IBE system | Reduced prediction error vs. experimental flux data |

| NEXT-FBA [3] | Hybrid approach using ANN trained on exometabolomic data to constrain intracellular fluxes | Improves prediction of intracellular fluxes with minimal input data for pre-trained models | Chinese hamster ovary (CHO) cell metabolism; identification of metabolic shifts | Outperformed existing methods in predicting intracellular fluxes validated by 13C data |

| Neural-Mechanistic Hybrid [4] | Embeds FBA within an Artificial Neural Network (ANN) architecture | Overcomes the "curse of dimensionality"; requires small training datasets | Growth prediction of E. coli and Pseudomonas putida in different media; gene knock-out phenotypes | Systematically outperformed classical FBA in quantitative phenotype predictions |

Experimental Protocols for FBA Validation

Protocol for TIObjFind Framework

The TIObjFind framework provides a methodology for inferring metabolic objectives from experimental data [2].

- Step 1: Single-Stage Optimization: Candidate objective functions (coefficient vectors c) are evaluated using a Karush-Kuhn-Tucker (KKT) formulation of FBA. This step minimizes the squared error between predicted fluxes (v) and experimental flux data (v_exp).

- Step 2: Mass Flow Graph Generation: The FBA solution from Step 1 is used to construct a directed, weighted Mass Flow Graph (MFG) representing the metabolic fluxes between reactions.

- Step 3: Metabolic Pathway Analysis (MPA): A minimum-cut algorithm (e.g., Boykov-Kolmogorov) is applied to the MFG to identify essential pathways and compute Coefficients of Importance (CoIs). These CoIs act as pathway-specific weights in the objective function.

This protocol was implemented in MATLAB, with visualization performed using Python's pySankey package [2].

Protocol for Neural-Mechanistic Hybrid Model

This protocol outlines the training of hybrid models like NEXT-FBA and AMNs to improve flux predictions [3] [4].

- Data Collection: Gather a training set of experimental data. This can be exometabolomic data (NEXT-FBA) or a set of measured flux distributions (Neural-Mechanistic).

- Neural Network Processing: The data is fed into an Artificial Neural Network (ANN). In NEXT-FBA, the ANN relates exometabolomic data to intracellular flux constraints. In the AMN, a neural layer computes an initial flux vector (V₀) from medium composition.

- Mechanistic Layer Execution: The output from the neural layer is processed by a mechanistic solver (e.g., a quadratic programming solver) that ensures the flux solution adheres to the stoichiometric (S·v = 0) and boundary constraints of the GEM.

- Model Training: The entire hybrid architecture is trained end-to-end. The loss function minimizes the difference between the model's predicted fluxes (V_out) and the experimentally measured fluxes, while also penalizing violations of the mechanistic constraints.

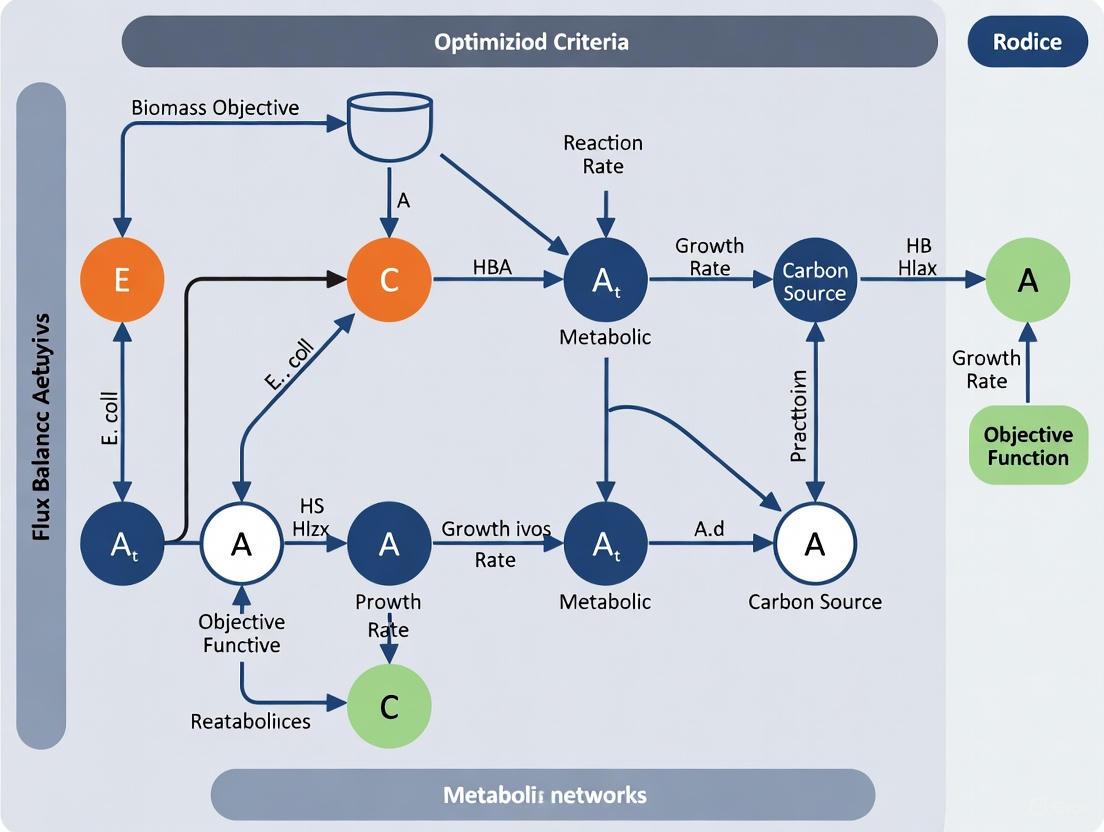

Diagram 1: Workflow of a neural-mechanistic hybrid FBA model. The model is trained by comparing its predictions to experimental data, creating a feedback loop that improves accuracy.

FBA Model Selection forE. coliMetabolic Networks

Selecting an appropriate GEM is the first critical step for FBA studies on E. coli. Researchers must choose between genome-scale and compact, manually curated models based on their specific needs [5].

Table 2: Comparison of E. coli Metabolic Models for FBA

| Model Name | Type & Origin | Reactions / Genes | Key Features | Recommended Use Case |

|---|---|---|---|---|

| iML1515 [5] | Genome-Scale Reconstruction | 2,712 reactions / 1,515 genes | Comprehensive coverage; template for smaller models | Studies requiring full metabolic network; gene essentiality analysis |

| iCH360 [5] | Compact, Manually Curated | Covers central metabolism & biosynthesis pathways | "Goldilocks-sized"; enriched with thermodynamic & kinetic data; highly interpretable | Enzyme-constrained FBA; EFM analysis; reference for metabolic engineering |

| ECC2 [5] | Medium-Scale (Algorithmically reduced from iJO1366) | Reduced set from iJO1366 | Retains key phenotypic features | General-purpose modeling where iML1515 is too large |

The integration of additional biological constraints is a key trend for improving predictive power. Enzyme-enabled FBA incorporates proteomic limitations, while Thermodynamics-based FBA excludes thermodynamically infeasible cycles [1] [5]. For researchers focusing on E. coli core metabolism, the iCH360 model provides an optimal balance between coverage and curability, making it suitable for advanced FBA applications [5].

Table 3: Key Research Reagent Solutions for Constraint-Based Modeling

| Resource / Tool Name | Type | Function in FBA Research |

|---|---|---|

| COBRA Toolbox [1] | Software Package | A MATLAB suite providing the core computational environment for performing FBA and other constraint-based analyses. |

| COBRApy [5] | Software Package | A Python version of the COBRA toolbox, enabling model reconstruction, simulation, and analysis. |

| AGORA [1] | Model Repository | A database of high-quality, curated GEMs for various microbial species, used for retrieving or validating models. |

| BiGG Models [1] | Model Database | A knowledgebase of standardized, genome-scale metabolic models, useful for comparing nomenclature and reactions. |

| CarveMe [1] | Software Tool | An automated pipeline for reconstructing metabolic models directly from genomic data. |

| Gapseq [1] | Software Tool | An automated tool for drafting metabolic models and annotating metabolic pathways from genome sequences. |

| MetaNetX [1] | Software Platform | A platform that provides a unified namespace for metabolic model components, helping to integrate models from different sources. |

Diagram 2: A typical workflow for reconstructing and using a Genome-scale Metabolic Model (GEM), from genome annotation to simulation.

