Overcoming Protein Constraints in Heterologous Production: A Strategic Guide for Researchers

Heterologous protein production is a cornerstone of modern biotechnology and biopharmaceuticals, yet researchers consistently face constraints that limit yields and protein functionality.

Overcoming Protein Constraints in Heterologous Production: A Strategic Guide for Researchers

Abstract

Heterologous protein production is a cornerstone of modern biotechnology and biopharmaceuticals, yet researchers consistently face constraints that limit yields and protein functionality. This article provides a comprehensive guide for scientists and drug development professionals, exploring the foundational challenges of host burden and toxicity. It details methodological advances in sequence optimization and strain engineering, presents troubleshooting strategies for expression optimization, and offers a comparative analysis of host systems from E. coli to yeast and beyond. By synthesizing current research and emerging technologies like machine learning, this review serves as a strategic roadmap for overcoming production bottlenecks to achieve high-yield, functional recombinant proteins for therapeutic and industrial applications.

Understanding the Core Challenges in Heterologous Protein Production

Heterologous expression, the production of a foreign protein in a host organism, is a cornerstone of modern biotechnology, enabling the manufacturing of biopharmaceuticals, industrial enzymes, and research reagents [1]. However, the introduction and expression of foreign genes place a significant demand on the host's resources. This demand, known as metabolic load, metabolic burden, or metabolic drain, can dramatically alter the host's biochemistry and physiology [2]. This metabolic cost arises because the host cell must divert energy, carbon, nitrogen, and other essential precursors away from its own growth and maintenance to instead transcribe, translate, fold, and secrete the recombinant protein [3]. The consequences are multifaceted, often leading to reduced cell growth, decreased protein yield, and activation of stress responses, which collectively form a major constraint in heterologous production research [2] [3]. Understanding and mitigating this host burden is therefore critical for optimizing the efficiency and productivity of microbial cell factories.

FAQs and Troubleshooting Guides

Frequently Asked Questions

Q1: What are the primary physiological changes in a host experiencing high metabolic burden? A high metabolic burden triggers several physiological changes, including a reduction in growth rate and biomass yield [2] [3]. The host may also exhibit energetic inefficiencies and a shift towards overflow metabolism (e.g., acetate production in E. coli), even under aerobic conditions [3]. On a molecular level, the altered metabolic flux can impact central carbon metabolism, and the stress from protein overproduction can induce the unfolded protein response (UPR) in eukaryotic hosts [1].

Q2: My protein isn't expressing. What should I check first? Your first step should be to verify your DNA construct. Sequence the expression cassette to ensure there are no unintended mutations, stray stop codons, or that your gene of interest is still in-frame, especially if it was cloned via PCR-based methods [4] [5]. Secondly, don't rely solely on SDS-PAGE with Coomassie staining; use a more sensitive method like a western blot or an activity assay to confirm whether low-level expression is occurring [4].

Q3: I see a band on my gel, but my protein isn't functional. Why? A visible band on an SDS-PAGE gel only confirms the presence of the polypeptide chain, not its proper folding. The band could represent insoluble, non-functional protein aggregated into inclusion bodies. To check this, lyse the cells and centrifuge the sample; if your protein is in the pellet, it is insoluble. This often indicates that the protein is folding too quickly or lacks the necessary cellular machinery for proper folding [4].

Q4: How can I reduce the metabolic burden of my recombinant expression system? Several strategies can help alleviate metabolic burden. Using tunable expression systems allows you to balance protein production with cell growth, preventing overburdening [6]. Genome integration of the gene of interest, as opposed to using multi-copy plasmids, eliminates the constant replication burden of the plasmid [1]. Furthermore, engineering the host's central metabolism, for example by overexpressing key glycolytic enzymes, can enhance the flux of carbon and energy toward your product [7].

Q5: What can I do if my protein is insoluble? If your protein is insoluble, first try slowing down the expression process. Lowering the induction temperature (e.g., to 15-20°C) or reducing the inducer concentration can give the cellular folding machinery more time to cope [4] [6]. If that fails, consider co-expressing chaperone proteins like GroEL/GroES or DnaK/DnaJ, which can assist in proper protein folding [4]. Another effective strategy is to fuse your protein to a solubility tag, such as Maltose-Binding Protein (MBP) or thioredoxin [4] [6].

Troubleshooting Common Problems

The following table outlines common issues, their potential causes, and strategic solutions.

