Improving Metabolic Model Predictions: A Guide to Addressing Thermodynamic Feasibility

Thermodynamic feasibility is a critical but often overlooked constraint in genome-scale metabolic models (GEMs).

Improving Metabolic Model Predictions: A Guide to Addressing Thermodynamic Feasibility

Abstract

Thermodynamic feasibility is a critical but often overlooked constraint in genome-scale metabolic models (GEMs). Ignoring the laws of thermodynamics can lead to predictions of biologically impossible pathways, directly impacting the reliability of models used in metabolic engineering and drug discovery. This article provides a comprehensive guide for researchers and scientists on integrating thermodynamic constraints into metabolic networks. We explore the foundational principles of network thermodynamics, review current methodological frameworks like ETGEMs and probabilistic analysis, and present practical strategies for troubleshooting common prediction anomalies. By comparing the performance and applications of different constraint-based models, we demonstrate how incorporating thermodynamic reality significantly enhances prediction accuracy for pathway analysis, phenotype prediction, and the identification of feasible metabolic engineering targets.

The Thermodynamic Imperative: Why Your Metabolic Model Needs Energy Constraints

The Problem of Thermodynamically Infeasible Fluxes in Stoichiometric Models

Frequently Asked Questions (FAQs)

1. What are thermodynamically infeasible fluxes, and why are they a problem in my model? Thermodynamically infeasible fluxes are metabolic flux distributions predicted by constraint-based models, like Flux Balance Analysis (FBA), that violate the laws of thermodynamics. The most common violation is the presence of thermodynamically infeasible cycles (TICs), which are closed loops of reactions that could, in principle, perform work without consuming free energy [1]. These cycles are "unphysical" because metabolism in a non-equilibrium steady state must proceed along routes where the Gibbs energy decreases [2]. Their presence in your solution can lead to incorrect predictions of metabolic capabilities, unrealistic yield calculations, and ultimately, flawed biological conclusions [1] [3].

2. My FBA solution suggests high growth with no nutrient uptake. Could this be caused by an infeasible cycle? Yes, this is a classic symptom of a thermodynamically infeasible cycle, often referred to as a "futile" cycle [1]. These cycles can generate ATP or biomass precursors in a loop without any net input of nutrients, which is biochemically impossible. To verify, you should run a thermodynamic feasibility check on your flux distribution.

3. How can I check if my flux distribution contains thermodynamically infeasible cycles? Checking for feasibility involves testing whether a vector of chemical potentials (μ) exists that satisfies the condition μ * Ω > 0, where Ω is a matrix constructed from your flux vector (v) and the stoichiometric matrix (S) [1] [2]. If no such vector exists, your flux distribution is thermodynamically infeasible. Computationally, this can be done using relaxation algorithms to solve for μ, or by using specialized tools like tEFMA which directly computes only thermodynamically feasible elementary flux modes [4].

4. What are the main methods for removing infeasible cycles from my model? There are several strategies, which can be categorized as "local" or "global":

- Loop-Specific Correction: This method first identifies the specific cyclic pathway (e.g., using a Monte Carlo procedure [1]) and then removes it by applying "ad hoc rules." A local rule might exploit the fact that fluxes in a cycle can be adjusted by a constant without breaking mass balance [1] [2].

- Integration of Thermodynamic Constraints: A more robust approach is to prevent these cycles from appearing in the first place by adding thermodynamic constraints directly into your modeling framework. This can be done by:

- Constraining Reaction Directionality: Using thermodynamic data to set correct lower and upper bounds (e.g., υr ≥ 0 for irreversible reactions) [3] [5].

- Advanced Frameworks: Using models that integrate both enzymatic and thermodynamic constraints (ETGEMs) or tools like Find_tfSBP to find the smallest balanced pathways that are thermodynamically feasible [6] [7].

Troubleshooting Guide

Problem: Flux Balance Analysis Predicts Theoretically Impossible Yields

Description Your FBA simulation for a bioproduction strain (e.g., for 1,4-butanediol in E. coli) predicts a product yield that seems too high, or you have identified a closed loop of reactions that generate energy or redox cofactors without any substrate input.

Diagnosis Steps

- Identify Null Production: Run an FBA simulation with all uptake reactions set to zero. If the model still predicts non-zero flux through biomass or your target product, this is a strong indicator of one or more TICs [1].

- Check Thermodynamic Feasibility: Formally check your flux solution for thermodynamic feasibility using the condition μ * Ω > 0 [1] [2]. Many research papers provide algorithms and code for this check.

- Locate the Cycle: Use a loop detection algorithm. For large, genome-scale networks, a combination of a relaxation algorithm and a Monte Carlo procedure has been shown to effectively identify these computationally challenging loops [1] [2].

Resolution Methods

- Manual Curation: If the loop is small, you can manually adjust the directionality of one reaction in the cycle to break it, based on literature or database evidence (e.g., from BRENDA or MetaCyc).

- Algorithmic Correction: Apply a correction method to your flux vector. For example, after a loop

kis identified, you can adjust the flux vectorvto a new feasible vectorv'by subtracting the cycle, ensuring that all other constraints (like mass balance) are still satisfied [2]. - Use Feasibility-First Tools: Switch to pathway analysis tools that incorporate thermodynamics from the start. For example, use tEFMA instead of standard EFM analysis, or use Find_tfSBP to find pathways that are stoichiometrically balanced and thermodynamically feasible by design [6] [4].

Problem: Model Fails to Produce a Known Metabolite After Gene Knockout

Description After simulating a gene knockout, your model fails to produce an essential metabolite, even though you know an alternative pathway exists in the organism.

Diagnosis Steps

- Check Pathway Thermodynamics: The alternative pathway might be thermodynamically constrained. Calculate the standard Gibbs free energy change (ΔrG'°) for the reactions in the pathway. Tools using group contribution methods can estimate this for reactions where experimental data is unavailable [8].

- Analyze Metabolite Concentrations: The pathway might only be feasible within a specific range of metabolite concentrations. Incorporate plausible intracellular metabolite concentration ranges into your model to check if the reaction directionality is constrained under physiological conditions [3].

Resolution Methods

- Refine Reaction Bounds: Update the model's reversibility/irreversibility constraints based on your thermodynamic analysis.

- Integrate Quantitative Constraints: Use a framework that includes metabolite concentrations and thermodynamic constraints directly in the FBA calculation. This can be formulated as a Mixed Integer Linear Programming (MILP) problem that finds an optimal flux distribution and metabolite profile consistent with thermodynamics [3].

The table below lists several software tools and algorithms that can help diagnose and resolve thermodynamic feasibility issues.

| Tool/Method Name | Primary Function | Key Feature |

|---|---|---|

| tEFMA [4] | Computes thermodynamically feasible Elementary Flux Modes. | Uses metabolome data to avoid enumerating infeasible EFMs, saving memory and runtime. |

| Find_tfSBP [6] | Identifies the smallest balanced pathways (SBPs) that are thermodynamically feasible. | Uses Mixed Integer Programming (MIP) and considers high product yield. |

| Loop Correction Method [1] [2] | Identifies and removes infeasible loops from a given flux distribution. | Combines a relaxation algorithm with a Monte Carlo procedure for loop detection in large networks. |

| ETGEMs [7] | Integrates both Enzymatic and Thermodynamic constraints into Genome-scale Models. | Excludes pathways that are enzymatically costly and thermodynamically unfavorable simultaneously. |

| Thermodynamic FBA [3] | Incorporates thermodynamic realizability as a direct constraint on FBA solutions. | Uses a MILP approach to find flux distributions consistent with metabolite concentration ranges. |

Experimental Protocols

Protocol 1: Detecting Thermodynamically Infeasible Cycles in a Flux Distribution

Objective: To verify whether a flux vector v obtained from FBA is thermodynamically feasible.

Materials:

- The stoichiometric matrix (S) of your metabolic model.

- The flux distribution vector (v) to be tested.

Methodology:

- Pre-process the Flux Vector: Create a reduced flux vector

v'by excluding uptake reactions, biomass reactions, and any reaction with a flux of zero [1]. - Construct the Ω Matrix: For each reaction in

v', calculate its element in the Ω matrix as Ωmr = -sign(v'r) * Smr [1] [2]. - Check for Feasibility: Determine if a non-zero vector of chemical potentials (μ) exists that satisfies the inequality μ * Ω > 0. This can be efficiently computed using a relaxation algorithm [1] [2].

- Interpretation: If the relaxation algorithm finds a solution for μ, the flux distribution is thermodynamically feasible. If no solution exists, the flux distribution contains at least one infeasible cycle.

Protocol 2: Integrating Thermodynamic Constraints into FBA

Objective: To directly compute a thermodynamically feasible flux distribution using FBA.

Materials:

- A genome-scale metabolic model (e.g., in SBML format).

- Estimated standard Gibbs free energy (ΔrG'°) for reactions (e.g., from group contribution methods).

- Plausible ranges for intracellular metabolite concentrations (from literature or experiments).

Methodology:

- Formulate the Base FBA Problem:

- Add Thermodynamic Constraints:

- The fundamental rule is sgn(v) = -sgn(ΔGr) for each reaction, where ΔGr is the actual Gibbs free energy change [3].