Flux Balance Analysis (FBA) is a mathematical approach for analyzing the flow of metabolites through metabolic networks, particularly genome-scale metabolic models (GEMs) [6] [7]. This constraint-based approach calculates the flow of metabolites through metabolic networks, enabling researchers to predict an organism's growth rate or the production rate of biotechnologically important metabolites without requiring difficult-to-measure kinetic parameters [6]. FBA has become indispensable in systems biology, metabolic engineering, and drug discovery for interpreting and predicting phenotypic states and the consequences of environmental and genetic perturbations [7] [8]. For E. coli research specifically, FBA provides a computational framework to map metabolic capabilities and understand genotype-phenotype relationships under different conditions [9].

Core Components of an FBA Model

Every FBA model is built upon three fundamental components: the stoichiometric matrix that defines the network topology, constraints that limit system behavior, and objective functions that define biological goals.

The Stoichiometric Matrix (S-Matrix)

The stoichiometric matrix provides the mathematical foundation for metabolic network reconstructions, representing all known metabolic reactions for an organism [7].

Mathematical Representation and Structure The stoichiometric matrix S is an m×n matrix where m represents the number of metabolites and n represents the number of reactions in the network [6]. Each column in the matrix represents a biochemical reaction, while each row corresponds to a unique metabolite. The entries in each column are the stoichiometric coefficients of the metabolites participating in that reaction, with negative coefficients indicating consumed metabolites and positive coefficients indicating produced metabolites [6] [10].

Fundamental Role in Mass Balance The primary role of the stoichiometric matrix is to enforce mass balance constraints on the system through the equation: S · v = 0 where v is the flux vector containing the rates of all reactions in the network [9] [6]. This equation ensures that the total amount of any compound being produced equals the total amount being consumed at steady state, preventing unrealistic accumulation or depletion of internal metabolites [6] [10].

Table 1: Structure and Function of the Stoichiometric Matrix

| Aspect | Description | Biological Significance |

|---|---|---|

| Matrix Dimensions | m rows (metabolites) × n columns (reactions) | Determines network complexity and scope [6] |

| Element Values | Stoichiometric coefficients (negative for substrates, positive for products) | Quantifies metabolite conversion ratios in reactions [6] |

| Core Equation | S · v = 0 | Enforces mass conservation at metabolic steady state [9] [6] |

| Null Space | All flux vectors v satisfying S · v = 0 | Defines all theoretically possible flux distributions [6] [10] |

Figure 1: The stoichiometric matrix forms the foundation of FBA models by connecting metabolites and reactions through mass balance constraints that define the feasible flux space.

System Constraints

Constraints represent the known or imposed limitations of a biological system that restrict the possible flux distributions to physiologically relevant ranges [6].

Mass Balance Constraints As defined by the stoichiometric matrix, mass balance constraints ensure that for each internal metabolite, the combined production and consumption rates balance to zero at steady state [6] [10]. This prevents unrealistic accumulation or depletion of metabolic intermediates during simulations.

Flux Capacity Constraints These constraints define upper and lower bounds on reaction fluxes through the inequality: αi ≤ vi ≤ βi where αi represents the lower bound and βi the upper bound for each reaction i [9]. These bounds incorporate:

- Reversibility Constraints: Irreversible reactions are constrained to have non-negative fluxes (0 ≤ vi ≤ βi) [9]

- Transport Flux Limitations: Nutrient uptake rates are constrained based on environmental availability and transporter capacity [9] [6]

- Thermodynamic Constraints: Based on energy considerations and reaction energetics [9]

Environmental and Genetic Constraints

- Nutrient Availability: When a metabolite is unavailable in the simulated medium, its transport flux is constrained to zero [9]

- Gene Deletion Mutations: Reactions catalyzed by deleted genes are constrained to zero flux [9] [11]

- Regulatory Constraints: Advanced implementations incorporate gene regulatory information to activate or deactivate reactions based on environmental signals [11]

Table 2: Types of Constraints in FBA Models

| Constraint Type | Mathematical Form | Biological Basis | Implementation Example |

|---|---|---|---|

| Mass Balance | S · v = 0 | Law of mass conservation | Applied to all internal metabolites at steady state [6] |

| Reversibility | vi ≥ 0 | Thermodynamics of irreversible reactions | Glycolytic reactions in E. coli [9] |

| Capacity | vi ≤ vi^max | Enzyme abundance and activity | Glucose uptake limited to 18.5 mmol/gDW/hr in E. coli [6] |

| Environmental | vtransport = 0 | Nutrient absence in growth medium | Oxygen uptake set to zero for anaerobic conditions [9] [6] |

| Genetic | vi = 0 | Gene knockout experiments | Deletion of pta or zwf genes in E. coli [9] |

Objective Functions

The objective function defines the biological goal that the metabolic network is presumed to be optimizing, allowing identification of a particular flux distribution within the feasible solution space [6] [8].

Biomass Maximization The most commonly used objective function in microbial FBA is the biomass objective function (BOF), which maximizes the efficiency of biomass production [6] [12]. The biomass reaction converts biosynthetic precursors (amino acids, nucleotides, lipids, carbohydrates) into biomass at stoichiometries representing the organism's composition [9] [12]. The flux through this reaction represents the exponential growth rate (μ) of the organism [6].

Metabolite Production For metabolic engineering applications, objective functions may maximize the production of specific metabolites of biotechnological interest, such as:

- Biofuels and solvents (ethanol, butanol, isopropanol) [8]

- Pharmaceutical precursors

- Industrial enzymes or chemicals

ATP and Energy Objectives Alternative objective functions include maximizing ATP production or minimizing total metabolic flux (representing metabolic efficiency) [6]. The appropriateness of different objective functions depends on the biological context and can be evaluated using experimental data [8] [12].

Objective Function Formulation Mathematically, objective functions are expressed as: Z = c^T · v where c is a vector of weights indicating how much each reaction contributes to the objective [6]. For single-reaction objectives like biomass maximization, c is a vector of zeros with a value of 1 at the position of the reaction of interest [6].

Table 3: Common Objective Functions in FBA of E. coli

| Objective Function | Mathematical Form | Research Context | Performance Indicators |

|---|---|---|---|

| Biomass Maximization | max vbiomass | Simulation of growth under different conditions [6] | Predicts growth rates of 1.65 hr⁻¹ (aerobic) and 0.47 hr⁻¹ (anaerobic) in E. coli [6] |

| Metabolite Production | max vproduct | Metabolic engineering for compound synthesis [8] | High product yield and flux compatibility with growth |

| ATP Maximization | max vATP | Energy metabolism studies [6] | ATP production rate and coupling to substrate utilization |

| Weighted Sum of Fluxes | max Σ cjvj | Multi-objective optimization [8] | Alignment with experimental fluxomics data |

Comparative Analysis of FBA Model Performance

The predictive capability of FBA models depends on the accurate specification of all three core components, with particular sensitivity to objective function selection and biomass composition.

Effect of Biomass Composition on Predictions

The biomass reaction composition significantly influences FBA predictions, as intracellular fluxes adjust to meet biosynthetic demands [12]. Studies on Arabidopsis thaliana models revealed that while central metabolic fluxes remain relatively stable across varying biomass compositions, model structure itself significantly impacts predictions [12]. This highlights the importance of species-specific and condition-specific biomass compositions for accurate FBA simulations.

Objective Function Selection Criteria

Choosing appropriate objective functions remains challenging in FBA. The TIObjFind framework addresses this by integrating Metabolic Pathway Analysis (MPA) with FBA to systematically infer metabolic objectives from experimental data [8]. This approach calculates Coefficients of Importance (CoIs) that quantify each reaction's contribution to objective functions that best align with experimental fluxes [8].

Advances in FBA Integration with Other Modeling Approaches

Recent methodological advances have enhanced FBA's predictive power through integration with complementary approaches:

Machine Learning Integration Machine learning techniques help interpret large-scale flux distributions and identify key regulatory patterns in metabolic networks [13]. These approaches are particularly valuable for analyzing complex multi-omics datasets and predicting metabolic behaviors under untested conditions.

Regulatory Constraints Genetically constrained metabolic flux analysis incorporates gene regulatory networks to dynamically adjust metabolic maps in response to environmental signals [11]. For example, integrating E. coli's oxygen and redox sensing systems (Arc and FNR) improves prediction of aerobic/anaerobic metabolic transitions [11].