Table 1: Troubleshooting Guide for Heterologous Protein Expression

| Problem | Potential Causes | Recommended Solutions |

|---|---|---|

| No Expression | - Errors in construct (mutations, out-of-frame)- Toxic protein/leaky expression- mRNA secondary structure- Rare codons | - Sequence the expression cassette [4] [5]- Use a tighter repression system (e.g., pLysS, T7 lac, lysY strains) [6]- Try a different promoter [4]- Use codon-optimized gene or host with rare tRNAs (e.g., Rosetta strains) [4] [5] |

| Low Yield | - High metabolic burden- Proteolytic degradation- Suboptimal growth conditions | - Use lower-copy plasmid or genome integration [1]- Use protease-deficient host strains (e.g., ompT, lon mutants) [6]- Optimize induction OD, temperature, and inducer concentration [5] |

| Protein Insolubility | - Too-rapid expression- Lack of folding chaperones- Missing disulfide bonds | - Lower induction temperature and inducer concentration [4] [6]- Co-express chaperones [4]- Use engineered strains for disulfide bonds (e.g., SHuffle) or target to periplasm [4] [6] |

| Incorrect Processing | - Inefficient secretion- Hyperglycosylation (in yeast/fungi) | - Optimize signal peptide [7]- Use alternative eukaryotic host (e.g., P. pastoris, filamentous fungi) [8] |

Quantitative Data: Yields and Performance Metrics

To set realistic expectations and benchmark performance, the table below summarizes reported yields for various proteins expressed in different heterologous systems, highlighting the capabilities of advanced fungal platforms.

Table 2: Representative Yields of Heterologous Proteins in Various Host Systems

| Host Organism | Protein Expressed | Yield | Key Optimization Strategy | Reference |

|---|---|---|---|---|

| Aspergillus niger (Chassis AnN2) | Glucose oxidase (AnGoxM) | ~1276 - 1328 U/mL | Multi-copy integration into native high-expression loci | [1] |

| Aspergillus niger (Chassis AnN2) | Pectate lyase (MtPlyA) | ~1627 - 2106 U/mL | Secretory pathway engineering (Cvc2 overexpression boosted yield 18%) | [1] |

| Aspergillus niger (Chassis AnN2) | Triose phosphate isomerase (TPI) | ~1751 - 1907 U/mg | Use of modular donor DNA plasmid with strong native promoter | [1] |

| Aspergillus niger (Chassis AnN2) | Immunomodulatory protein (LZ8) | 110.8 - 416.8 mg/L | Deletion of background protease (PepA) and glucoamylase genes | [1] |

| E. coli (Various strains) | Cellulases | 11.2 - 90 mg/L (purified) | Use of rich growth media and inducible promoters | [9] |

| Trichoderma reesei (Native Producer) | Crude Cellulase Mixture | 14,000 - 19,000 mg/L (crude) | Native high-throughput secretion system; strain engineering | [9] |

Essential Reagents and Research Tools

Selecting the appropriate reagents and host systems is fundamental to experimental success. The following table catalogs key solutions for tackling common challenges in heterologous expression.

Table 3: Research Reagent Solutions for Heterologous Expression

| Reagent / Tool | Function and Application | Example Use Case |

|---|---|---|

| CRISPR/Cas9 System | Enables precise gene editing for strain engineering. | Deletion of multiple copies of endogenous genes (e.g., glucoamylase) in A. niger to reduce background protein secretion [1]. |

| Chaperone Plasmid Sets | Co-expression of chaperone proteins (e.g., GroEL/GroES) to assist with proper protein folding. | Improving the solubility of proteins that are prone to aggregation and inclusion body formation [4]. |

| SHuffle E. coli Strains | Engineered for disulfide bond formation in the cytoplasm. | Functional expression of proteins that require multiple or complex disulfide bonds for activity [10] [6]. |

| Lemo21(DE3) E. coli Strain | Allows tunable expression of the T7 RNA polymerase using L-rhamnose. | Fine-tuning expression levels of proteins that are toxic to the host when expressed at high levels [6]. |

| pMAL Protein Fusion System | Fuses the protein of interest to Maltose-Binding Protein (MBP) to enhance solubility. | Enabling the expression and one-step purification of proteins that are otherwise insoluble [6]. |

| PURExpress In Vitro Kit | A cell-free protein synthesis system that uses recombinant purified components. | Bypassing host toxicity and expressing highly toxic proteins without the constraints of a living cell [6]. |

Core Experimental Protocols and Workflows

Protocol: Constructing a Genetically EngineeredAspergillus nigerChassis Strain

This protocol, adapted from a 2025 study, details the creation of a low-background, high-yield fungal expression chassis [1].

- Objective: To engineer an A. niger chassis strain (AnN2) with reduced endogenous protein secretion and freed-up high-expression loci for heterologous gene integration.

- Materials:

- Industrial A. niger strain AnN1 (with 20 copies of the TeGlaA gene).

- CRISPR/Cas9 plasmid system for A. niger.

- Donor DNA for homologous recombination.

- Protoplast transformation reagents.

- Method:

- Design gRNAs: Design two guide RNAs (gRNAs) targeting the tandemly repeated TeGlaA gene and one gRNA targeting the major extracellular protease gene PepA.

- Prepare Donor DNA: Create a donor DNA cassette containing a selectable marker (e.g., a antibiotic resistance gene) flanked by homology arms complementary to the TeGlaA and PepA loci.

- Co-transformation: Co-transform the CRISPR/Cas9 plasmid and the donor DNA cassette into A. niger AnN1 protoplasts.

- Selection and Screening: Select for transformants on appropriate antibiotic media. Screen colonies using PCR to confirm the deletion of 13 TeGlaA copies and the disruption of the PepA gene.

- Marker Recycling: Use the CRISPR/Cas9 system to excise the selectable marker, resulting in the clean, marker-free chassis strain AnN2.