- ΔGr is calculated as: ΔGr = ΔGr0 + RT * (Σln[P] - Σln[S]), where [S] and [P] are substrate and product concentrations [3].

- To implement this linearity, binary variables are often introduced to handle the reaction directionality, converting the problem into a Mixed Integer Linear Program (MILP) [3].

- Solve the MILP: Use a MILP solver to find the flux distribution that maximizes your objective function while satisfying both the stoichiometric and thermodynamic constraints.

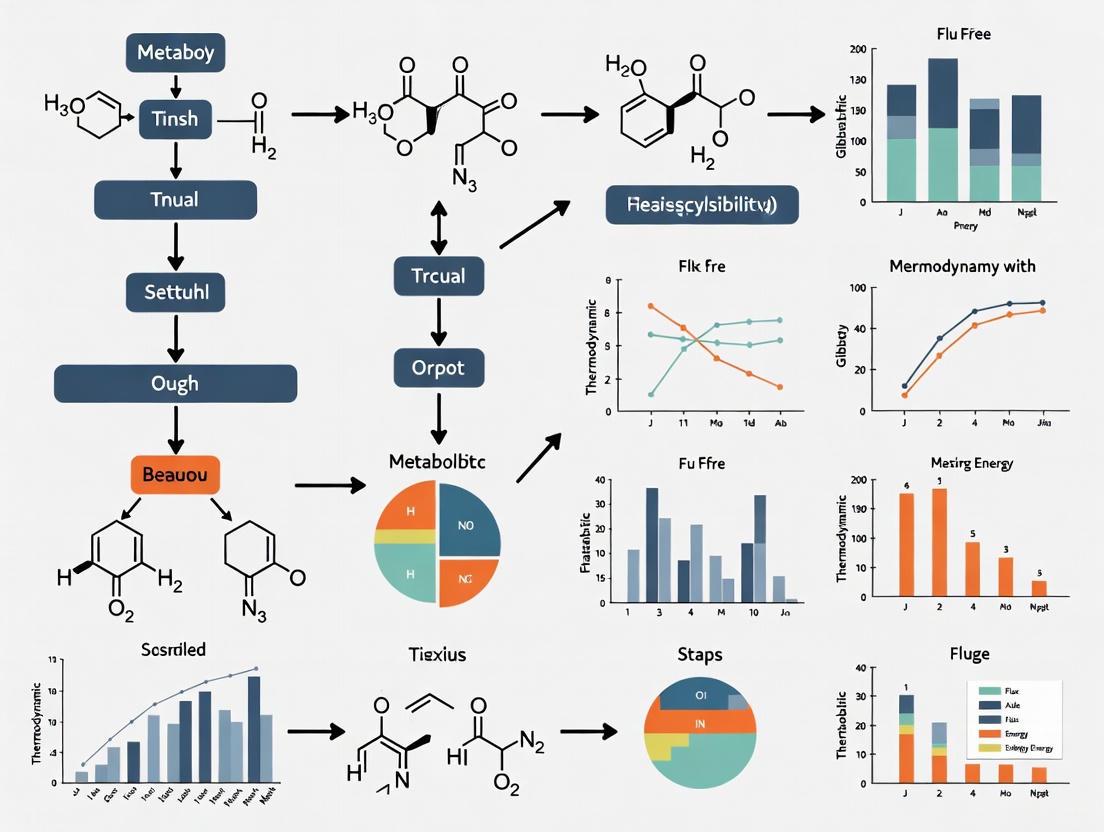

Workflow Visualization

The following diagram illustrates a general workflow for diagnosing and resolving thermodynamically infeasible fluxes, integrating the FAQs and protocols above.

This table outlines key databases and computational resources essential for conducting thermodynamic analyses of metabolic models.

| Item Name | Function / Application | Key Features |

|---|---|---|

| BioCyc/MetaCyc [9] | Database of metabolic pathways and enzymes. | Provides curated information on metabolic reactions and pathways for many organisms, useful for manual curation of reaction directionality. |

| BRENDA [9] | Comprehensive enzyme database. | Allows searching for enzyme-specific information, including reaction reversibility and organism-specific details. |

| Group Contribution Method [8] | Algorithm for estimating ΔrG'°. | Predicts standard Gibbs free energy changes for biochemical reactions where experimental data is unavailable. |

| ModelSEED [9] | Online resource for metabolic model reconstruction. | Can be used to automatically generate draft models, which can then be refined with thermodynamic constraints. |

| BiGG Models [9] | Knowledgebase of genome-scale metabolic networks. | Provides access to curated, stoichiometrically balanced models that can serve as a high-quality starting point for analysis. |

Core Concepts: Gibbs Free Energy

Gibbs Free Energy (ΔG) is a fundamental concept used to determine the spontaneity and directionality of a chemical reaction. It combines the system's enthalpy (ΔH) and entropy (ΔS) into a single value [10] [11].

Foundational Equation: ΔG = ΔH - TΔS Where:

- ΔG is the change in Gibbs Free Energy

- ΔH is the change in enthalpy (heat content)

- T is the temperature in Kelvin

- ΔS is the change in entropy (disorder)

Reaction Spontaneity and ΔG

| ΔG Value | Thermodynamic Favorability | Reaction Type | Key Characteristic |

|---|---|---|---|

| ΔG < 0 (Negative) | Spontaneous | Exergonic | Proceeds forward without energy input [10] [11] |

| ΔG > 0 (Positive) | Non-spontaneous | Endergonic | Requires energy input to proceed [10] [11] |

| ΔG = 0 | System at Equilibrium | - | Forward and reverse rates are equal [10] |

Predicting Reaction Behavior

The signs of ΔH and ΔS determine how temperature affects spontaneity [10] [11]:

| ΔH | ΔS | Thermodynamic Favorability | Example |

|---|---|---|---|

| Negative (Exothermic) | Positive (ΔS > 0) | Always spontaneous at all temperatures | Combustion reactions |

| Negative (Exothermic) | Negative (ΔS < 0) | Spontaneous only at low temperatures | Water freezing |

| Positive (Endothermic) | Positive (ΔS > 0) | Spontaneous only at high temperatures | Evaporation of water |

| Positive (Endothermic) | Negative (ΔS < 0) | Never spontaneous at any temperature |

Relationship Between ΔG° and the Equilibrium Constant (K)

Under standard conditions, ΔG° relates to the equilibrium constant K [10]: ΔG° = -RT ln K

| Relationship of K | ΔG° Value | Product Abundance at Equilibrium |

|---|---|---|

| K > 1 | ΔG° < 0 (Negative) | Products are more abundant [10] |

| K < 1 | ΔG° > 0 (Positive) | Reactants are more abundant [10] |

| K = 1 | ΔG° = 0 | Reactants and products are comparably abundant [10] |

Troubleshooting Guide: FAQs on Reaction Directionality

FAQ 1: My calculated ΔG is positive, yet the reaction proceeds observably in the forward direction. What could explain this discrepancy?

A positive ΔG° indicates non-spontaneity under standard conditions (1 M concentration, 1 atm pressure). However, actual cellular or experimental conditions differ significantly [10].

Troubleshooting Protocol:

- Check Reaction Quotient (Q): Calculate the actual ΔG using ΔG = ΔG° + RT ln Q. If Q is small (product concentrations low), the RT ln Q term can make ΔG negative, allowing the reaction to proceed [10].

- Verify Metabolic Coupling: In metabolic networks, thermodynamically unfavorable reactions (positive ΔG) are often driven by coupling with highly favorable reactions (e.g., ATP hydrolysis) [12] [13].

- Confirm Assumed Standard State: Ensure that standard free energy values (ΔG°') used in calculations are referenced for the correct pH, ionic strength, and temperature relevant to your biological system.

FAQ 2: How can I systematically assign reaction directions in a large-scale metabolic model when thermodynamic data is incomplete?

Manually curating directionality for genome-scale models is challenging. Computational algorithms can automate this process using available data and heuristic rules [12] [14].

Methodology:

- Exploit Available Thermodynamic Data: First, identify irreversible reactions using experimentally derived Gibbs energies of formation where available [12].

- Apply Network Topology Heuristics: The algorithm identifies reaction subsets that could theoretically create thermodynamically infeasible energy cycles. It then assigns directions to disable such cycles [12].

- Implementation Example: In a study on an E. coli metabolic model, this systematic approach automatically assigned 130 irreversible reactions out of 920 total, covering about 70% of the required irreversible reactions to prevent infeasible energy production [12].

FAQ 3: What experimental and computational approaches can reduce uncertainty in determining intracellular reaction directionality?

Uncertainty in flux values and reaction properties arises from a lack of intracellular measurements [14].

Computational & Experimental Integration:

- Apply Thermodynamics-Based Metabolite Sensitivity Analysis (TMSA): This method combines constraint-based modeling and sensitivity analysis to rank metabolites based on their ability to constrain possible solutions to a limited, thermodynamically consistent set of internal states when measured [14].

- Guide Targeted Measurements: The TMSA output prioritizes which intracellular metabolite concentrations to measure experimentally. Measuring high-impact metabolites significantly reduces uncertainty in flux estimations and reaction directionality [14].

- Iterative Refinement: Use new experimental concentration data to refine the metabolic model, leading to more accurate predictions of reaction directions and thermodynamic driving forces [13] [14].