Kinetic Modeling Integration Combining FBA with kinetic models enables more comprehensive simulations of dynamic metabolic behaviors, overcoming FBA's steady-state limitations [13].

Experimental Protocols for FBA Validation

Protocol 1: Growth Rate Prediction in E. coli

This protocol outlines the standard FBA workflow for predicting growth rates under different conditions [6] [10].

Computational Methods

- Model Loading: Import the E. coli metabolic model (e.g., core model from the COBRA Toolbox) [6]

- Constraint Definition:

- Objective Selection: Set biomass production as the objective function to maximize

- Linear Programming: Solve the optimization problem using algorithms such as simplex or interior point methods [6] [10]

- Solution Extraction: Extract the growth rate (flux through biomass reaction) and key metabolic fluxes

Validation Metrics Compare predicted growth rates with experimental measurements: approximately 1.65 hr⁻¹ for aerobic growth and 0.47 hr⁻¹ for anaerobic growth on glucose minimal medium [6].

Protocol 2: Gene Essentiality Prediction

This protocol assesses the ability of FBA to predict essential genes in central metabolism [9].

Computational Methods

- Reference Simulation: First compute the wild-type growth rate with the desired medium conditions

- Gene Deletion Simulation: For each gene of interest, constrain all associated metabolic reactions to zero flux [9]

- Growth Calculation: Recompute the maximum biomass production

- Essentiality Classification: Genes whose deletion reduces growth below a threshold (e.g., <5% of wild-type) are classified as essential [9]

Validation Data For E. coli grown aerobically on glucose minimal medium, FBA predicts 7 essential gene products in central metabolism, including genes in glycolysis, PPP, TCA cycle, and electron transport [9]. Under anaerobic conditions, 15 gene products are predicted essential [9].

Figure 2: Standard workflow for Flux Balance Analysis showing the sequential steps from model initialization through constraint definition, problem solution, and results validation.

The Scientist's Toolkit: Research Reagent Solutions

Table 4: Essential Computational Tools for FBA Research

| Tool Name | Platform | Primary Function | Application Context |

|---|---|---|---|

| COBRA Toolbox [6] | MATLAB | Suite of constraint-based reconstruction and analysis methods | Performing FBA and related analyses on genome-scale models |

| COBRApy [7] | Python | Python implementation of COBRA methods | Scriptable, flexible metabolic modeling and analysis |

| KBase [14] [15] | Web-based platform | Integrated FBA solution comparison and model analysis | Comparing multiple FBA solutions and models in a user-friendly environment |

| OptKnock [6] | MATLAB/Python | Identification of gene knockout strategies for strain optimization | Metabolic engineering of E. coli for enhanced product formation |

| TIObjFind [8] | MATLAB | Framework for identifying metabolic objective functions | Determining context-specific objective functions from experimental data |

The three core components of FBA models—stoichiometric matrix, constraints, and objective functions—work in concert to enable quantitative prediction of metabolic behaviors. The stoichiometric matrix defines the network topology, constraints incorporate physiological limitations, and objective functions specify biological goals. For E. coli researchers, selecting appropriate model components requires consideration of biological context, available experimental data, and specific research questions. Advances in integrating FBA with regulatory information, machine learning, and kinetic models continue to enhance its predictive power for both basic research and biotechnological applications. Future developments will likely focus on multi-scale integration and improved handling of metabolic regulation.

Genome-scale metabolic models (GEMs) are computational representations of the biochemical reaction networks within an organism, enabling the simulation of metabolic capabilities using constraints-based methods like Flux Balance Analysis (FBA). For Escherichia coli, a cornerstone organism in microbial research and biotechnology, several GEMs have been developed. The selection of an appropriate model is critical for research and drug development, as it directly impacts the accuracy of phenotypic predictions, from gene essentiality to the production of valuable metabolites. This guide provides a detailed comparison of two prominent E. coli GEMs—iML1515 and iDK1463—framed within the broader thesis of FBA model selection criteria. We objectively compare their performance, supported by experimental data, and introduce iCH360 as an emerging compact model for specific applications.

The iML1515 and iDK1463 models represent different E. coli strains and were built for distinct research purposes, which is reflected in their genomic coverage and core applications.

Table 1: Overview and Genomic Coverage of Featured E. coli GEMs

| Feature | iML1515 | iDK1463 | iCH360 |

|---|---|---|---|

| Represented Strain | E. coli K-12 MG1655 (intestinal commensal) [16] [5] | E. coli Nissle 1917 (Probiotic strain, EcN) [17] [18] | E. coli K-12 MG1655 (Central metabolism) [5] [19] |

| Total Genes | 1,515 [5] | 1,463 [17] | 360 [5] |

| Total Reactions | 2,712 [5] | 2,984 [17] | Not explicitly stated |

| Total Metabolites | 1,877 [5] | 1,313 [17] | Not explicitly stated |

| Primary Application | General-purpose metabolic simulations and gene essentiality studies [16] [5] | Probiotic metabolism, host-microbe interactions, therapeutic design [17] [18] | Core and biosynthetic metabolism analysis, educational tool, advanced modeling methods [5] [19] |

| Key Distinguishing Feature | Considered a gold-standard, highly curated model for a laboratory strain [16] [17] | First comprehensive metabolic model for the probiotic EcN [17] | A compact, "Goldilocks-sized" model enriched with thermodynamic and kinetic data [5] [19] |

Performance Comparison and Experimental Validation

Model performance is typically validated by comparing simulation predictions against empirical data, such as growth phenotypes on different nutrient sources or gene essentiality.

Table 2: Experimental Validation and Performance Metrics

| Model | Validation Experiment | Key Performance Result | Reported Limitations / Error Sources |

|---|---|---|---|

| iML1515 | Comparison to high-throughput mutant fitness data (RB-TnSeq) across 25 carbon sources [16] | Quantified using area under a precision-recall curve; accuracy trends were assessed across model versions [16] | False-negative predictions for vitamin/cofactor biosynthesis genes; inaccuracies from isoenzyme gene-protein-reaction mapping [16] |

| iDK1463 | Phenotype Microarray (PM) tests measuring growth on hundreds of carbon, nitrogen, phosphorus, and sulfur sources [17] | Model was improved and validated by comparing simulation results with experimental PM data [17] | The EcN genome was initially poorly annotated, requiring extensive manual curation during model reconstruction [17] |

| iHM1533 | Phenotype Microarray (PM) tests and comparison with 13C fluxomics data [18] | 82.3% accuracy in predicting growth phenotypes on various nutritional sources [18] | This is an updated model of EcN; the predecessor iDK1463 was used as a base for comparison and import of reactions [18] |

Detailed Experimental Protocols

To ensure reproducibility and provide context for the data in the comparison tables, here are the detailed methodologies for key experiments cited.

Protocol 1: Validating GEMs with High-Throughput Mutant Fitness Data

This protocol, used to validate iML1515, involves quantifying model accuracy by comparing simulations to large-scale experimental fitness data [16].

- Experimental Data Collection: Obtain published fitness data from RB-TnSeq experiments for thousands of gene knockouts across multiple environmental conditions (e.g., 25 different carbon sources) [16].

- In Silico Simulation of Experiments: For each experimental condition (e.g., a specific gene knockout and carbon source):

- Constrain the model's uptake reaction for the specific carbon source.

- Simulate a gene knockout by setting the flux through reactions associated with that gene to zero.

- Use Flux Balance Analysis (FBA) to predict a growth/no-growth phenotype.

- Accuracy Quantification: Compare the model's predictions against the experimental data. Use the area under a precision-recall curve (AUC) as a robust metric, which is particularly suited for imbalanced datasets where correctly predicting gene essentiality (true negatives) is biologically more critical [16].

- Error Analysis: Identify recurring errors (e.g., false negatives) and investigate their biochemical basis, such as the availability of vitamins/cofactors in the experimental medium due to cross-feeding or metabolite carry-over [16].

Protocol 2: Model Validation with Phenotype Microarray (PM) Tests

This protocol, used for validating both iDK1463 and iHM1533, leverages high-throughput growth phenotyping [17] [18].

- Strain Cultivation: Grow the target E. coli strain (e.g., EcN for iDK1463) under a wide array of conditions provided by PM plates. These plates test utilization of hundreds of unique carbon, nitrogen, phosphorus, and sulfur sources, as well as resistance to various inhibitory compounds [17].

- Growth Measurement: Quantify cellular growth (e.g., via turbidity) in each well of the PM plates over time to generate an experimental profile of digestible and inhibitory substrates [17].