- Validation: Confirm the phenotype by measuring a ~61% reduction in total extracellular protein and significantly reduced glucoamylase activity compared to the parental AnN1 strain [1].

Protocol: Testing for Protein Solubility

This is a standard method for determining if an expressed recombinant protein is soluble or has formed inclusion bodies [4].

- Objective: To separate and analyze the soluble and insoluble fractions of a cell lysate.

- Materials:

- Induced bacterial culture expressing the protein of interest.

- Lysis buffer.

- Centrifuge.

- SDS-PAGE gel equipment.

- Method:

- Lysate Preparation: Harvest the cells by centrifugation and resuspend in lysis buffer. Lyse the cells thoroughly using sonication or lysozyme treatment.

- Fractionation: Centrifuge the lysate at high speed (e.g., >12,000 x g) for 10-15 minutes.

- Sample Preparation: Carefully collect the supernatant; this is the soluble fraction. Resuspend the pellet in an equal volume of fresh lysis buffer; this is the insoluble fraction.

- Analysis: Analyze both fractions by SDS-PAGE. A band for your protein primarily in the insoluble fraction indicates aggregation and poor solubility.

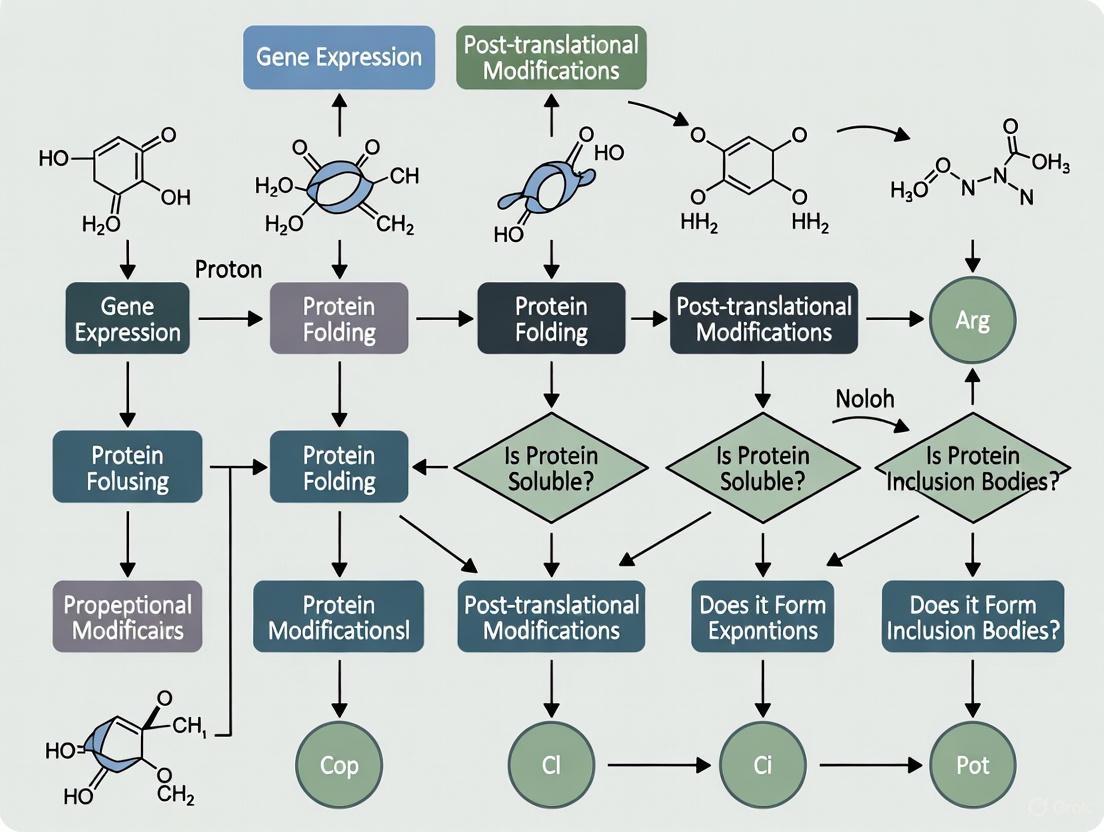

The logical flow of this diagnostic and mitigation process is summarized in the following diagram:

Visualization of Key Concepts

The Protein Secretory Pathway in Filamentous Fungi

The efficient secretion of heterologous proteins in eukaryotic hosts like Aspergillus niger involves a complex, coordinated pathway. Engineering various steps of this pathway is a key strategy for enhancing yield [1] [7].

Metabolic Network Engineering to Reduce Burden

Metabolic burden stems from the reallocation of the host's central metabolic resources. The diagram below illustrates key nodes in the glycolysis and TCA cycle that can be engineered to enhance flux toward heterologous protein production [7].

Troubleshooting Guide: Addressing Protein Toxicity inE. coli

This guide helps diagnose and resolve common issues when producing toxic recombinant proteins in E. coli.