The Scientist's Toolkit: Computational Thermodynamics

| Research Reagent / Resource | Function / Application |

|---|---|

| Genome-Scale Metabolic Model | A computational representation of an organism's metabolism, used as a framework for applying thermodynamic constraints [12] [14]. |

| Gibbs Energy of Formation (ΔfG°) Data | Experimental thermodynamic data for metabolites; used as a primary input to calculate reaction Gibbs energies and identify irreversible reactions [12]. |

| Thermodynamics-Based Flux Analysis (TFA) | A constraint-based modeling method that integrates thermodynamic constraints with flux balance analysis to estimate metabolically feasible flux distributions [14]. |

| Reaction Directionality Algorithm | Computational tool that automatically assigns reaction directions in a metabolic network to ensure thermodynamic feasibility and prevent infeasible energy production cycles [12]. |

| 3-Methyl-4-methylsulfonylphenol | 3-Methyl-4-methylsulfonylphenol, CAS:14270-40-7, MF:C8H10O3S, MW:186.23 g/mol |

| 3'-(Hydroxymethyl)-biphenyl-4-acetic acid | 3'-(Hydroxymethyl)-biphenyl-4-acetic Acid|CAS 176212-50-3 |

Experimental and Computational Workflow

The following diagram illustrates the integrated computational and experimental workflow for investigating thermodynamics in metabolic networks.

The Impact of Metabolite Concentrations on Thermodynamic Driving Forces

Troubleshooting Common Thermodynamic Feasibility Analysis Issues

FAQ 1: My metabolic network model contains thermodynamically infeasible loops. How can I identify and eliminate them?

Issue: Flux Balance Analysis (FBA) can produce flux distributions that include thermodynamically infeasible cycles, where metabolites are consumed and regenerated without a net change, violating the second law of thermodynamics.

Solution: Implement Thermodynamic Metabolic Flux Analysis (TMFA) to constrain your model.

- Root Cause: Standard FBA only considers mass balance constraints (stoichiometry) but ignores energy conservation. Internal cycles can form that are mathematically possible but physically impossible because they would produce energy without substrate input.

- Diagnostic Steps:

- Run Flux Variability Analysis (FVA) on your model. If reactions can carry non-zero flux while the objective function (e.g., growth) is zero, this may indicate a loop.

- Use tools like

CycleFreeFluxto detect thermodynamically infeasible loops in flux distributions [15].

- Resolution Protocol:

- Formulate a TMFA: Incorporate thermodynamic constraints into your model. This requires:

- Apply Mixed-Integer Linear Programming (MILP): The TMFA algorithm uses MILP to eliminate flux cycles by ensuring that all reactions proceed in a thermodynamically feasible direction (negative ΔrG' for the actual flux direction) [16]. The core constraint is that the Gibbs free energy change, ΔrG' = ΔrG'° + RT * Sᵀ * ln(x), must be negative for reactions carrying forward flux.

FAQ 2: The predicted thermodynamic driving force for my pathway is low. How can I identify the specific bottleneck reactions?

Issue: Pathway analysis reveals a low Max-min Driving Force (MDF), suggesting limited thermodynamic feasibility, but the specific problematic reactions are unknown.

Solution: Perform MDF or Network-Embedded MDF (NEM) analysis.

- Root Cause: One or more reactions in the pathway operate close to equilibrium (ΔrG' ≈ 0), creating a bottleneck that limits the flux through the entire pathway.

- Diagnostic Steps: Calculate the MDF for your pathway. The MDF is the maximum value of the minimum driving force across all reactions in the pathway, optimized over possible metabolite concentrations [18].

- Resolution Protocol:

- Use MDF Analysis Tools: Employ software like

OptMDFpathwayor thethermosamplerpackage'smdf.pyscript [18] [17]. - Input Requirements:

- The reaction network (stoichiometry).

- Standard Gibbs free energies (ΔrG'°) for all reactions.

- Physiologically plausible min/max metabolite concentration bounds.

- (Optional) Known metabolite concentration ratios.

- Interpret Output: The analysis will return the MDF value and the metabolite concentration profile that achieves it. Reactions with a driving force equal to the MDF are the thermodynamic bottlenecks [18]. For example, in E. coli glycolysis, the PPi-dependent phosphofructokinase (PPi-PFK) reaction was identified as a major bottleneck with a driving force of only -1.45 kJ/mol, much lower than its ATP-dependent counterpart [19].

- Use MDF Analysis Tools: Employ software like

Table 1: Troubleshooting Guide for Thermodynamic Analysis

| Problem | Primary Cause | Diagnostic Tool | Solution Approach |

|---|---|---|---|

| Thermodynamically Infeasible Loops | Lack of energy conservation in model | Flux Variability Analysis (FVA), TMFA | Integrate thermodynamic constraints via TMFA [16] |

| Low Pathway Driving Force | Reactions operating near equilibrium | Max-min Driving Force (MDF) Analysis [18] | Identify & engineer bottleneck reactions [19] |

| Infeasible ΔrG' ranges | Incorrect standard energy or concentration bounds | Thermodynamic Variability Analysis (TVA) [16] | Re-estimate ΔrG'°, refine concentration constraints |

Advanced Thermodynamic Analysis: Protocols and Data

Experimental Protocol 1: Quantifying Thermodynamic Driving Forces in a Native Pathway

Aim: To measure the in vivo metabolite concentrations and calculate the actual Gibbs free energy change (ΔrG') for reactions in a pathway of interest.

Background: The actual driving force of a reaction is calculated as ΔrG' = ΔrG'° + RT * ln(Q), where Q is the mass-action ratio (product/substrate concentrations). Measuring intracellular concentrations is therefore essential [20].

Materials:

- Quenching Solution: Cold methanol, dry ice/ethanol bath, or similar to instantly halt metabolism.

- Extraction Solvent: Methanol/water or acetonitrile/water mixtures for metabolite extraction.

- Internal Standards: Isotopically labeled (¹³C or ¹âµN) versions of target metabolites.

- Analytical Platform: LC-MS/MS system for absolute quantification of metabolites.

Procedure:

- Culture Sampling: Rapidly withdraw culture and quench metabolism (e.g., into -40°C methanol).

- Metabolite Extraction: Subject cells to repeated freeze-thaw cycles in extraction solvent. Centrifuge to remove cell debris.

- Sample Analysis: Analyze the supernatant via LC-MS/MS. Use internal standards for absolute quantification.

- Data Calculation:

- For each metabolite, determine the intracellular concentration (considering cell volume).

- For each reaction, calculate the reaction quotient, Q.

- Obtain ΔrG'° values from databases (e.g., eQuilibrator) or literature.

- Compute ΔrG' = ΔrG'° + RT * ln(Q).

Expected Outcome: A profile of reaction driving forces for the pathway, revealing which steps are near equilibrium (ΔrG' ≈ 0) and which are far from equilibrium (large negative ΔrG'), thus identifying potential regulatory points [20].

Experimental Protocol 2: Engineering a Pathway for Increased Thermodynamic Driving Force

Aim: To re-engineer a metabolic pathway by replacing a bottleneck reaction to increase its MDF and improve product titers.

Background: This protocol is based on the successful engineering of PPi-free glycolysis in Clostridium thermocellum, which increased ethanol titers by 38% [19].

Materials:

- Engineering Chassis: The host organism (e.g., C. thermocellum).

- Genetic Tools: Plasmids for gene expression, CRISPR-Cas9 for gene knockouts.

- Key Genetic Parts:

- Gene for ATP-dependent PFK (ATP-pfk) to replace native PPi-PFK.

- Gene for soluble pyrophosphatase (PPase) to degrade PPi.

- Gene for pyruvate kinase (pyk) to provide an ATP-generating step.

- Analytics: HPLC for ethanol and substrate quantification, LC-MS for intracellular metabolites.

Procedure:

- Identify the Bottleneck: Use MDF analysis on the native pathway. In C. thermocellum, the PPi-PFK and PPDK reactions were bottlenecks [19].

- Design the New Pathway:

- Replace the native PPi-pfk gene with an ATP-pfk gene.

- Delete the pyruvate phosphate dikinase (ppdk) gene.

- Introduce genes for soluble PPase and pyruvate kinase (pyk).

- Strain Construction: Use genetic engineering tools (e.g., homologous recombination, CRISPR) to implement the above changes.

- Phenotypic Validation:

- Measure growth and product (ethanol) titers in bioreactors.

- Quantify intracellular metabolites to confirm the reduction in pathway reversibility and increased levels of lower glycolysis intermediates.

- Re-calculate the driving forces for the engineered pathway.

Expected Outcome: A significant increase in the thermodynamic driving force of the targeted reaction and the overall pathway, leading to higher product yields and titers [19].

Diagram: Workflow for Engineering Thermodynamic Driving Force.