- In Silico Simulation of PM Conditions: For each nutrient source tested in the PM experiment:

- Constrain the model's environment to reflect the minimal medium, allowing only the specific nutrient source to be taken up.

- Use FBA to predict the growth rate.

- Apply a growth threshold to predict a binary growth/no-growth outcome.

- Model Curation and Validation: Compare the model's predictions with the experimental PM data. Calculate the percentage of correct predictions. Manually curate the model (e.g., through gap-filling) to resolve discrepancies and improve accuracy [17] [18].

Metabolic Pathway and Workflow Visualizations

The following diagrams illustrate the core metabolic coverage of the iCH360 model and the general workflow for GEM validation.

Diagram 1: iCH360 Model Coverage

Diagram 2: GEM Validation Workflow

The Scientist's Toolkit: Essential Research Reagents and Materials

The following table details key reagents and computational tools used in the development and validation of the GEMs discussed.

Table 3: Key Research Reagents and Computational Tools

| Item Name | Function / Application | Relevance to GEM Development |

|---|---|---|

| Phenotype Microarray (PM) Plates | High-throughput experimental profiling of microbial growth on hundreds of nutrient sources and under stress conditions [17]. | Used as a primary source of experimental data for validating and curating metabolic models like iDK1463 and iHM1533 [17] [18]. |

| RB-TnSeq (Random Barcode Transposon Sequencing) | A method for large-scale parallel fitness assays of gene knockout mutants across diverse environmental conditions [16]. | Provides genome-wide mutant fitness data used to rigorously quantify the prediction accuracy of models like iML1515 [16]. |

| Flux Balance Analysis (FBA) | A constraints-based optimization algorithm used to predict metabolic flux distributions and growth rates in a GEM [20]. | The core simulation method for predicting gene essentiality and substrate utilization in all featured GEMs [16] [17] [5]. |

| EcoCyc Database | A comprehensive bioinformatics database for E. coli biology, detailing its genome, metabolic pathways, and regulatory network [5]. | Serves as a gold-standard knowledgebase for manual curation of E. coli GEMs, ensuring reaction stoichiometry and gene-protein-reaction rules are accurate [5]. |

| AGORA2 (Assembly of Gut Organisms through Reconstruction and Analysis, v2) | A resource containing curated, strain-level GEMs for over 7,300 human gut microbes [21]. | Used in a bottom-up approach to screen for and model interactions of probiotic LBP candidates with resident gut microbiota [21]. |

Selecting the appropriate E. coli GEM is a critical decision that hinges on the specific research question and organism strain. The general-purpose iML1515 model offers a extensively validated framework for the K-12 strain, ideal for fundamental studies in metabolism and gene essentiality. In contrast, the iDK1463 and its successor iHM1533 are indispensable for research focused on the probiotic E. coli Nissle 1917, particularly for investigating host-microbe interactions and developing live biotherapeutic products. For projects requiring deep, curated analysis of central metabolism or the application of advanced modeling techniques like elementary flux mode analysis, the compact iCH360 model presents a powerful "Goldilocks" alternative. Ultimately, the choice of model should be guided by the criteria of strain representation, model scope, and the strength of its experimental validation for the intended application.

Defining the Biomass Objective Function and Its Critical Role in Growth Predictions

Table of Contents

- Introduction to the Biomass Objective Function

- Formulating a BOF: Components and Levels of Detail

- Computational Tools for BOF Construction

- Experimental Validation of BOF Accuracy

- The Impact of an Accurate BOF on Model Predictions

Flux Balance Analysis (FBA) has become a cornerstone mathematical approach for analyzing the flow of metabolites through a metabolic network, enabling researchers to predict cellular behavior such as growth rates or the production of key metabolites [22]. At the heart of any FBA simulation aiming to predict growth lies the Biomass Objective Function (BOF). The BOF is a mathematical representation that quantitatively describes the cellular biomass composition, defining the rate and, critically, the precise proportions in which all essential biomass precursors must be synthesized for a cell to double [22] [23]. In essence, it acts as the "recipe" for making a new cell, and simulating growth involves maximizing the output of this biomass reaction. The accuracy of this recipe is paramount; it directly determines the reliability of model predictions for growth, gene essentiality, and nutrient utilization, which are critical for applications in metabolic engineering and drug development [22] [24].

Formulating a BOF: Components and Levels of Detail

The formulation of a biologically realistic BOF is a multi-step process that can be approached at different levels of detail, depending on the available data and the required predictive precision [22].

Level 1: Basic Macromolecular Composition: The process begins with defining the cell's macromolecular makeup—the weight fractions of protein, RNA, DNA, lipids, and carbohydrates [22] [24]. Each category is then broken down into its metabolic building blocks (e.g., amino acids for proteins, nucleotides for RNA and DNA). This defines the core stoichiometric coefficients of the BOF, ensuring the major carbon and nitrogen sinks are accurately represented.

Level 2: Incorporating Polymerization Costs: An intermediate level of detail adds the biosynthetic energy required to polymerize these building blocks. This includes accounting for the consumption of energy molecules like ATP and GTP to drive processes like protein synthesis and RNA transcription, which are part of the cell's maintenance energy requirements [22]. This step also accounts for the by-products of these reactions, such as water and diphosphate.

Level 3: Advanced Cofactors and Species-Specific Metabolites: An advanced BOF includes vital coenzymes, inorganic ions, and species-specific metabolites such as cell wall components (e.g., peptidoglycan in bacteria) [22] [24]. A key concept here is the distinction between a "wild-type" biomass composition, derived from measurements of healthy cells, and a "core" biomass composition. The core BOF represents the minimal set of components required for survival and is often more accurate for predicting gene essentiality, as it avoids falsely predicting that a gene is essential simply because it produces a metabolite that is in the wild-type biomass but not strictly necessary for growth [22] [25].

The following diagram illustrates the workflow and key inputs for building a comprehensive Biomass Objective Function.

Computational Tools for BOF Construction

Constructing a BOF manually is a complex and time-consuming endeavor. Fortunately, computational tools have been developed to standardize and streamline this process using experimental data. The most comprehensive tool currently available is BOFdat, a Python package designed to generate species-specific BOFs in a data-driven, unbiased fashion [24] [26].

BOFdat modularizes the BOF definition process into three distinct steps that align with the levels of detail previously described:

- Step 1 - Macromolecules: Calculates the stoichiometric coefficients for DNA, RNA, proteins, and lipids from experimental macromolecular weight fractions and other omics data (e.g., genomic, proteomic, lipidomic data) [24].

- Step 2 - Cofactors and Ions: Identifies and estimates coefficients for necessary coenzymes and inorganic ions based on the weight fraction of the soluble pool [24].

- Step 3 - Species-Specific Metabolites: Employs a genetic algorithm and experimental gene essentiality data to algorithmically identify the remaining condition-specific and species-specific metabolic biomass precursors, thereby optimizing the model's gene essentiality prediction accuracy [24].

The application of BOFdat to reconstruct the BOF for the gold-standard E. coli model iML1515 resulted in superior concordance with experimental biomass composition, growth rate, and gene essentiality predictions compared to other methods [24]. This highlights the power of using systematic, data-driven workflows over ad-hoc or phylogeny-based approaches.

Experimental Validation of BOF Accuracy

Once a BOF is integrated into a Genome-Scale Metabolic (GEM) model, its accuracy must be rigorously validated against experimental data. For E. coli models, which are benchmarks in the field, validation typically involves several types of phenotypic comparisons [16] [25].

Table 1: Key Metrics for Validating E. coli GEM Predictions

| Validation Metric | Description | What It Tests | Limitations |

|---|---|---|---|

| Gene Essentiality [16] [25] | Comparing predicted growth/no-growth of gene knockouts with experimental mutant fitness data. | Accuracy of the BOF and network in identifying necessary metabolic pathways. | Can be confounded by cross-feeding or metabolite carry-over in high-throughput experiments [16]. |

| Nutrient Utilization [25] | Predicting growth or lack thereof on different sole carbon/nitrogen sources. | Comprehensive functional capability of the metabolic network and its constraints. | A qualitative (yes/no) test; does not validate growth rates or internal flux distributions. |

| Quantitative Growth Rates [27] | Comparing simulated growth yields or rates with experimental measurements in chemostat or batch culture. | Consistency of biomass composition and maintenance energy requirements with observed metabolic efficiency. | Does not validate the accuracy of predicted internal flux distributions. |

Recent large-scale validation studies using high-throughput mutant fitness data have revealed specific areas where BOF and model accuracy can be improved. For instance, in the iML1515 model, many false-negative predictions (where a gene is incorrectly predicted to be essential) occur in the biosynthetic pathways for vitamins and cofactors like biotin, thiamin, and NAD+ [16]. This often points to an issue where these metabolites are available to mutants in the experiment (via cross-feeding or carry-over from pre-cultures) but are not provided in the in silico simulation medium, rather than a fundamental error in the BOF itself [16]. This underscores the importance of carefully aligning simulation constraints with real experimental conditions when validating a model.