Problem: No Cell Growth or Rapid Culture Collapse After Induction

This indicates severe toxicity where the expressed protein rapidly halts host cell metabolism [11] [12].

| Possible Cause | Diagnostic Experiments | Solution Strategies |

|---|---|---|

| Extreme toxicity of the target protein [12] | Check culture density (OD600) before and after induction. | • Use tightly controlled expression strains (e.g., BL21(DE3)-pLysS) [13] [14].• Switch to a weaker promoter or a promoter induced by a different mechanism (e.g., osmotic shock, temperature shift) [12]. |

| "Leaky" basal expression before induction [13] | Run an uninduced control sample on SDS-PAGE to detect pre-induction protein expression. | • Use strains with plasmid-encoded T7 lysozyme (e.g., pLysS/pLysE), which inhibits T7 RNA polymerase [13] [14].• Add glucose to the growth medium to repress basal expression in T7 systems [12]. |

| Metabolic burden from resource diversion [15] | Monitor growth rate and analyze proteomic changes. | • Optimize induction conditions (cell density, inducer concentration, temperature) [15] [13].• Use richer growth media to provide more resources [15]. |

Problem: Low Yield of Soluble, Active Protein

The protein expresses but is inactive, insoluble, or yields are insufficient [16].

| Possible Cause | Diagnostic Experiments | Solution Strategies |

|---|---|---|

| Aggregation into inclusion bodies [16] | Analyze the soluble and insoluble fractions of cell lysates by SDS-PAGE. | • Reduce induction temperature (e.g., to 25-30°C) [13].• Use fusion tags (e.g., Maltose-Binding Protein, MBP) that enhance solubility [12] [16].• Co-express molecular chaperones to aid folding [17]. |

| Improper protein folding or missing disulfide bonds [17] | Check for activity and use western blot to detect full-length protein. | • Use engineered E. coli strains (e.g., Shuffle T7) with an oxidizing cytoplasm that promotes disulfide bond formation [17].• Target the protein to the periplasm where disulfide bonds form naturally [12]. |

| Host cell toxicity leading to proteolytic degradation or incomplete synthesis [11] | Conduct a time-course experiment to see if the protein degrades over time. | • Use protease-deficient host strains (e.g., BL21).• Shorten the induction time and add protease inhibitors during lysis [16]. |

Frequently Asked Questions (FAQs)

Q1: What are the primary signs that my recombinant protein is toxic to the E. coli host? The main indicators include: severely inhibited cell growth or cell death following induction, a pronounced reduction in final culture density compared to the control, the formation of inclusion bodies for proteins that should be soluble, and the frequent emergence of cells with compensatory mutations that have lost the expression plasmid [11] [15] [12].

Q2: Besides E. coli, what are alternative expression hosts for toxic proteins? No single host is perfect for all toxic proteins, but several alternatives exist:

- Yeast Systems (e.g., Pichia pastoris): Offer the folding machinery of a eukaryote and are generally recognized as safe (GRAS). They can be better suited for producing some eukaryotic toxins [14].

- Baculovirus/Insect Cell Systems: An excellent choice for producing complex eukaryotic proteins that require specific post-translational modifications. They are particularly useful for expressing full-length toxins and immunotoxins [11] [14].

- Mammalian Cell Lines (e.g., CHO, HEK293): Provide the most native environment for expressing human or mammalian toxins, ensuring proper folding, assembly, and activity. However, they are more costly and time-consuming than microbial systems [14].

Q3: How can computational tools help in predicting and mitigating protein toxicity? Advanced computational models like ToxDL 2.0 can predict the potential toxicity of a protein sequence before you even begin lab work. These tools use deep learning to integrate evolutionary, structural, and domain information, helping you identify high-risk motifs in your protein of interest. This allows for the in silico design of deimmunized or less toxic variants by mutating key residues before expression [18].

Q4: My protein is essential but highly toxic. Are there any specialized genetic strategies for its expression? Yes, several strategies are designed specifically for this scenario:

- Use of Weaker Promoters: Avoid strong, constitutive promoters. Use tightly regulated, inducible promoters that allow you to grow the biomass first and induce production later [12].

- Engineering Less Toxic Variants: Identify and mutate the specific amino acid residues responsible for the toxic activity while attempting to retain the protein's structural integrity for study purposes [11].

- Co-expression of Inhibitors: For toxins that inhibit essential host processes (like translation), you can co-express a neutralized version or an inhibitor of the toxin to protect the host until induction [11].

Metabolic Burden and Host Physiology: An Experimental Workflow

Understanding the host's physiological response is key to solving toxicity issues. The following diagram outlines an integrated experimental approach to analyze the impact of recombinant protein production.

Summary of Key Experimental Protocol:

- Culture and Induce: Grow two different E. coli host strains (e.g., M15 and DH5α) in both defined (M9) and complex (LB) media. Induce recombinant protein expression at different growth phases (e.g., early-log phase at OD600 ~0.1 and mid-log phase at OD600 ~0.6) [15].

- Monitor Growth and Expression: Track culture growth (OD600, maximum specific growth rate µmax, dry cell weight) and analyze recombinant protein expression profiles via SDS-PAGE at multiple time points (e.g., mid-log and late-log phase) [15].