Data Presentation: Thermodynamic Properties of Glycolytic Reactions

Table 2: Comparative Driving Forces in Native and Engineered Glycolysis of C. thermocellum [19]

| Reaction | Cofactor | ΔrG' in Wild-Type (kJ/mol) | ΔrG' in Engineered Strain (kJ/mol) | Physiological Implication |

|---|---|---|---|---|

| Phosphofructokinase (PFK) | PPi | -1.45 | ≈ -22.6 (ATP-PFK) | Low driving force in WT leads to high reversibility; engineering creates a strong, irreversible commitment step. |

| Phosphofructokinase (PFK) | ATP | -22.57 (in T. saccharolyticum) | N/A | Benchmark from an organism with canonical glycolysis. |

| Pyruvate Kinase (PYK) | N/A | N/A | Large negative ΔrG' | Provides a strong driving force for the final step to pyruvate, pulling flux through lower glycolysis. |

Table 3: Key Thermodynamic Analysis Methods and Their Applications

| Method | Primary Function | Underlying Principle | Key Inputs | Reported Application/Outcome |

|---|---|---|---|---|

| TMFA [16] | Eliminate thermodynamically infeasible loops | MILP with thermodynamic constraints | ΔrG'°, Concentration bounds | Identified regulated reactions in E. coli and G. sulfurreducens consistent with gene expression data. |

| MDF [18] | Find pathway with highest minimal driving force | Linear Optimization | Pathway, ΔrG'°, Concentration bounds | Identified 145 CO₂-fixing product pathways in E. coli; revealed thermodynamic bottlenecks. |

| Probabilistic Thermodynamic Analysis [15] | Sample feasible flux & concentration space | Markov Chain Monte Carlo (MCMC) | ΔrG'°, Flux constraints | Predicted multimodal flux distributions and reaction directions in E. coli. |

| Thermosampler [17] | Explore full space of feasible metabolite concentrations | Hit-and-run Monte Carlo sampling | ΔrG'°, Concentration & ratio constraints | Used to analyze lysine biosynthesis and TCA cycle thermodynamics in E. coli and Synechocystis. |

Table 4: Key Research Reagent Solutions for Thermodynamic Analysis

| Tool / Reagent | Function / Purpose | Example / Source |

|---|---|---|

| Genome-Scale Model | Stoichiometric backbone for constraint-based analysis | iJO1366 (E. coli) [18], iML1515 [7] |

| Group Contribution Method | Estimate standard Gibbs free energy (ΔrG'°) | eQuilibrator database [19], Component Contribution method [16] |

| Thermodynamic Analysis Software | Perform MDF, TMFA, and sampling | OptMDFpathway [18], thermosampler [17], Probabilistic Thermodynamic Analysis (PTA) package [15] |

| Genetic Engineering Tools | Modify pathways to improve thermodynamics | CRISPR-Cas9, Plasmid Vectors (for gene expression/knockout) [19] |

| LC-MS/MS with Isotopic Standards | Absolute quantification of intracellular metabolite concentrations | Protocol from [20]; Internal standards for quantitation |

Identifying Thermodynamically Infeasible Cycles and Energy-Generating Loops

Frequently Asked Questions

1. What are thermodynamically infeasible cycles and why are they a problem in metabolic models?

Thermodynamically infeasible cycles, also known as energy-generating loops or thermodynamically infeasible loops, are sets of reactions within a genome-scale metabolic model (GSMM) that are capable of sustaining arbitrarily large, non-zero fluxes without any net consumption of substrates [21]. These loops violate the second law of thermodynamics because they ostensibly generate energy or recycle cofactors without any net input. Their presence is a common source of error that can severely compromise the accuracy of flux predictions, such as those generated by Flux Balance Analysis (FBA), leading to unrealistic simulations of cellular growth and metabolic function [21] [22].

2. How can I check if my metabolic model contains these infeasible loops?

You can identify these loops using specialized software tools that analyze the network topology and flux constraints of your model. The Loop Test in the MACAW (Metabolic Accuracy Check and Analysis Workflow) suite is one such method [21]. This test works by blocking all exchange reactions (uptake and secretion) in the model and then identifying all reactions that can still carry a non-zero flux. These reactions are necessarily part of internal cycles. MACAW has an advantage because it not only identifies these reactions but also groups them into distinct loops, making it easier to investigate and correct the underlying errors [21]. Other tools like MEMOTE and ErrorTracer also include tests for detecting thermodynamically infeasible cycles [21].

3. What are the common causes of these cycles in a model?

Infeasible loops often arise from inaccuracies in the model's reconstruction or curation. Common causes include [21]:

- Duplicate Reactions: The presence of two or more identical (or near-identical) reactions that can create a futile cycle.

- Incorrect Reaction Reversibility: A reaction that is annotated as reversible but, in reality, only proceeds in one direction under physiological conditions.

- Missing or Inaccurate Constraints: The lack of appropriate thermodynamic or regulatory constraints on reaction fluxes.

4. What is the difference between a "loop" and a "dilution" problem?

Both are distinct but related pathway-level errors that affect model accuracy.

- A Loop involves a cycle of reactions that can generate infinite flux without any net input, which is thermodynamically impossible [21].

- A Dilution problem, identified by MACAW's "Dilution Test," involves metabolites (often cofactors like ATP/ADP) that can be interconverted or recycled but cannot be net produced from external nutrients. Since cells grow and divide, diluting their internal metabolite pools, the inability to net produce a core metabolite indicates a gap in the biosynthesis or uptake pathways for that metabolite [21].

5. Does fixing these loops improve model predictions?

Yes. Correcting these errors enhances the biological fidelity of your model. For example, after using MACAW to identify and correct errors in the human metabolic model (Human-GEM), the revised model showed an improved ability to accurately predict the growth outcomes following genetic knockouts in the lipoic acid biosynthesis pathway [21].

Troubleshooting Guide: Identifying and Resolving Infeasible Loops

Workflow Overview:

The following diagram illustrates the systematic process for detecting and correcting thermodynamically infeasible cycles in a metabolic model.

Protocol Details:

Step 1: Run a Loop Detection Test

- Objective: To identify all reactions capable of carrying flux in a closed system.

- Methodology: Use the

loop_testfunction in the MACAW tool. The underlying algorithm performs a constraint-based analysis by blocking all exchange reactions (simulating a closed system with no nutrient uptake or waste secretion) and then uses linear programming to find reactions that can still carry flux [21]. - Expected Output: A list of reactions and, crucially, the distinct loops they form.

Step 2: Analyze the Identified Loops

- Manually examine each loop grouped by MACAW. Assess the biological plausibility of the reaction set. Common suspects include energy metabolism (e.g., ATP hydrolysis cycles) and cofactor recycling (e.g., NADH/NAD+) [21].

Step 3: Inspect Individual Reactions and GPR Rules

- For each reaction in an infeasible loop, check its:

- Stoichiometry: Ensure all metabolites and their coefficients are correct.

- Reversibility: Verify if the reaction directionality is biologically accurate. A reaction annotated as reversible might be the root cause.

- Gene-Protein-Reaction (GPR) Associations: Ensure the correct genes are linked to the reaction [23].

Step 4: Apply Model Corrections

- Refine Reaction Reversibility: Change a reversible reaction to irreversible if supported by literature or thermodynamic data (e.g., from component contribution method or equilibrium constant calculations) [24].

- Remove or Consolidate Duplicate Reactions: Use MACAW's

duplicate_testto find redundant reactions and remove them or update their GPR rules [21]. - Add Missing Constraints: Implement thermodynamic constraints if your simulation environment supports them.

Step 5: Validate the Curated Model

- Re-run the loop test to confirm the infeasible cycles are resolved.

- Perform functional tests, such as FBA under different growth conditions, to ensure the model still produces biologically realistic predictions and biomass yields [23] [22].

The Scientist's Toolkit: Research Reagent Solutions

Table 1: Key Software Tools for Identifying and Correcting Thermodynamically Infeasible Loops.

| Tool Name | Primary Function | Brief Description of Utility |

|---|---|---|

| MACAW [21] | Suite of error detection tests | Provides a dedicated "Loop Test" that groups reactions into distinct loops and a "Dilution Test" for identifying cofactor production gaps. |

| MEMOTE [21] | Model quality assessment | Includes a test suite for checking for thermodynamically infeasible cycles among other common model errors. |

| ErrorTracer [21] | Error identification and context | Identifies problematic reactions and provides an annotated network to give context for manual curation. |

| Cobrapy [25] | Constraint-based modeling in Python | A core platform for running FBA. Can be used with custom scripts to detect loops by finding fluxes when exchanges are blocked. |

| Moped [25] | Model construction & analysis | A Python package that supports metabolic network expansion and can be used to investigate network topology. |

| ModelSEED / KBase [26] | Model reconstruction & gap-filling | An online platform for building, gap-filling, and analyzing metabolic models, which includes checks for network consistency. |

| ePC-SAFT [24] | Thermodynamic calculations | A thermodynamic model used to calculate activity-based equilibrium constants, which can inform more accurate reaction reversibility constraints. |

| Furo[3,2-b]pyridine-6-carboxylic acid | Furo[3,2-b]pyridine-6-carboxylic acid, CAS:122535-04-0, MF:C8H5NO3, MW:163.13 g/mol | Chemical Reagent |

| 2-[(4-Nitrophenyl)carbamoyl]benzoic acid | 2-[(4-Nitrophenyl)carbamoyl]benzoic Acid | High-purity 2-[(4-Nitrophenyl)carbamoyl]benzoic acid (CAS 6307-10-4) for research. This chemical building block is For Research Use Only. Not for human or veterinary use. |

Experimental Protocol: Loop Detection with MACAW

Title: A Computational Protocol for Detecting Thermodynamically Infeasible Loops in Genome-Scale Metabolic Models using MACAW.