The Impact of an Accurate BOF on Model Predictions

The quantitative definition of the BOF has a profound impact on model behavior and the reliability of its predictions for downstream applications [28] [24]. A well-validated BOF is crucial for:

Predicting Gene Essentiality: Gene essentiality in FBA is principally determined by the biomass demands. If a metabolite is included in the BOF, the genes required to synthesize it become essential for growth in the corresponding minimal media [25]. Using a refined "core" biomass can significantly improve essentiality prediction accuracy [22] [25]. For example, the EcoCyc-18.0-GEM, which paid close attention to its BOF, achieved a 95.2% accuracy in predicting gene knockout phenotypes, a 46% reduction in error rate compared to a previous model [25].

Informing Evolutionary Studies: FBA is an evolutionary optimality model that assumes metabolism is tuned to maximize fitness. The BOF defines this optimality criterion (typically biomass yield). Research shows that FBA's predictive power for metabolic evolution depends on the starting strain's optimality. Strains initially far from the predicted optimum often evolve toward the FBA-predicted state, whereas those already near the optimum may evolve in other directions, for instance, favoring substrate uptake rate over yield [28].

Enabling Metabolic Engineering: In biomanufacturing, the BOF can be modified to redirect flux from biomass to a desired product. An accurate baseline BOF is essential to reliably simulate these metabolic interventions and predict titer, yield, and productivity [22].

Research Reagent Solutions

Table 2: Essential Reagents and Resources for BOF-Driven Research

| Reagent / Resource | Function in BOF Research |

|---|---|

| BOFdat Software [24] [26] | A Python package for the data-driven generation of species-specific Biomass Objective Functions from experimental data. |

| E. coli GEM (iML1515) [16] [24] | A gold-standard, community-curated genome-scale metabolic model of E. coli K-12 MG1655 used for benchmarking and method development. |

| RB-TnSeq Mutant Fitness Data [16] | High-throughput gene essentiality dataset used for the validation and refinement of GEMs and their BOFs. |

| MEMOTE Test Suite [27] | A software suite for standardized quality control and testing of genome-scale metabolic models, ensuring basic biochemical and genetic consistency. |

| 13C-Labeling Data (for MFA) [28] [27] | Experimental data from isotopic tracer experiments used to validate internal metabolic flux predictions, providing a strong test of model (and BOF) accuracy. |

A critical step in harnessing Flux Balance Analysis (FBA) for E. coli research is the accurate definition of its simulated cultivation environment. The predictive power of a genome-scale metabolic model (GEM) is wholly dependent on the constraints applied, which represent the organism's physicochemical conditions [27]. This guide compares common approaches for setting up this in silico environment, evaluating their performance based on validation against experimental data.

Comparative Analysis of Environmental Constraints in FBA

The formulation of an FBA problem for E. coli involves defining a stoichiometric matrix (S) and constraining the flux vector (v) with lower and upper bounds (lb, ub) to represent the simulation environment. A generic FBA problem is structured as shown in Table 1.

Table 1: Core Components of an FBA Problem Formulation

| Component | Mathematical Symbol | Description | Role in Simulating the Environment |

|---|---|---|---|

| Stoichiometric Matrix | S | An m x n matrix where m is the number of metabolites and n is the number of reactions. | Encodes the network structure of the metabolism. |

| Flux Vector | v | A vector of reaction fluxes (mmol/gDW/h). | Represents the metabolic state to be solved for. |

| Lower/Upper Bounds | lb, ub | Vectors defining the minimum and maximum allowable flux for each reaction. | Directly encodes environmental constraints:- Substrate uptake rates.- Oxygen availability.- Byproduct secretion. |

| Objective Function | c | A vector of coefficients selecting the flux to be optimized (e.g., biomass). | Defines the cellular goal (e.g., growth maximization). |

The bounds on exchange reactions for metabolites are the primary levers for simulating different environments. Table 2 compares the performance of different E. coli GEMs when validated against high-throughput mutant fitness data, highlighting the impact of model curation, which includes environmental definition.

Table 2: Accuracy Comparison of E. coli GEMs for Predicting Gene Essentiality [16]

| Model Version | Year | Genes in Model | Precision-Recall AUC (Initial) | Key Environmental Factors Impacting Accuracy |

|---|---|---|---|---|

| iJR904 | 2003 | ~904 | 0.30 | Early models lacked comprehensive cofactor and vitamin definitions. |

| iAF1260 | 2007 | ~1,260 | 0.25 | |

| iJO1366 | 2011 | ~1,366 | 0.22 | Decreasing initial accuracy was partly attributed to incorrect representation of the experimental environment in simulations. |

| iML1515 | 2017 | ~1,515 | 0.20 | |

| iML1515 (Corrected) | - | ~1,515 | ~0.35 (Estimated from fig) | Accuracy improved significantly by adding specific vitamins/cofactors (Biotin, R-pantothenate) to the simulation medium, correcting for in vitro cross-feeding or carry-over [16]. |

Experimental Protocols for Validating Simulated Environments

This protocol tests the model's ability to accurately predict growth on different primary carbon sources, a direct test of the medium composition setup.

- Objective: To validate FBA predictions of growth/no-growth phenotypes under defined environmental conditions.

- Experimental Workflow:

- In silico Simulation: Set up the model environment with a single carbon source (e.g., 10 mmol/gDW/h glucose) and a defined oxygen uptake rate (e.g., 15-20 mmol/gDW/h for aerobic, 0 for anaerobic). Simulate growth using FBA with biomass maximization as the objective.

- In vitro Cultivation: Grow E. coli strains in MOPS minimal media with the same carbon source.

- Condition Control: For anaerobic conditions, incubate cultures in sealed bags saturated with a 95% N₂ and 5% CO₂ gas mixture, confirmed using an obligate aerobic control [29].

- Phenotype Measurement: Measure growth rates or use colorimetric assays in pre-configured plates (e.g., Biolog PM1 plates) to determine substrate utilization [29].

- Validation: Compare the in silico predicted growth phenotype (growth/no-growth) and, if available, growth rate with the experimental observation.

The following diagram illustrates the workflow for this validation protocol.

Workflow for Carbon Source Validation

This protocol addresses a common source of error where simulated environments inaccurately represent the true availability of essential metabolites, leading to false predictions of gene essentiality.

- Objective: To identify and correct for the presence of trace vitamins/cofactors in the experimental environment that are not included in the defined in silico medium.

- Methodology:

- Error Identification: Run a genome-wide in silico gene knockout screen using a defined minimal medium. Identify genes whose knockout leads to a predicted growth defect (false negative).

- Pathway Analysis: Cluster these false-negative genes. They often belong to biosynthetic pathways for specific vitamins/cofactors (e.g., Biotin, Tetrahydrofolate, NAD+) [16].

- Hypothesis Testing: In the model, add the identified vitamin/cofactor to the simulation environment's medium composition.

- Validation: Re-run the essentiality predictions. A significant improvement in model accuracy (e.g., increase in Precision-Recall AUC) confirms the hypothesis that these metabolites were available in the physical experiment, likely via cross-feeding between mutants or carry-over from pre-cultures [16].