- Conduct Proteomic Analysis: Harvest cells from key time points. Perform cell lysis, protein digestion, and Liquid Chromatography-Mass Spectrometry (LC-MS/MS) for Label-Free Quantification (LFQ) proteomics. Compare the proteomes of recombinant cells against control (parental) cells to identify significant changes in protein abundance across different cellular functional categories [15].

- Data Integration: Correlate the proteomic data (changes in transcriptional/translational machinery, stress response proteins) with the observed growth and protein expression parameters. This helps pinpoint the specific metabolic bottlenecks and stress responses caused by the toxic protein [15].

Research Reagent Solutions

The table below lists key reagents and their applications for tackling protein toxicity.

| Research Reagent | Function & Application in Toxicity Mitigation |

|---|---|

| BL21(DE3)-pLysS/E. coli Strain [13] [14] | Host strain; plasmid-encoded T7 lysozyme suppresses basal "leaky" expression of T7 RNA polymerase, essential for toxic gene control. |

| Shuffle T7 E. coli Strain [17] | Engineered host; promotes disulfide bond formation in the cytoplasm, ideal for toxins requiring correct cysteine bridges. |

| Rosetta E. coli Strain | Host strain; supplies tRNAs for rare codons, preventing ribosomal stalling and truncation that can exacerbate toxicity or yield inactive products [12] [13]. |

| pLysS/pLysE Plasmids [13] | Companion plasmids; encode T7 lysozyme for tighter repression in T7 expression systems, can be used in various DE3 strains. |

| Fusion Tags (MBP, GST, SUMO) [12] [16] | Solubility enhancers; fused to the target protein to improve solubility and folding, reducing aggregation and inclusion body formation. |

| Molecular Chaperone Plasmids [17] | Expression vectors; co-express chaperone proteins (e.g., GroEL/GroES, DnaK/DnaJ) to assist in the proper folding of complex or aggregation-prone toxic proteins. |

| ToxDL 2.0 Software [18] | Computational tool; a multimodal deep learning model for predicting protein toxicity from sequence and predicted structure, enabling pre-emptive design. |

Frequently Asked Questions (FAQs)

What are inclusion bodies and why do they form in my protein expression experiments? Inclusion bodies (IBs) are nuclear, cytoplasmic, or periplasmic aggregates of mostly misfolded proteins that lack proper biological function. They form when the rate of recombinant protein expression exceeds the host cell's ability to properly fold the proteins, leading to misfolding where hydrophobic residues normally buried in the native structure become exposed to the aqueous cellular environment. This drives aggregation as these hydrophobic regions interact to shield themselves from water [19]. The aggregation process is primarily driven by these hydrophobic interactions and can be influenced by high expression rates, lack of proper post-translational modification machinery, and specific protein properties [19].

I'm using E. coli as my expression system. Which host strains are recommended to minimize inclusion body formation? The choice of E. coli host strain significantly impacts protein solubility. Strains designed for tight regulation of expression are preferred. For T7-based systems, consider strains that co-express T7 lysozyme (such as lysY or pLysS strains), which inhibits T7 RNA polymerase and reduces basal expression. Additionally, strains lacking proteases (OmpT and Lon) help prevent target protein degradation, and strains carrying the lacIq gene provide enhanced repressor production for tighter control of inducible systems [20]. For proteins requiring disulfide bond formation, specialized strains like SHuffle that allow cytoplasmic disulfide bond formation may be beneficial [20].

What practical steps can I take during my experiment to increase soluble protein yield? Several practical approaches can enhance soluble expression:

- Reduce expression temperature: Inducing protein expression at lower temperatures (15-20°C) slows protein synthesis, allowing more time for proper folding [20].

- Use solubility-enhancing fusion tags: Tags such as Maltose Binding Protein (MBP) can dramatically improve solubility. The pMAL system is one example that facilitates both expression and purification [20].

- Modulate induction conditions: For toxic proteins, use tunable expression systems like the Lemo21(DE3) strain with the rhamnose-inducible PrhaBAD promoter to find the optimal expression level that avoids aggregation [20].

- Consider fusion tag impact: In some cases, commonly used tags like polyhistidine (His-tag) can contribute to insolubility. Testing expression with and without such tags can be beneficial [21].

Are there any sequence-based strategies to prevent aggregation? Yes, optimizing the genetic sequence of your target protein can significantly improve solubility:

- Address mRNA secondary structure: Troublesome secondary structures in the 5' untranslated region, ribosomal binding site, or coding sequence can hinder translation. Altering these sequences, particularly to ensure the ribosomal binding site closely matches the ideal E. coli sequence (AGGAGGT), can help [20].

- Codon optimization: Genes rich in codons corresponding to tRNAs that are low abundance in the host can cause translational stalling. Either co-express rare tRNAs or redesign the gene using host-preferred codons via gene synthesis [20].

- Note of caution: Highly efficient codon optimization can sometimes lead to overly robust expression, creating inclusion bodies. In such cases, pairing optimized sequences with tunable expression systems is recommended [20].