1. Software Installation and Setup

- Requisite Tools: Ensure Python (v3.7+) is installed. Install the MACAW package, available from its official repository, along with its dependencies (e.g., Cobrapy, SciPy, NumPy).

- Input Data: A genome-scale metabolic model in a standard format (SBML).

2. Execution of the Loop Test

- Load your metabolic model into the MACAW environment.

- Run the primary loop detection function. The algorithm will [21]: a. Apply constraints to set the bounds of all exchange reactions to zero. b. Use linear programming to find a flux vector that satisfies mass balance and reaction bounds in this closed system. c. Identify all reactions with non-zero flux in this state. d. Group these reactions into connected sets representing distinct loops.

3. Data Analysis and Interpretation

- The output will be a list of loops. Investigate each loop as a potential error.

- Positive Control: Some models may contain known energy-generating loops (e.g., from published errata) that can be used to validate the test's functionality.

- Negative Control: A model known to be thermodynamically constrained (e.g., a core metabolism model) should yield no loops when exchange reactions are closed.

4. Critical Considerations

- Infinite Loops vs. Futile Cycles: This protocol identifies infinite loops, which are mathematical artifacts. It may also highlight biologically relevant, energy-dissipating futile cycles, which require different interpretation [21] [22].

- Solver Selection: The use of efficient linear programming solvers (e.g., GLPK, SCIP) is recommended for larger models to ensure reasonable computation times [26].

From Manual Curation to Automated Assignment of Reaction Directions

Frequently Asked Questions (FAQs)

FAQ 1: Why is moving from manual curation to automated assignment of reaction directions necessary in metabolic modeling?

Manual curation of reaction directions is laborious, prone to human error, and can lead to inconsistencies across different models [27]. Automated assignment ensures a systematic, reproducible, and scalable approach. It is essential for the accurate reconstruction of genome-scale models and for performing reliable simulations, such as Flux Balance Analysis, as reaction directionality constrains the space of possible metabolic fluxes [27] [22].

FAQ 2: What is the fundamental thermodynamic principle used to determine reaction direction?

The fundamental principle is the Second Law of Thermodynamics, which states that a reaction can only proceed in the direction of a negative Gibbs energy of reaction, ΔrG [27]. This energy is calculated using the formula: ΔrG = ΔrG'° + RT ln(Q) where ΔrG'° is the standard Gibbs energy of reaction, R is the gas constant, T is temperature, and Q is the reaction quotient [28] [27]. A reaction is considered irreversible if, under all physiological concentration ranges, its ΔrG is always negative in one direction [27].

FAQ 3: Why are classic, concentration-based feasibility analyses sometimes inaccurate?

Traditional analyses often assume metabolite activity coefficients are equal to 1, meaning concentrations are used directly in place of activities [28]. However, molecular interactions with the surrounding medium (e.g., due to crowders or salts) mean activity coefficients are not unity. Neglecting this, or using oversimplified models to estimate it, leads to incorrect Q values and a misinterpretation of a reaction's thermodynamic feasibility [28]. Accurate, activity-based standard data is required.

FAQ 4: What is Max-min Driving Force (MDF) and how is it used?

MDF is a concept to identify metabolic pathways with high thermodynamic driving forces [29]. A pathway with a high MDF can facilitate high flux and/or require lower enzyme concentrations. The OptMDFpathway method is a mixed-integer linear program that identifies pathways in a genome-scale network that achieve the maximal MDF for a desired function, such as COâ‚‚ fixation, without requiring a pre-defined reaction sequence [29].

Troubleshooting Guide

Issue 1: Thermodynamically Infeasible Cycles (TICs) in the Model

- Problem: The model allows the net production of energy (e.g., ATP) without any net substrate consumption, which is thermodynamically impossible.

- Solution:

- Identify Energy Equivalents: Define the set of energy metabolites in your model (e.g., ATP, NADH, NADPH).

- Apply Algorithmic Rules: Use an algorithm that automatically identifies reaction subsets capable of converting low-energy co-substrates into high-energy counterparts [27].

- Assign Directions Systematically: The algorithm disables this cyclic operation by assigning irreversible directions to specific reactions based on thermodynamic heuristics and network topology, thus preventing "perpetual motion" in the model [27].

Issue 2: Inconsistent or Missing Standard Gibbs Energy Data

- Problem: Experimentally derived standard Gibbs energies of formation (ΔfG'°) are unavailable for many metabolites, making ΔrG'° calculations impossible or unreliable.

- Solution:

- Prioritize Experimental Data: Use experimentally determined ΔfG'° values where available for the most reliable direction assignment [27].

- Employ Group Contribution Methods: For metabolites without experimental data, use computational estimation methods, but be aware of their inherent uncertainties [27].

- Utilize Activity-Based Approaches: For critical pathways, determine activity-based standard data. This involves measuring equilibrium concentrations and using thermodynamic models (like ePC-SAFT) to calculate activity coefficients and derive true thermodynamic equilibrium constants (Ka) [28].

Issue 3: Failure of a Pathway to Carry Flux Under Physiological Concentrations

- Problem: A pathway is stoichiometrically sound but fails to operate in simulations because one or more reactions are thermodynamically unfavorable under the given metabolite concentrations.

- Solution:

- Calculate the MDF: Use tools like OptMDFpathway to compute the Max-min Driving Force for your pathway of interest [29].

- Identify Bottlenecks: The reaction with the smallest driving force (the "MDF value") is the thermodynamic bottleneck.

- Explore Workarounds: Consider engineering solutions, such as bypassing the bottleneck reaction with an alternative enzyme or modifying host conditions to adjust the relevant metabolite concentrations.

Experimental Protocols

Protocol 1: Determining Activity-Based Standard Gibbs Energy of Reaction

Purpose: To accurately determine ΔrG'° for a biochemical reaction, accounting for non-ideal conditions in the reaction medium [28].

Methodology:

- Equilibrium Measurement: Conduct the reaction using its enzyme in a buffered solution with defined initial substrate concentrations and specific medium conditions (e.g., known pH, salt, and crowder concentrations). Incubate until equilibrium is reached.

- Quantify Metabolites: Use analytical methods (e.g., HPLC) to measure the equilibrium concentrations of all substrates and products. The ratio of these concentrations is the apparent equilibrium constant, Km.

- Calculate Activity Coefficients: Use a thermodynamic model, such as the electrolyte Perturbed-Chain Statistical Associating Fluid Theory (ePC-SAFT), to predict the activity coefficients (γ) of all metabolites at the measured equilibrium concentrations and specific medium conditions [28].

- Compute the Thermodynamic Equilibrium Constant: Calculate the activity-coefficient ratio, Kγ = âˆ(γproducts)/âˆ(γsubstrates). The true thermodynamic equilibrium constant is then Ka = Km â‹… Kγ [28].

- Determine Standard Gibbs Energy: Calculate the standard Gibbs energy of reaction as ΔrG'° = -RT ln(Ka).

Protocol 2: Systematic Assignment of Reaction Directions in a Genome-Scale Model

Purpose: To automatically assign irreversible reaction directions in a metabolic network model to ensure thermodynamic feasibility [27].

Methodology:

- Input Stoichiometric Matrix: Start with a model where all internal reactions are initially considered reversible.

- Thermodynamic Facts-Based Assignment (Step 1):

- For reactions where experimentally derived ΔfG'° values are available for all metabolites, calculate the range of possible ΔrG values using physiological concentration ranges.

- If the calculated ΔrG is always negative for one direction across all plausible concentrations, assign the reaction as irreversible in that direction [27].

- Topology and Heuristic-Based Assignment (Step 2):

- Identify reactions that are critical for disabling thermodynamically infeasible energy production cycles.

- Apply a set of heuristic rules based on biochemistry and network topology (e.g., certain ATP-hydrolyzing reactions are considered irreversible) to assign further directions [27].

- Validation: The final output is a metabolically functional model with a systematically assigned set of irreversible reactions that prevent thermodynamically infeasible cycles.

Workflow Visualization

Automated Direction Assignment

Thermodynamic Feasibility Analysis

Research Reagent Solutions

Table 1: Key Reagents for Thermodynamic Studies in Metabolism

| Reagent / Solution | Function in Experiment |

|---|---|

| ePC-SAFT Model | A thermodynamic model used to predict metabolite activity coefficients in complex, non-ideal reaction mixtures, which is crucial for converting concentration-based data into activity-based equilibrium constants [28]. |

| Tris/HCl Buffer | A common buffering system used to maintain a stable pH (e.g., pH 8) during enzymatic equilibrium experiments, ensuring consistent reaction conditions [28]. |

| MgCl₂ Solution | Provides essential Mg²⺠ions, which are often a required cofactor for kinases and other enzymes (e.g., Phosphofructokinase). Its concentration can significantly shift reaction equilibria [28]. |

| Dithiothreitol (DTT) | A reducing agent used to maintain a stable redox environment and prevent the oxidation of cysteine residues in enzymes, thereby preserving their activity during long equilibrium experiments [28]. |

| Enzyme-Specific Assay Kits | Commercial kits designed for the rapid and sensitive quantification of specific metabolites (e.g., glucose-6-phosphate, ATP). These are used to accurately measure metabolite concentrations at equilibrium [28]. |

Frameworks and Tools: Integrating Thermodynamics into Metabolic Models

Addressing thermodynamic feasibility is a fundamental challenge in metabolic network models research. Stoichiometric models alone can predict thermodynamically infeasible pathways, leading to incorrect phenotype predictions and ineffective engineering targets. Computational frameworks that integrate thermodynamic constraints have been developed to overcome these limitations. This technical support center provides troubleshooting and methodological guidance for three key frameworks: ETGEMs (Enzymatic and Thermodynamic Constraints in Genome-Scale Models), ETFL (A Formulation for Flux Balance Models Accounting for Expression, Thermodynamics, and Resource Allocation Constraints), and tEFMA (Thermodynamic EFMA).