The Scientist's Toolkit: Essential Reagents and Models

Table 3: Key Reagents and Computational Tools for E. coli FBA

| Item Name | Function/Description | Example Use in FBA Context |

|---|---|---|

| MOPS Minimal Medium | A defined, chemically synthesized medium that allows precise control over nutrient availability. | Serves as the basis for in vitro experiments to validate in silico predictions under controlled conditions [29]. |

| Biolog PM Plates | Pre-configured microplates containing different carbon or nitrogen sources. | Enable high-throughput experimental phenotyping for model validation across dozens of environmental conditions [29]. |

| E. coli K-12 MG1655 GEM (iML1515) | The most recent, community-vetted genome-scale metabolic model for the standard E. coli K-12 strain. | The primary in silico tool for simulation; its accurate use requires proper environmental constraint setup [16]. |

| EColiCore2 Model | A reduced, high-quality model of E. coli central metabolism derived from the genome-scale model iJO1366. | Ideal for computational techniques that are infeasible with larger models, such as exhaustive elementary-modes analysis [30]. |

| COBRA Toolbox / cobrapy | Software suites for constraint-based reconstruction and analysis. | Provide the core computational functions to implement FBA, define medium constraints, and simulate gene knockouts [27]. |

Logical Workflow for Defining the Simulation Environment

The process of setting up a robust simulation environment is iterative. The following diagram outlines a logical pathway for researchers, integrating decisions on medium composition and physicochemical parameters, and highlighting key validation checkpoints.

Environment Setup and Validation Logic

Implementing FBA Models for Predictive Simulation and Discovery

Flux Balance Analysis (FBA) represents a cornerstone mathematical approach for simulating cellular metabolism at the genome scale, enabling researchers to predict metabolic flux distributions without requiring detailed enzyme kinetic parameters [31]. This constraint-based modeling technique relies on genome-scale metabolic network reconstructions that describe all known biochemical reactions within an organism and the genes encoding them [31]. For Escherichia coli K-12 MG1655—one of the most well-established model organisms for metabolic studies—FBA has played a pivotal role in everything from metabolic engineering to drug target identification [16] [25]. The COnstraint-Based Reconstruction and Analysis (COBRA) methodology provides the theoretical foundation for these approaches, with COBRApy emerging as a primary Python implementation for performing FBA and related analyses [32] [31].

The accuracy of FBA predictions, however, depends critically on appropriate model selection and a rigorous computational workflow. This guide provides a comprehensive step-by-step protocol for implementing FBA using COBRApy, framed within the context of E. coli metabolic network research. We objectively compare model performance across different E. coli genome-scale metabolic models (GEMs) and provide experimental validation data to assist researchers, scientists, and drug development professionals in selecting optimal models for their specific applications.

Comparative Analysis of E. coli Metabolic Models

Evolution and Performance Metrics of E. coli GEMs

The development of E. coli metabolic models has progressed significantly over two decades of iterative curation. Understanding the capabilities and validation status of available models is essential for appropriate model selection.

Table 1: Comparison of E. coli Genome-Scale Metabolic Models

| Model Name | Publication Year | Genes | Reactions | Metabolites | Key Features and Applications |

|---|---|---|---|---|---|

| iJR904 | 2003 | 904 | Not specified in search results | Not specified in search results | Early foundational model [16] |

| iAF1260 | 2007 | Not specified in search results | Not specified in search results | Not specified in search results | Expansion of network coverage [16] |

| iJO1366 | 2011 | 1,366 | Not specified in search results | Not specified in search results | Major community reference model [16] [25] |

| iML1515 | 2017 | 1,515 | Not specified in search results | Not specified in results | Incorporates additional metabolites and genes; latest in Palsson series [16] |

| EcoCyc-18.0-GEM | 2014 | 1,445 | 2,286 | 1,453 | Automatically generated from EcoCyc database; updated multiple times yearly [25] |

| iDK1463 | Not specified | 1,463 | 2,984 | Not specified in results | Artificially refined, high-quality GEM validated by MEMOTE [31] |

Performance validation studies have revealed important insights into model accuracy. When comparing four subsequent E. coli GEMs using published mutant fitness data across thousands of genes and 25 different carbon sources, the area under a precision-recall curve (AUC) served as a robust accuracy metric [16]. Initial calculations surprisingly showed that accuracy steadily decreased from iJR904 to iML1515, though this trend was later reversed by correcting the analysis approach to account for vitamin and cofactor availability in experimental conditions [16]. The EcoCyc-18.0-GEM demonstrated notable performance, with an error rate in predicting gene-knockout phenotypes that decreased by 46% over the best previous model and an accuracy of 80.7% in predicting growth under 431 different nutrient conditions [25].

Essential Considerations for Model Selection

Model selection must account for several critical factors:

- Vitamin and Cofactor Biosynthesis: Many genes involved in biosynthetic pathways for biotin, R-pantothenate, thiamin, tetrahydrofolate, and NAD+ cause false-negative predictions in iML1515, as these compounds may be available to mutants in experimental conditions despite being absent from defined growth media [16].

- Gene-Protein-Reaction Mapping: Isoenzyme mapping has been identified as a key source of inaccurate predictions, necessitating careful attention to reaction annotations [16].

- Update Frequency: Models like EcoCyc-18.0-GEM, which are automatically generated from continuously updated databases, offer advantages in incorporating the latest biochemical knowledge [25].

- Experimental Context: Cross-feeding between mutants or metabolite carry-over can significantly impact model validation, particularly in high-throughput mutant phenotyping experiments [16].

Step-by-Step FBA Workflow with COBRApy

Model Loading and Initialization

The foundation of any FBA analysis begins with loading an appropriate metabolic model. COBRApy supports multiple model formats, with SBML (Systems Biology Markup Language) being the standard.

The "textbook" model refers to a core E. coli metabolic model that is frequently used for demonstration purposes [32]. For research applications, researchers should select from the validated genome-scale models discussed in Section 2. The iML1515 model represents the latest comprehensive model for E. coli K-12 MG1655, while iDK1463 has been used in specialized applications such as engineering L-DOPA production [16] [31].

Model Configuration and Objective Setting

FBA requires definition of an objective function that the model will optimize, typically biomass production representing cellular growth.

Most E. coli GEMs utilize a biomass reaction that represents the biomolecular composition of the cell as the default objective function [25]. However, researchers can customize this objective to simulate different biological scenarios, such as maximizing production of specific metabolites [32].

Medium Definition and Environmental Constraints

Defining the extracellular environment is crucial for accurate simulation. This involves setting appropriate exchange reaction bounds to reflect nutrient availability.

Table 2: Typical Minimal Medium Composition for E. coli FBA Simulations

| Component | Exchange Reaction | Typical Concentration (mM) | Notes |

|---|---|---|---|

| Glucose | EXglcDe | 10-20 | Primary carbon source [32] [31] |

| Ammonium | EXnh4e | 40 | Nitrogen source [31] |

| Phosphate | EXpie | 2 | Phosphorus source [31] |

| Oxygen | EXo2e | 20 | Electron acceptor for aerobic conditions [32] |

| Water | EXh2oe | Unconstrained | Typically unlimited [32] |

The composition should reflect the experimental conditions being simulated. For gut microbiome simulations, different carbon sources such as α-ketoglutarate, lactate, malate, and succinate may be more appropriate [33].

Model Optimization and Solution Analysis

With the model configured, FBA can be performed to obtain an optimal flux distribution.

The model.optimize() function returns a Solution object containing the objective value, status from the linear programming solver, flux distributions, and shadow prices [32]. For repeated optimizations where only the objective value is needed, model.slim_optimize() provides better performance as it avoids the overhead of collecting all flux values [32].

Results Interpretation and Visualization

COBRApy provides multiple methods for interpreting and visualizing FBA results.

The summary methods provide input-output behavior of the model or specific metabolites, displaying information on producing and consuming reactions along with their flux percentages [32]. For mapping flux distributions to pathway maps, tools like Escher can be used, though researchers should note that discrepancies have been reported between solution fluxes and model summary fluxes in some instances [34].

Advanced FBA Techniques and Experimental Validation

Flux Variability Analysis (FVA)

FBA typically returns a single optimal solution, but multiple flux states may achieve the same optimum. Flux Variability Analysis (FVA) addresses this by determining the range of possible fluxes for each reaction while maintaining the optimal objective value.

FVA is particularly valuable for identifying alternative flux states and understanding network flexibility [32].

Dynamic FBA (dFBA)

For simulating time-dependent metabolic changes, Dynamic FBA extends standard FBA by incorporating extracellular metabolite kinetics.

dFBA operates iteratively, coupling FBA's steady-state optimization with kinetic models to predict time-dependent changes in metabolite concentrations, cell growth, and environmental influences [31]. This approach is particularly valuable for simulating microbial communities, capturing nutrient competition, cross-feeding, and population dynamics [31].