My protein requires disulfide bonds for proper folding. How can I address this in E. coli? Proteins requiring disulfide bonds present a particular challenge in the reducing environment of the E. coli cytoplasm. Strategies include:

- Periplasmic secretion: Using vectors with an N-terminal signal sequence to export the target protein to the oxidative environment of the periplasm, where native Dsb enzymes can catalyze disulfide bond formation [20].

- Engineered cytoplasmic systems: Strains like SHuffle are genetically modified to create a more oxidizing cytoplasm and also express the disulfide bond isomerase DsbC in the cytoplasm, facilitating the correct formation of complex disulfide bonds [20].

- Cell-free systems: Modifying cell-free protein synthesis systems, such as the PURExpress system, by adjusting redox conditions or adding enhancers can also support proper disulfide bond formation [20].

Troubleshooting Guides

Problem: High Basal Expression Leading to Toxicity or Inclusion Bodies

Background: Uninduced expression of the target protein can severely hamper host viability or lead to plasmid loss, often resulting in protein aggregation before controlled induction can even begin [20].

Experimental Protocol:

- Verify the expression system: Ensure your system supplies sufficient LacI repressor protein. Many systems include the

lacIgene on the expression vector. - Switch to a

lacIqhost: Use an expression strain harboring thelacIqgene (e.g., NEB Express Iq). This mutation increases LacI repressor production ten-fold, providing much tighter control [20]. - For T7 systems, employ T7 lysozyme: If using a T7 promoter (e.g., in BL21(DE3)), basal expression from the T7 RNA polymerase is common. Switch to a host that expresses T7 lysozyme (e.g., T7 Express lysY or strains carrying pLysS plasmid), which inhibits T7 RNA polymerase [20].

- Adjust growth medium: For DE3 strains, adding 1% glucose to the medium can decrease basal expression from the lacUV5 promoter by reducing cAMP levels [20].

Problem: Low Solubility of the Target Protein

Background: Some proteins are inherently prone to misfolding and aggregation due to their physicochemical properties, such as large size, multi-domain structure, or stretches of hydrophobic residues [19].

Experimental Protocol:

- First-line approach - lower temperature: Induce expression at a lower temperature (15-20°C). This slows down protein synthesis, giving the cellular folding machinery more time to act [20].

- Use a solubility-enhancing fusion tag: Clone your target gene into a vector that fuses it to a large, highly soluble tag like MBP (Maltose Binding Protein). This can greatly improve the solubility of the fusion partner [20].

- Co-express molecular chaperones: Co-express chaperone systems (e.g., GroEL/GroES or DnaK/DnaJ/GrpE) in the same host. These can assist in the proper folding of the target protein, though note that some target protein may remain complexed with the chaperones and require further separation [20].

- Evaluate fusion tag necessity: Investigate if the purification tag itself is causing insolubility. For example, try expressing the protein without a His-tag, as its removal has been shown to promote the soluble expression of some proteins [21].

Problem: Co-translational Aggregation and Ribosome Stalling

Background: Recent research highlights that aggregation can occur during translation itself ("co-translational"), leading to the sequestration of ribosomal components and mRNAs in amyloid-like inclusion bodies, particularly affecting membrane proteins and those with long-range beta-sheet interactions [22].

Experimental Protocol & Visualization: The diagram below illustrates the mechanism of co-translational aggregation and the ensuing cellular response.

Diagram 1: Mechanism of co-translational aggregation induced by aggregation-prone peptides.

Methodology:

- Detect aggregation: Use super-resolution structured illumination microscopy (SIM) with amyloid-binding dyes like pFTAA (Amytracker) to identify intracellular aggregates with amyloid-like characteristics [22].

- Confirm secondary structure: Employ Atomic Force Microscopy-based Infrared Spectroscopy (AFM-IR) on bacterial sections to analyze the secondary structure of aggregates, specifically looking for a signature peak around 1630 cm⁻¹ indicating high beta-sheet content [22].

- Assess ribosome impact: Monitor activation of the SsrA (tmRNA) ribosome rescue pathway, which is a cellular response to stalled ribosomes, as evidence of co-translational stalling [22].

Table 1: Summary of Key Experimental Findings from Literature

| Experimental Finding | Quantitative/Descriptive Result | Context / System | Source |

|---|---|---|---|

| Non-expression rate in E. coli | Over 20% of >9,000 recombinant proteins failed to express. | Large-scale study (NESG) on diverse proteins in E. coli BL21(DE3) with pET plasmid. | [12] |

| Low expression threshold | Extremely low levels: <0.1 mg per 100 mL of culture medium. | Defined as a critical scenario making subsequent experiments impractical. | [12] |

| His-tag deletion impact | Promoted soluble and highly active expression of uridine phosphorylase and γ-lactamases. | Strategy tested on industrial biocatalysts expressed in E. coli using the pET System. | [21] |

| Antibacterial peptide-induced aggregation | Peptide P33 (from RhtA APR) caused formation of polar inclusion bodies, bactericidal against ESKAPE pathogens. | Induced co-translational aggregation as a broad-spectrum antibacterial mechanism. | [22] |