Framework Comparison and Application Guide

The table below summarizes the core characteristics, applications, and quantitative outcomes of ETGEMs, ETFL, and tEFMA.

Table 1: Key Computational Framework Comparison

| Framework | Core Innovation | Reported Application/Impact | Software/Implementation |

|---|---|---|---|

| ETGEMs [7] | Integrates both enzymatic and thermodynamic constraints into a single modeling framework (Pyomo). | Excluded thermodynamically unfavorable and enzymatically costly pathways. For example, it identified a more realistic production pathway for carbamoyl-phosphate-derived products like L-arginine [7]. | Implemented as a Pyomo model (EcoETM for E. coli) [7]. |

| ETFL [30] | Integrates constraints for expression, thermodynamics, and resource allocation into flux balance models. | Enhances phenotype prediction by simultaneously accounting for proteomic and thermodynamic limitations. | Available as a GitHub repository (EPFL-LCSB/etfl) [30]. |

| tEFMA [31] | Integrates network-embedded thermodynamics into Elementary Flux Mode Analysis (EFMA). | In the central carbon metabolism of E. coli, up to 80% of EFMs were identified as thermodynamically infeasible. Identified glutamate dehydrogenase as a thermodynamic bottleneck [31]. | Implemented as a Java package available on GitHub [31]. |

Detailed Experimental Protocols

Protocol for Constructing an ETGEMs Model

This protocol describes how to build a metabolic model with integrated enzymatic and thermodynamic constraints, as demonstrated with the EcoETM model for E. coli [7].

- Base Model Selection: Begin with a high-quality, stoichiometrically balanced Genome-Scale Metabolic model (GEM), such as iML1515 for E. coli.

- Constraint Formulation:

- Thermodynamic Constraints: Incorporate Gibbs free energy values (( \DeltaR g )) for metabolic reactions. Calculate this using the formula:

\( \Delta_R g = \Delta_R g^{0} + RT\ln(Q) \)where ( \DeltaR g^{0} ) is the standard Gibbs energy of reaction and ( Q ) is the reaction quotient. Use activity-based ( \DeltaR g^{0} ) values and metabolite activities (not just concentrations) for greater accuracy [32]. - Enzymatic Constraints: Formulate constraints based on enzyme kinetic constants (( k{cat} )) and molecular weights, linking reaction fluxes to enzyme concentration and capacity.

- Thermodynamic Constraints: Incorporate Gibbs free energy values (( \DeltaR g )) for metabolic reactions. Calculate this using the formula:

- Model Integration: Implement the combined constraints within a Pyomo optimization framework to create the unified ETGEMs model.

- Validation: Test the model's predictions against experimental data, such as growth rates or metabolite production yields, to ensure it excludes thermodynamically infeasible and enzymatically costly pathways.

Protocol for Performing tEFMA

This protocol outlines the steps to identify thermodynamically feasible Elementary Flux Modes in a metabolic network [31].

- Network Definition: Define the metabolic network for analysis, including all metabolites, reactions, and stoichiometry.

- Metabolome Data Integration: Collect or estimate intracellular metabolome data (metabolite concentrations or activities).

- Thermodynamic Filtering: During the EFMA computation, use the network-embedded thermodynamic calculations to assess the feasibility of each EFM. EFMs that require reactions to proceed in a thermodynamically infeasible direction (positive ( \Delta_R g ) for a forward reaction) are identified and removed from the final set.

- Output Analysis: Analyze the resulting smaller subset of thermodynamically feasible EFMs to characterize phenotypes, quantify network robustness, or identify metabolic engineering targets.

Framework Workflow Diagrams

ETGEMs Model Construction Workflow

tEFMA Analysis Process

ETFL Model Integration Scope

The Scientist's Toolkit: Essential Research Reagents and Materials

Table 2: Key Reagents and Computational Tools

| Item | Function / Application |

|---|---|

| Pyomo Modeling Framework [7] | An open-source optimization modeling environment in Python used for constructing and solving ETGEMs. |

| ePC-SAFT [32] | A thermodynamic model used to calculate metabolite activity coefficients, which are crucial for determining accurate, activity-based standard Gibbs energy values (( \Delta_R g^0 )). |

| tEFMA Java Package [31] | The dedicated software for performing thermodynamic EFMA, enabling the analysis of larger networks by calculating only thermodynamically feasible EFMs. |

| ETFL GitHub Repository [30] | The source code for the ETFL formulation, allowing researchers to incorporate expression, thermodynamic, and resource allocation constraints into their models. |

| Metabolome Data (e.g., LC-MS/MS) | Quantitative measurements of intracellular metabolite concentrations are essential for calculating reaction quotients (Q) and applying thermodynamic constraints in tEFMA and ETGEMs. |

| 1H-Pyrido[2,3-d][1,3]oxazine-2,4-dione | 1H-Pyrido[2,3-d][1,3]oxazine-2,4-dione, CAS:21038-63-1, MF:C7H4N2O3, MW:164.12 g/mol |

| Tert-butyl 2,5-dihydroxybenzoate | Tert-butyl 2,5-dihydroxybenzoate|C11H14O3|For Research |

Troubleshooting FAQs

Q1: My ETGEMs model is infeasible. What could be wrong? A1: Infeasibility often stems from overly stringent constraints. First, try relaxing the bounds on enzyme capacity constraints. Then, verify the thermodynamic data you are using, especially the standard Gibbs energy (( \Delta_R g^0 )) values. Ensure that the directionality of reactions enforced by thermodynamics does not conflict with essential metabolic functions in your model [7].

Q2: I am getting a "memory overflow" error when running a traditional EFMA on a large network. What are my options? A2: This is a common issue as the number of EFMs grows combinatorially. The tEFMA framework is specifically designed to address this. By integrating thermodynamic constraints, it calculates only the biologically relevant subset of EFMs, drastically reducing memory consumption and runtime [31].

Q3: How crucial is it to use activity-based equilibrium constants versus concentration-based ones? A3: Critical. Using concentration-based constants can lead to incorrect feasibility statements. Metabolite activity coefficients are often not unity in the cellular environment. Using activity-based constants ensures a thermodynamically consistent analysis and prevents misinterpretations, as demonstrated in studies of glycolysis [32].

Q4: Where can I find the software for these frameworks? A4:

- tEFMA: The Java package is available for download at:

https://github.com/mpgerstl/tEFMA[31]. - ETFL: The formulation is available at:

https://github.com/EPFL-LCSB/etfl[30]. - ETGEMs: The method is implemented as a Pyomo framework, and the EcoETM model for E. coli serves as a reference implementation [7].

Frequently Asked Questions (FAQs) and Troubleshooting

FAQ 1: What is the core difference between PTA and traditional constraint-based thermodynamic methods like TMFA?

PTA differs fundamentally by modeling the uncertainty in standard reaction energies and metabolite concentrations with a joint probability distribution, typically a multivariate normal distribution [33]. This approach directly accounts for the correlations between uncertainties of different thermodynamic variables. In contrast, traditional methods like Thermodynamics-based Metabolic Flux Analysis (TMFA) use independent error bounds for each variable, which over-approximates the uncertainty and ignores these correlations [33].

FAQ 2: I am encountering a 'thermodynamically infeasible' error when running Probabilistic Metabolic Optimization (PMO). What are the common causes?

This error indicates that the solver cannot find a set of reaction energies and metabolite concentrations that simultaneously satisfy the steady-state flux constraints and the second law of thermodynamics. Common causes include [33]:

- Structural Inconsistencies in the Model: The metabolic network itself may contain groups of reactions that, given their annotated reversibility, cannot satisfy thermodynamic constraints under any condition. This often involves stoichiometrically equivalent paths that are irreversible in opposite directions, creating infeasible internal cycles.

- Overly Restrictive Flux Bounds: The provided lower and upper flux bounds (

lbandub) may be conflicting with the thermodynamic constraints derived from the probability distribution. - Inaccurate Prior Distributions: The means (

μc,μ°) or covariance matrices (Σc,Σ°) for concentrations and standard reaction energies might not be representative of the biological system under study, leading to a search within an unrealistic thermodynamic space.

FAQ 3: How can I resolve a thermodynamically infeasible internal cycle identified by the structural assessment?

The recommended workflow is [33]:

- Identify the Cycle: Use the structural assessment tool in PTA to enumerate all internal Elementary Flux Modes (EFMs) after blocking exchange, biomass, and ATP maintenance reactions.

- Evaluate Cycle Flux: Determine if the thermodynamically infeasible cycle can carry a non-zero flux under your current simulation constraints.