Experimental Validation of FBA Predictions

Validating FBA predictions against experimental data is essential for establishing model credibility. A 2023 study evaluated E. coli GEM accuracy using high-throughput mutant phenotype data, revealing several important considerations:

- Precision-Recall Metrics: The area under a precision-recall curve (AUC) provides a robust accuracy metric for essential gene prediction, particularly given the imbalanced nature of knockout datasets [16].

- Vitamin/Cofactor Availability: Correcting for available vitamins and cofactors in experimental conditions significantly improved model accuracy, highlighting the importance of accurately representing the simulation environment [16].

- Generation Effects: The number of experimental generations impacts essentiality calls, with some vitamin auxotrophs showing weak negative fitness after five generations but strong negative fitness after twelve generations [16].

Table 3: Common Discrepancies Between FBA Predictions and Experimental Data

| Discrepancy Type | Examples | Potential Causes | Resolution Approaches |

|---|---|---|---|

| False negatives for vitamin/cofactor genes | biotin, R-pantothenate, thiamin, tetrahydrofolate, NAD+ biosynthetic pathways | Cross-feeding between mutants; metabolite carry-over | Add relevant vitamins to simulation medium; increase generation count in validation [16] |

| Incorrect nutrient utilization predictions | 83 incorrect predictions in EcoCyc-18.0-GEM | Gaps in catabolic pathways; regulatory constraints | Manual curation of pathway gaps; integration of regulatory information [25] |

| Partial rather than complete growth recovery | Δtpi and Δppc in glucose | Suboptimal metabolic adjustments in knockout strains | Alternative objective functions; implementation of regulatory constraints [33] |

Table 4: Key Research Reagent Solutions for E. coli FBA Studies

| Resource Type | Specific Examples | Function and Application | Availability |

|---|---|---|---|

| E. coli GEMs | iML1515, iJO1366, EcoCyc-18.0-GEM, iDK1463 | Genome-scale metabolic networks for FBA simulation | BiGG Models Database, EcoCyc, GitHub repositories |

| Software Tools | COBRApy, Pathway Tools, OptFlux | FBA implementation, simulation, and analysis | Open-source platforms |

| Experimental Validation Data | RB-TnSeq mutant fitness data [16] | Model validation and refinement | Published datasets |

| Visualization Tools | Escher, CytoScape, pySankey | Flux visualization and network analysis | Open-source packages |

| Curated Databases | EcoCyc [25], BiGG, KEGG | Biochemical pathway information and reaction stoichiometries | Web access with downloadable content |

Workflow Visualization

The following diagram illustrates the comprehensive FBA workflow from model selection to validation:

A robust FBA workflow using COBRApy encompasses careful model selection, appropriate configuration of environmental conditions, thorough solution analysis, and experimental validation. For E. coli metabolic studies, researchers must consider the trade-offs between model comprehensiveness, computational efficiency, and predictive accuracy when selecting from available genome-scale models. The integration of machine learning approaches with traditional FBA, such as the FlowGAT framework which combines graph neural networks with FBA solutions, represents a promising direction for improving essentiality predictions [35]. Similarly, frameworks like TIObjFind that identify context-specific objective functions through Coefficients of Importance may enhance prediction accuracy under varying environmental conditions [2]. As E. coli metabolic models continue to evolve through iterative curation and validation against expanding experimental datasets, FBA remains an indispensable tool for probing microbial metabolism in silico, with profound implications for biotechnology, biomedical research, and fundamental biological discovery.

Applying FBA for Gene Essentiality Analysis and Drug Target Identification

Flux Balance Analysis (FBA) has emerged as a cornerstone computational method in systems biology for predicting metabolic phenotypes from genome-scale metabolic models (GEMs). This constraint-based approach leverages stoichiometric models of metabolic networks to calculate optimal flux distributions that maximize a specific cellular objective, typically biomass production representing growth [36]. For model organisms such as Escherichia coli, FBA has been widely employed to predict gene essentiality—identifying genes whose deletion impairs cellular survival—which provides crucial insights for drug discovery and metabolic engineering [35] [36].

The fundamental principle behind FBA-based gene essentiality analysis involves simulating gene knockout mutants and comparing their predicted growth rates to wild-type strains. When the deletion of a gene results in a computationally predicted growth defect, that gene is classified as essential [37]. This approach has proven particularly valuable for identifying potential antimicrobial drug targets, as essential genes in pathogens represent promising candidates for therapeutic intervention [38] [36]. However, the accuracy of these predictions depends heavily on multiple factors, including the quality of the metabolic reconstruction, appropriate definition of biomass objectives, and the assumption that deletion strains optimize the same fitness objective as wild-type cells [35] [16].

Recent advances have integrated machine learning with traditional FBA approaches to overcome these limitations, yielding hybrid models that enhance predictive accuracy by leveraging both mechanistic insights and pattern recognition capabilities [35] [39]. This guide provides a comprehensive comparison of current FBA methodologies for gene essentiality analysis and drug target identification, with a specific focus on E. coli metabolic networks, to inform researchers' model selection decisions.

Core FBA Framework

The foundational FBA methodology formulates metabolic flux prediction as a linear programming problem based on the stoichiometric matrix S of the metabolic network. Under steady-state assumptions, the mass balance equation is represented as Sv = 0, where v is the vector of reaction fluxes. Constraints are applied to individual fluxes as vmin ≤ vi ≤ vmax, with irreversible reactions having vmin set to 0 [36]. The optimization problem typically maximizes biomass production (vbiomass), which encapsulates the metabolic requirements for cellular growth:

Maximize vbiomass Subject to Sv = 0 vmin ≤ vi ≤ vmax ∀i [36]

For gene essentiality analysis, this framework is applied to both wild-type and gene deletion strains. The latter is simulated by constraining fluxes through reactions catalyzed by the deleted gene to zero. A gene is predicted as essential if the maximum biomass production rate drops below a specified threshold (often 1-5% of wild-type growth) in the knockout simulation [37].

Advanced Computational Frameworks

Hybrid FBA-Machine Learning Approaches

FlowGAT represents a recent hybrid methodology that integrates FBA with graph neural networks (GNNs). This approach converts FBA-predicted flux distributions into Mass Flow Graphs (MFGs) where nodes represent enzymatic reactions and edges represent metabolite mass flow between reactions. The GNN with attention mechanism then learns to predict gene essentiality directly from wild-type metabolic phenotypes without assuming optimality of deletion strains [35]. This addresses a key limitation of traditional FBA, which presumes both wild-type and knockout strains optimize the same objective, despite evidence that deletion mutants may employ suboptimal survival strategies [35].

NEXT-FBA (Neural-net EXtracellular Trained Flux Balance Analysis) constitutes another hybrid approach that uses artificial neural networks trained on exometabolomic data to derive biologically relevant constraints for intracellular fluxes in GEMs. By capturing relationships between extracellular metabolomics and cellular metabolism, NEXT-FBA predicts bounds for intracellular reaction fluxes that improve the accuracy of essentiality predictions [3].

Two-Stage FBA for Drug Target Identification

The two-stage FBA approach specifically designed for drug target identification consists of two sequential linear programming models. The first identifies optimal fluxes in the pathologic state, while the second determines fluxes in the medication state with minimal side effects. Drug targets are identified by comparing reaction fluxes between both states and examining significant changes [38]. This method incorporates a quantitative definition of damage reflecting side effects—specifically, the deviation of mass flow of non-disease-causing metabolites from their healthy ranges [38].

Topology-Based Machine Learning Models

An alternative structure-first approach abandons flux simulation entirely in favor of topological analysis. This method constructs reaction-reaction graphs from metabolic models and engineers graph-theoretic features (betweenness centrality, PageRank) to describe each gene's topological role. A machine learning classifier (e.g., Random Forest) is then trained on these features to predict essentiality, demonstrating that network architecture itself contains predictive signals for gene essentiality [39].

The diagram below illustrates the key methodological pathways for FBA-based gene essentiality analysis:

Comparative Performance Analysis

Quantitative Assessment of Prediction Accuracy

Extensive validation studies have quantified the performance of various FBA approaches for gene essentiality prediction in E. coli. The table below summarizes key performance metrics across different methodologies:

Table 1: Performance Comparison of FBA Approaches for E. coli Gene Essentiality Prediction

| Method | Model/System | Accuracy Metric | Performance | Reference/Validation |

|---|---|---|---|---|

| Traditional FBA | iML1515 GEM | Precision-Recall AUC | Variable across conditions | [16] |

| Traditional FBA | EcoCyc-18.0-GEM | Gene Essentiality Prediction Accuracy | 95.2% | [25] |

| FlowGAT | E. coli metabolic network | Prediction Accuracy | Close to FBA gold standard across growth conditions | [35] |

| Topology-Based ML | ecolicore model | F1-Score | 0.400 (Precision: 0.412, Recall: 0.389) | [39] |

| Traditional FBA Baseline | ecolicore model | F1-Score | 0.000 | [39] |

Recent evaluation of E. coli GEM accuracy using high-throughput mutant fitness data across 25 different carbon sources revealed that prediction performance varies substantially across conditions and model versions [16]. The progression of E. coli GEMs from iJR904 to iML1515 has shown increasing gene coverage but mixed accuracy trends, highlighting the complex relationship between model comprehensiveness and predictive performance [16].