The Scientist's Toolkit: Key Research Reagent Solutions

Table 2: Essential Materials and Reagents for Addressing Inclusion Body Formation

| Reagent / Tool | Function / Purpose | Example Products / Strains |

|---|---|---|

| Tightly Regulated E. coli Strains | Minimizes basal (uninduced) expression of the toxic target protein, improving cell health and clone stability. | T7 Express lysY, NEB Express Iq, Lemo21(DE3) [20]. |

| Solubility-Enhancing Fusion Tags | Increases the solubility of the fused target protein during expression. | MBP (Maltose Binding Protein) in pMAL system [20]. |

| Chaperone Plasmid Kits | Co-expression of helper proteins (e.g., GroEL, DnaK) that assist in the proper folding of the target protein. | Various commercial chaperone plasmids [20]. |

| Disulfide Bond Engineered Strains | Enables correct formation of disulfide bonds in the E. coli cytoplasm for proteins that require them. | SHuffle strains [20], CyDisCo system [23]. |

| Amyloid-Specific Dyes | Detect and visualize protein aggregates with amyloid-like characteristics in cells. | pFTAA (Amytracker), Thioflavin-T [22]. |

| Tunable Induction Systems | Allows fine control over protein expression levels to find the balance between yield and solubility. | Rhamnose-inducible PrhaBAD promoter in Lemo21(DE3) [20]. |

Heterologous protein production is a cornerstone of modern biotechnology, essential for producing therapeutic enzymes, vaccines, and industrial proteins. However, achieving high yields of functional proteins remains challenging due to molecular bottlenecks that occur at multiple stages: transcription, translation, and post-translational modifications (PTMs). These constraints can drastically reduce protein yield, stability, and biological activity, ultimately impacting research outcomes and commercial viability.

This technical support center provides targeted troubleshooting guides and FAQs to help researchers identify and overcome these critical barriers. The content is framed within the context of systematic approaches for enhancing heterologous protein production, drawing on current advances in genetic engineering, metabolic manipulation, and process optimization.

Troubleshooting Guides & FAQs

Frequently Asked Questions

Q1: I have confirmed that my gene is present in the host, but I detect no protein expression. What are the most common causes?

- A: This common issue can stem from several factors [24] [25]:

- Low Transfection Efficiency: Ensure your transfection protocol is optimized. For stable expression, perform proper selection and use methods that allow examination of individual cells.

- Promoter Strength: The promoter may not be active under your experimental conditions. Consider switching to a stronger or more suitable inducible promoter.

- Detection Method Sensitivity: Your detection protocol (e.g., Western blot) may not be sensitive enough. Optimize your protocol or try a more sensitive method.

- Toxicity of the Protein: Expression of the recombinant protein may be toxic to the host cell, preventing successful colony growth. Using a tightly controlled inducible expression system can help mitigate this.

Q2: My protein is expressed, but it is inactive. What could be wrong?

- A: Expression of a protein does not guarantee functionality [24] [26]:

- Improper Folding: The protein may be misfolded or forming inactive aggregates (inclusion bodies). Consider lowering the induction temperature (e.g., to 30°C) or using a host strain engineered with enhanced chaperone systems.

- Lacking Essential PTMs: Many proteins require specific post-translational modifications (e.g., glycosylation, disulfide bond formation) for activity. Ensure your expression host (e.g., mammalian, insect, or engineered yeast) can perform the necessary modifications that bacterial systems like E. coli typically cannot.

- Truncated Protein: The expressed protein may be truncated due to degradation or premature termination. Check your protein size on an SDS-PAGE gel and verify your plasmid sequence for errors.

Q3: I am working with a fungal expression system like Aspergillus niger, and my protein secretion efficiency is low. What strategies can I use?

- A: Aspergillus niger is a powerful host but faces secretion bottlenecks [7]:

- Secretion Pathway Optimization: Engineer the secretory pathway by overexpressing key components like signal peptides, ER folding chaperones (e.g., BiP), and proteins involved in vesicle trafficking (e.g., SNARE proteins) [7].

- Cell Wall Remodeling: The dense cell wall can trap secreted proteins. Modifying cell wall structure through genetic engineering can facilitate the release of larger proteins [7].

- Signal Peptide Engineering: The native signal peptide of your protein may be inefficient. Screen different natural or engineered signal peptides to find the most efficient one for your protein of interest [7].

Quantitative Data on Common Bottlenecks and Solutions

The table below summarizes key bottlenecks and the efficacy of various strategies based on published research, providing a quick reference for experimental planning.