- Correct the Model: If the cycle can carry flux, you must correct the model's reversibility annotations for the reactions involved in the cycle to resolve the thermodynamic inconsistency. This may require consulting biochemical literature or experimental data.

FAQ 4: What does the 'mode' of the distribution (t*) found by PMO represent?

The vector t* represents the most probable set of values for the log-metabolite concentrations (ln c), standard reaction energies (ΔrG'°), and reaction energies (ΔrG') that are compatible with the network operating at steady-state [33]. It is the point in the high-dimensional steady-state thermodynamic space that has the highest probability, given your prior uncertainty estimates.

Troubleshooting Guide: Common Error Messages

| Error Message | Likely Cause | Recommended Action |

|---|---|---|

| "Thermodynamically infeasible solution" | Structural infeasibility in the model (e.g., infeasible loop) or conflicting flux/energy constraints. | Run the structural assessment tool to identify and correct infeasible internal cycles [33]. |

| "Solver cannot find feasible point" | The joint probability constraints (Eq. 7) and steady-state constraints (Eq. 1) are too tight. | Widen the confidence level α in Eq. 7 or review and adjust the prior distributions (μc, Σc, μ°, Σ°) for plausibility [33]. |

| "Non-positive definite covariance matrix" | The provided covariance matrix for concentrations or standard energies is ill-formed. | Check the construction of your covariance matrices. Ensure they are valid for generating a multivariate normal distribution [33]. |

| "Reaction i has undefined direction" | A reaction that is structurally blocked is still included in the set Γ for thermodynamic analysis. | Remove reactions involving dead-end metabolites from the set Γ of reactions subject to thermodynamic constraints (Eq. 9) [33]. |

Key Experimental Protocols

Protocol 1: Performing Probabilistic Metabolic Optimization (PMO)

Objective: To find the most probable thermodynamic state of the network.

Methodology:

- Define Priors: Define the normal distribution parameters for metabolite concentrations (

μc,Σc) and standard reaction energies (μ°,Σ°) [33]. - Formulate the MIQCP: Set up the Mixed-Integer Quadratically Constrained Program as defined in the PTA framework. The objective function is to minimize

||m||²(which is equivalent to maximizing the probability oft), subject to [33]:- Steady-state mass balance (Eq. 1).

- The quadratic confidence constraint on the thermodynamic variables (Eq. 7).

- The second law of thermodynamics, enforced with integer constraints (Eq. 9).

- Solve: Use a compatible solver (e.g., Gurobi, CPLEX) to compute the solution

m*. - Calculate Mode: Obtain the most probable thermodynamic state via

t* = μt + Q · m*[33].

Protocol 2: Thermodynamic and Flux Sampling (TFS)

Objective: To jointly sample the thermodynamic and flux spaces to explore the network's capabilities.

Methodology:

- Define Constraints: Use the same probabilistic constraints as in PMO (Eq. 1, 7, 9) to define the steady-state thermodynamic space

T[33]. - Sampling Algorithm: Employ a sampling algorithm (e.g., based on Hit-and-Run) that operates within the space defined by the linear (flux bounds), quadratic (thermodynamic confidence), and integer (reaction direction) constraints.

- Generate Samples: Draw a large number of samples for the vector

tand the flux distributionv. - Analyze: Analyze the resulting samples to estimate metabolite concentrations, reaction directions, and flux distributions, noting features like multimodality [34] [33].

Research Reagent Solutions

Table: Essential Components for a PTA Study

| Item | Function in PTA | Notes |

|---|---|---|

| Genome-Scale Metabolic Model | Provides the stoichiometric matrix (S) and initial flux bounds (lb, ub). |

Foundation for all constraints; models like E. coli's iJO1366 are commonly used [33]. |

| Group Contribution Method Estimates | Provides the prior mean (μ°) and covariance (Σ°) for standard Gibbs reaction energies (ΔrG'°). |

Methods like Noor et al. (2013) are used to derive the necessary distributions [33]. |

| Metabolomics Datasets | Informs the prior mean (μc) and covariance (Σc) for log-metabolite concentrations (ln c). |

Used to assume a physiological log-normal distribution for concentrations [33]. |

| PTA Software Package | Implements the PMO and TFS algorithms. | The Python/Matlab package available on GitLab is the reference implementation [34] [33]. |

| MIQCP Solver | Computes the solution to the PMO optimization problem. | Commercial (e.g., Gurobi) or open-source solvers are required [33]. |

Troubleshooting Guide: Common Experimental Issues and Solutions

This guide addresses specific, technical problems you might encounter when working with or implementing models like the EcoETM.

Q1: My model predicts a metabolite as producible, but experiments show no production. The pathway involves carbamoyl-phosphate (Cbp). What could be wrong?

A: This is a classic sign of a thermodynamically infeasible or enzymatically costly pathway being predicted by a standard model. The EcoETM study specifically identified the synthesis pathway of carbamoyl-phosphate (Cbp) in E. coli as being both thermodynamically unfavorable and enzymatically costly, which standard models like iML1515 fail to capture [7].

- Root Cause: Standard stoichiometric models (GEMs) may include pathways that are mathematically possible but physically unrealistic due to energy barriers or unsustainable protein demand.

- Diagnosis Steps:

- Check if your pathway is listed in the EcoETM study as one that was excluded after applying dual constraints. Pathways to L-arginine and orotate, which depend on Cbp, were found to be more realistically predicted by EcoETM [7].

- Use a thermodynamic analysis tool (like OptMDFpathway, detailed below) to calculate the Max-min Driving Force (MDF) for the pathway in question. A low or negative MDF indicates thermodynamic infeasibility [29].

- Solution: Re-evaluate the pathway using a model that incorporates thermodynamic and enzymatic constraints. The EcoETM framework, which uses a Pyomo modeling environment to integrate these constraints, can provide a more realistic prediction by excluding such high-cost pathways [7].

Q2: How can I check if a proposed CO2 fixation pathway in a heterotrophic organism like E. coli is thermodynamically feasible?

A: You can use the OptMDFpathway method to identify pathways with a maximal thermodynamic driving force. This method is formulated as a mixed-integer linear program (MILP) and is applicable to genome-scale models [29].

- Root Cause: CO2 fixation pathways often face significant thermodynamic barriers, making some stoichiometrically possible pathways practically unfeasible.

- Diagnosis Steps:

- Formulate your metabolic network and define the substrate (e.g., glucose, glycerol) and desired product.

- Set constraints for metabolite concentrations (typical range: 0.001 mM to 20 mM) and physiological conditions (pH, temperature) [29].

- Run the OptMDFpathway optimization to find the pathway with the highest MDF value for your substrate-product pair.

- Solution: A positive MDF value indicates a thermodynamically feasible pathway. The study applying this method found that for E. coli, thermodynamically feasible pathways with net CO2 assimilation exist for 145 different cytosolic carbon metabolites when using glycerol as a substrate [29]. Promising products identified include orotate, aspartate, and C4 metabolites of the TCA cycle.

Q3: My model's predictions are inaccurate under specific enzymatic capacity constraints. How can I better integrate enzyme availability?

A: Incorporating enzymatic constraints, specifically using enzyme resource balance constraints, can significantly improve prediction accuracy. The EcoETM model demonstrates that integrating these constraints excludes high enzyme cost pathways that are otherwise predicted by traditional models [7].

- Root Cause: Standard GEMs assume infinite catalytic capacity, ignoring the cellular proteomic budget and leading to predictions of metabolically expensive, and therefore unrealistic, pathways.

- Diagnosis Steps:

- Acquire or estimate enzyme turnover numbers (kcat values) for the reactions in your network.

- Define a constraint for the total cellular protein mass or resource budget available for metabolic enzymes.

- Implement enzyme resource balance constraints in your model, which link reaction fluxes (v) to the required enzyme concentration (E) via the equation: v ≤ kcat * E.

- Solution: Use a modeling framework like the one employed in EcoETM that can simultaneously handle both enzymatic constraints and thermodynamic feasibility within a single platform (e.g., Pyomo) to obtain physiologically more relevant predictions [7].

The workflow below illustrates the diagnostic process for resolving a discrepancy between model predictions and experimental results.

Frequently Asked Questions (FAQs)

Q1: What is the primary advantage of combining enzymatic and thermodynamic constraints in a single model like EcoETM? A: The primary advantage is a significant reduction in the solution space of possible metabolic phenotypes by eliminating pathways that are mathematically possible in standard GEMs but are physically unrealistic. This leads to more accurate predictions of cellular behavior, optimal pathways, and product yields by excluding routes that are either thermodynamically infeasible or would demand an unsustainably high investment of the cell's enzymatic resources [7].

Q2: What does a "Max-min Driving Force (MDF)" value tell me about a metabolic pathway? A: The MDF is a quantitative measure of a pathway's thermodynamic feasibility [29]. It represents the maximum possible value of the smallest thermodynamic driving force ( -ΔG / RT ) across all reactions in the pathway, for any permissible metabolite concentration. A higher MDF indicates a "smoother" thermodynamic profile, facilitating higher flux with lower enzyme requirements. A pathway with a low or negative MDF is thermodynamically constrained and unlikely to carry a significant flux in vivo.

Q3: Are there publicly available databases and tools to help build constrained models? A: Yes, the field relies on several key databases and tools, many of which were used in the development of models like EcoETM and the analyses cited [35] [9]. The table below summarizes essential resources for model reconstruction and analysis.