The EcoCyc-18.0-GEM model, automatically generated from the EcoCyc database using MetaFlux software, demonstrates the current state-of-the-art in traditional FBA, encompassing 1445 genes, 2286 unique metabolic reactions, and 1453 unique metabolites while achieving 95.2% accuracy in predicting growth phenotypes of experimental gene knockouts [25].

Experimental Validation Protocols

Model Training and Validation Workflow

The experimental protocol for developing and validating FBA-based essentiality predictions typically follows a structured workflow:

Model Reconstruction/Selection: Curate or select an appropriate genome-scale metabolic model for the target organism (e.g., iML1515 for E. coli) [16] [25].

Constraint Definition: Define environmental constraints (carbon sources, nutrient availability) and biochemical constraints (reaction reversibility, enzyme capacity) [36].

Simulation: Perform FBA simulations for single-gene deletion mutants by constraining fluxes through target reactions to zero.

Essentiality Classification: Classify genes as essential if the predicted growth rate falls below a threshold (typically 1-5% of wild-type growth).

Validation: Compare predictions against experimental essentiality data from knockout fitness assays (e.g., RB-TnSeq data) [16].

For hybrid machine learning approaches like FlowGAT, additional steps include:

Graph Construction: Convert FBA solutions to Mass Flow Graphs where nodes represent reactions and edges represent metabolite flows between reactions [35].

Node Featurization: Calculate flow-based features for each node using the formula:

Flowi→j(Xk) = Flow+Ri(Xk) × [Flow−Rj(Xk) / Σℓ∈Ck Flow−Rℓ(Xk)]

where Flow+Ri(Xk) and Flow−Rj(Xk) represent production and consumption flows of metabolite Xk by reactions i and j, respectively [35].

Model Training: Train graph neural network with attention mechanism on labeled knock-out fitness data.

Prediction: Use trained model to predict essentiality directly from wild-type metabolic phenotypes.

Validation studies have identified several key sources of inaccuracy in FBA-based essentiality predictions:

Vitamin/cofactor availability: False essentiality predictions for genes involved in biotin, R-pantothenate, thiamin, tetrahydrofolate, and NAD+ biosynthesis resulted from unavailable vitamins/cofactors in simulation environments that were actually available in experiments through cross-feeding or carry-over effects [16].

Isoenzyme mapping: Incorrect gene-protein-reaction mappings lead to inaccurate essentiality predictions, as alternative catalytic routes may compensate for gene deletions [16].

Biomass reaction formulation: Incorrect biomass composition specifications generate false essentiality predictions in biosynthetic pathways [25] [37].

Regulatory constraints: Lack of incorporation of regulatory information leads to incorrect flux predictions in certain conditions [36].

The following workflow diagram illustrates the experimental validation process for FBA models:

Application to Drug Target Identification

Target Identification in Pathogenic Organisms

FBA-based gene essentiality analysis has proven particularly valuable for identifying drug targets in pathogenic organisms. The essential genes predicted by metabolic network analysis represent critical components for pathogen survival, making them promising candidates for therapeutic intervention [36]. Successful applications include:

Mycobacterium tuberculosis: FBA identified proteins essential for mycolic acid synthesis as anti-tubercular drug targets [36].

Plasmodium falciparum: Genome-scale metabolic modeling predicted 40 essential genes as enzymatic drug targets for malaria treatment [36] [38].

Hyperuricemia treatment: Two-stage FBA correctly identified known drug targets for hyperuricemia in purine metabolic pathways while accounting for side effects [38].

The two-stage FBA approach for drug target identification offers particular advantages for therapeutic development by explicitly modeling both efficacy and safety considerations. This method minimizes side effects by quantifying damage as the deviation of mass flow of non-disease-causing metabolites from their healthy ranges [38].

Considerations for Cancer Therapeutics

In cancer research, FBA-based gene essentiality analysis faces unique challenges. Context-specific metabolic networks reconstructed using gene expression data from cancer cell lines have been employed to identify cancer-specific metabolic dependencies [37]. However, studies comparing FBA predictions with high-throughput gene silencing data (e.g., Project Achilles) have revealed conflicting results, highlighting the strong influence of biomass reaction definition on prediction outcomes [37].

Despite these challenges, FBA-based approaches have successfully identified relevant targets in Glioblastoma Multiforme and Non-Small Cell Lung Cancer cell lines, demonstrating the potential for computational metabolic modeling to guide cancer therapy development [37].

Research Reagent Solutions

Table 2: Essential Research Resources for FBA-Based Gene Essentiality Studies

| Resource Type | Specific Examples | Function/Purpose | Key Features |

|---|---|---|---|

| Metabolic Models | iML1515 [16], EcoCyc-18.0-GEM [25], ecolicore [39] | Reference metabolic networks for simulation | Genome-scale coverage, organism-specific curation |

| Software Tools | MetaFlux [25], NEXT-FBA [3], TIObjFind [2] | Constraint-based modeling and analysis | Automation, integration with databases |

| Experimental Data | RB-TnSeq mutant fitness data [16], CCLE gene expression [37] | Model validation and context-specific constraints | High-throughput phenotypic screening |

| Computational Frameworks | FlowGAT [35], ObjFind [2] | Hybrid FBA-machine learning analysis | Graph neural networks, attention mechanisms |

| Biochemical Databases | EcoCyc [25], KEGG [2] | Reaction stoichiometry and pathway information | Curation quality, update frequency |

The comparative analysis of FBA methodologies for gene essentiality analysis reveals a complex landscape where model selection should be guided by specific research objectives and experimental constraints. Traditional FBA approaches, particularly those based on highly curated models like EcoCyc-18.0-GEM, provide robust performance for standard conditions but face limitations in handling regulatory complexity and strain-specific adaptations [25]. Hybrid FBA-machine learning methods such as FlowGAT and NEXT-FBA offer enhanced predictive capabilities by integrating mechanistic models with data-driven pattern recognition, though they require more sophisticated computational infrastructure and training data [35] [3].

For researchers focusing on drug target identification, two-stage FBA provides distinct advantages by explicitly incorporating safety considerations through side effect minimization [38]. Alternatively, topology-based machine learning approaches demonstrate that structural network properties alone can provide powerful essentiality predictions, potentially complementing flux-based methods [39].

Future methodology development should focus on improving gene-protein-reaction mappings, incorporating regulatory constraints, and developing condition-specific biomass objectives to enhance prediction accuracy across diverse environmental contexts. The integration of multi-omics data with constraint-based modeling represents a promising avenue for creating context-specific models with improved biological relevance for both basic research and therapeutic development.

Dynamic Flux Balance Analysis (dFBA) is a powerful computational framework that enables researchers to simulate the dynamic metabolic behavior of microorganisms in changing environments. By combining the steady-state constraints of Flux Balance Analysis (FBA) with kinetic models of extracellular metabolite concentrations, dFBA provides a platform for predicting time-dependent changes in microbial growth, substrate consumption, and product formation [31]. This approach is particularly valuable for modeling multi-strain systems and co-cultures, where microbial interactions such as competition, cross-feeding, and syntrophy significantly impact community dynamics and function. The ability to predict these interactions is crucial for applications in drug development, where gut microbiome metabolism can influence drug efficacy, and in biotechnology, where microbial consortia are engineered for sustainable bioproduction.

For researchers working with E. coli metabolic networks, selecting appropriate dFBA implementation is critical for obtaining reliable simulations. Different computational approaches have been developed to address the unique challenges of dynamic metabolic modeling, each with distinct strengths and limitations. This guide provides an objective comparison of current dFBA methodologies, supported by experimental data and detailed protocols, to inform model selection for multi-strain systems.

Core Computational Approaches for dFBA Implementation

Fundamental Methodologies