Table 1: Key Research Reagent Solutions for Metabolic Network Modeling

| Resource Name | Type | Primary Function in Modeling |

|---|---|---|

| BioCyc/MetaCyc [9] | Database | Encyclopedia of experimentally defined pathways, reactions, and enzymes used for draft reconstruction and validation. |

| BRENDA [9] | Database | Comprehensive enzyme database providing functional data, including kinetic parameters (e.g., kcat) needed for enzymatic constraints. |

| BiGG Models [9] | Database | A knowledge base of curated, genome-scale metabolic reconstructions that are chemically and genetically precise. |

| Pathway Tools [9] | Software | A bioinformatics platform that assists in building pathway/genome databases and can generate metabolic models from annotated genomes. |

| ModelSEED [9] | Software | An online resource for the automated reconstruction, analysis, and curation of genome-scale metabolic models. |

| OptMDFpathway [29] | Algorithm/Method | A MILP-based method for identifying metabolic pathways with maximal thermodynamic driving force in genome-scale networks. |

Q4: How can I implement a similar constrained modeling approach for my organism of interest? A: The general workflow involves building upon an existing or new genome-scale metabolic reconstruction. The process for constructing and analyzing a model with multiple constraints is methodical and can be broken down into key stages, as visualized below.

1. Model Reconstruction & Curation: Begin with a high-quality, stoichiometrically and genetically balanced GEM. Use databases like BioCyc and BiGG to gather information on genes, reactions, and metabolites [9]. Tools like Pathway Tools or ModelSEED can help automate draft generation [35] [9].

2. Integrate Thermodynamic Constraints:

- Data Requirement: Collect standard Gibbs free energy (ΔG'°) values for metabolic reactions from literature or estimation software.

- Method Implementation: Incorporate constraints that force the net flux of a reaction to be zero if its calculated Gibbs free energy (ΔG') is positive (infeasible direction). Methods like Thermodynamic FBA or the OptMDFpathway approach can be used to ensure thermodynamic feasibility of the entire flux solution [7] [29].

3. Integrate Enzymatic Constraints:

- Data Requirement: Acquire enzyme turnover numbers (kcat) from databases like BRENDA or use generic values [9].

- Method Implementation: Introduce mass-balance constraints for enzymes, linking reaction flux (vj) to the required amount of enzyme (Ej) via the equation vj ≤ kcatj * Ej. The sum of all enzyme masses (calculated from Ej and molecular weights) is constrained by the total measured or estimated cellular protein mass [7].

4. Simulation & Phenotype Prediction: With the fully constrained model, use optimization techniques (e.g., linear or mixed-integer programming) to simulate growth or product synthesis. The solution will exclude thermodynamically infeasible and enzymatically costly pathways, yielding more realistic and accurate predictions, as demonstrated by the EcoETM case study [7].

Frequently Asked Questions (FAQs)

FAQ 1: Why do my computational models predict metabolite pathways that are biologically infeasible?

Classical stoichiometric algorithms, such as OptForce and FSEOF, often fail to account for thermodynamic feasibility and enzyme-usage costs [36]. This means they can suggest pathways that, while stoichiometrically possible, would not proceed in a real cell because they require energetically unfavorable steps or an unrealistic allocation of cellular resources. To address this, you should use frameworks that systematically incorporate enzyme efficiency and thermodynamic constraints, such as the ET-OptME framework [36].

FAQ 2: How can I identify and remove thermodynamically infeasible internal cycles (loops) from my Flux Balance Analysis (FBA) results?

Standard FBA solutions can contain internal cycles that are thermodynamically infeasible [37]. These are nonzero flux vectors that maintain a steady state but represent a mathematical artifact rather than a real biological process. To eliminate these, you can use Loopless-FBA (ll-FBA), a mixed-integer optimization approach that restricts solutions to loopless flux distributions [37]. While computationally challenging, ll-FBA ensures that predicted fluxes are thermodynamically realistic.

FAQ 3: My model is too large for a full Elementary Flux Mode Analysis (EFMA). How can I find thermodynamically feasible pathways in genome-scale models?

For large, genome-scale models, calculating all Elementary Flux Modes (EFMs) is computationally prohibitive. However, many topologically feasible EFMs are biologically irrelevant [38]. The thermodynamic EFMA (tEFMA) method integrates metabolome data to identify and remove thermodynamically infeasible EFMs during the calculation process. This dramatically reduces the computational runtime and memory consumption, allowing for the analysis of larger networks by focusing only on the feasible subset of pathways [38].

FAQ 4: Is there a method to find the pathway with the highest thermodynamic driving force for a desired product?

Yes, the OptMDFpathway method is designed for this purpose [29]. It is formulated as a Mixed-Integer Linear Program (MILP) to identify pathways with the maximal Max-min Driving Force (MDF). A higher MDF value means all reactions in the pathway can operate with high driving forces simultaneously, facilitating higher flux and lower enzyme requirements. This method can be applied directly to genome-scale models without requiring prior pathway definition [29].

FAQ 5: Can machine learning help predict pathway dynamics without detailed kinetic models?

Traditional kinetic models are difficult to develop due to a lack of reliable enzyme kinetic data [39]. As an alternative, machine learning can be used to learn the function that describes metabolic dynamics directly from time-series multiomics data (e.g., proteomics and metabolomics) [39]. This approach uses the data to predict metabolite time derivatives, effectively creating a dynamic model that can outperform classical kinetic models like Michaelis-Menten, especially as more data becomes available [39].

Troubleshooting Guides

Issue: Model Predictions Do Not Match Experimental Results

| Problem | Potential Cause | Solution | Key References |

|---|---|---|---|

| Biologically Infeasible Pathways | Stoichiometric models ignore thermodynamic constraints, allowing energetically unfavorable steps [36]. | Use methods that integrate thermodynamic constraints, such as ET-OptME or Thermodynamic FBA [36] [37]. | ET-OptME [36] |

| Internal Cycles (Loops) | FBA solutions can include thermodynamically infeasible internal cycles that do not represent net conversion [37]. | Apply Loopless-FBA (ll-FBA) to enforce loopless flux distributions [37]. | Loopless-FBA [37] |

| Low Predictive Accuracy | Models may not account for enzyme kinetics and cellular regulation, leading to incorrect flux predictions [39]. | Integrate machine learning with multiomics data to infer dynamics, or use enzyme-constrained models [39] [36]. | Machine Learning Approach [39] |

Issue: High Computational Cost of Pathway Analysis

| Problem | Potential Cause | Solution | Key References |

|---|---|---|---|

| EFMA is Intractable | The number of Elementary Flux Modes (EFMs) explodes with network size [38]. | Use tEFMA to calculate only the thermodynamically feasible subset of EFMs, drastically reducing the computational load [38]. | tEFMA [38] |

| ll-FBA is Too Slow | Mixed-integer reformulations of ll-FBA are NP-hard and challenging for genome-scale models [37]. | Investigate advanced optimization techniques like combinatorial Benders' decomposition, which has shown promise in solving complex ll-FBA instances [37]. | Loopless-FBA [37] |

Issue: Difficulty in Visualizing and Interpreting Results

| Problem | Potential Cause | Solution | Key References |

|---|---|---|---|

| Complex Networks are Unreadable | Generic network layout algorithms do not incorporate biological knowledge, producing cluttered and unintuitive visualizations [40]. | Use specialized tools like the OptFlux plugin or Cytoscape with SBGN-supported layouts that provide biologically meaningful representations of metabolic networks [40]. | OptFlux Plugin [40] |

Table 1: Performance Comparison of Pathway Prediction Algorithms [36]

| Algorithm | Thermodynamic Constraints | Enzyme Constraints | Reported Increase in Accuracy | Reported Increase in Precision |

|---|---|---|---|---|

| ET-OptME | Yes | Yes | 47-106% vs. other methods | 70-292% vs. other methods |

| Classical Stoichiometric (OptForce, FSEOF) | No | No | Baseline | Baseline |

| Enzyme-Constrained Algorithms | No | Yes | - | - |

| Thermodynamic-Constrained Methods | Yes | No | - | - |

Table 2: Thermodynamic Feasibility in E. coli Central Carbon Metabolism [38]

| Analysis Type | Number of EFMs | Percentage of Total EFMs |

|---|---|---|

| Topologically Feasible EFMs | ~20,000 | 100% |

| Thermodynamically Feasible EFMs (via tEFMA) | ~4,000 | ~20% |

Experimental Protocols

Protocol: Implementing the ET-OptME Framework

Purpose: To incorporate enzyme efficiency and thermodynamic constraints into a genome-scale metabolic model for more physiologically realistic intervention strategies [36].

Workflow:

- Model Preparation: Start with a genome-scale metabolic model (e.g., of Corynebacterium glutamicum).

- Constraint Layering: Integrate the two core algorithms of ET-OptME:

- Apply constraints on enzyme usage cost.

- Apply constraints for thermodynamic feasibility to mitigate bottlenecks.

- Simulation & Analysis: Run the optimized model to predict metabolic engineering targets.

- Validation: Compare the predictions against experimental records for accuracy and precision.

Protocol: Performing Thermodynamic Analysis with OptMDFpathway