Table 1: Efficacy of Strategies to Overcome Molecular Bottlenecks

| Bottleneck Category | Specific Challenge | Solution Strategy | Reported Efficacy / Outcome | Key References |

|---|---|---|---|---|

| Transcription | Weak or leaky promoter | Use of strong, inducible promoters (e.g., T7, Tet-On) | Up to 100-fold increase in protein yield | [25] |

| Engineering synthetic promoters | Enables precise spatiotemporal control | [7] | ||

| Translation | Rare codon usage | Host strain engineering (e.g., tRNA supplementation) | Rescues expression of full-length protein | [25] [27] |

| mRNA instability | Codon optimization & 5' GC content adjustment | Improves mRNA half-life & translational efficiency | [25] | |

| Protein Folding & Secretion | Protein misfolding & aggregation | Co-expression of chaperones (e.g., DnaK, BiP); Lowered induction temp | Significant increase in soluble, active protein | [7] [26] [25] |

| Inefficient secretion | Signal peptide engineering; Optimizing ER-Golgi trafficking | Can increase secretion efficiency by over 10-fold | [7] | |

| Disulfide bond formation | Use of SHuffle E. coli or engineered eukaryotic hosts; Optimizing redox | Enabled production of complex antibodies (124 µg/mL IgG) | [28] | |

| Post-Translational Modifications | Lack of glycosylation | Use of eukaryotic hosts (e.g., CHO, P. pastoris) | Essential for therapeutic efficacy & half-life (e.g., EPO) | [26] [27] |

| Methionine oxidation | Media optimization; Use of protective excipients | Preserves anti-elastase activity in α1-antitrypsin | [26] | |

| Deamidation (Asn/Gln) | Control of pH during storage; Formulation optimization | Mitigates loss of bioactivity in IgG1 & Stem Cell Factor | [26] | |

| Host Metabolism | Metabolic burden | Dynamic regulation of central metabolism (e.g., glycolysis, TCA) | Enhanced glycolytic flux & protein yield in A. niger | [7] |

Experimental Protocols for Overcoming Key Bottlenecks

Protocol: Optimizing a CRISPR-Cas System for Multi-Copy Gene Integration inAspergillus niger

Objective: To enhance transcription and gene dosage by integrating multiple copies of a heterologous gene into the genome of A. niger [7].

Materials:

- Aspergillus niger strain susceptible to genetic transformation.

- CRISPR-Cas9 or Cas12 plasmid system optimized for A. niger.

- Donor DNA fragment containing the heterologous gene of interest, flanked by homologous arms targeting a genomic "safe harbor" locus.

- Standard reagents for fungal transformation (e.g., PEG, CaCl₂).

Method:

- Design gRNAs: Design and synthesize guide RNAs (gRNAs) that target specific, non-essential genomic loci suitable for multi-copy integration.

- Prepare Donor DNA: Construct a donor DNA fragment containing your gene of interest, a strong inducible promoter, and a selectable marker.

- Co-transformation: Co-transform the A. niger host strain with the CRISPR-Cas plasmid and the linear donor DNA fragment using protoplast-mediated transformation.

- Selection and Screening: Select transformations on appropriate antibiotic media. Screen resistant colonies via PCR and Southern blotting to confirm multi-copy integration events.

- Expression Validation: Cultivate positive clones and induce expression. Measure transcript levels (qRT-PCR) and protein yield to validate enhanced production.

Protocol: Troubleshooting Protein Solibility and Folding inE. coli

Objective: To recover functional protein from inclusion bodies or prevent their formation [25].

Materials:

- E. coli expression culture (e.g., BL21(DE3) or SHuffle for disulfide bonds).

- IPTG for induction.

- Lysis buffer (e.g., with lysozyme).

- Solubilization buffer (6-8 M Urea or GuHCl).

- Refolding buffer (PBS with reduced denaturant concentration, redox couples like GSH/GSSG).

- SDS-PAGE gel equipment.

Method:

- Test Induction Parameters: Inoculate a small culture and induce at different temperatures (e.g., 18°C, 25°C, 37°C) and IPTG concentrations. Take samples hourly for 4-8 hours.

- Analyze Solubility:

- Pellet 1 mL of induced culture and resuspend in lysis buffer.

- Lyse cells by sonication.

- Centrifuge at high speed to separate soluble (supernatant) and insoluble (pellet) fractions.

- Analyze both fractions by SDS-PAGE.

- If Protein is Insoluble (Inclusion Bodies):

- Solubilize the pellet in 6-8 M Urea.

- Purify the denatured protein under denaturing conditions.

- Refold the protein by slow dialysis or dilution into a refolding buffer.

- If Solubility is Poor, Pre-induction: Use a different host strain (e.g., with chaperone plasmids), change the expression vector, or fuse the protein to a solubility tag (e.g., MBP, GST).

Protocol: Enhancing Thermostability and Pharmacokinetics via PEGylation

Objective: To chemically conjugate polyethylene glycol (PEG) to a therapeutic protein to increase its in vivo half-life, reduce immunogenicity, and improve stability [29].

Materials:

- Purified therapeutic protein.

- Activated PEG derivative (e.g., mPEG-Succinimidyl Carbonate for lysine residues).

- Reaction buffer (e.g., phosphate buffer, pH 8.0-9.0).

- Dialysis membrane or desalting columns.

Method:

- Prepare Protein Solution: Dialyze the purified protein into a suitable reaction buffer (e.g., 50 mM phosphate, 100 mM NaCl, pH 8.5).

- PEGylation Reaction: Add a molar excess of the activated PEG reagent to the protein solution. Gently mix the reaction for several hours at 4°C.

- Quench the Reaction: Stop the reaction by adding a quenching agent like glycine or Tris buffer.

- Purify Conjugate: Separate the PEGylated protein from unreacted PEG and native protein using size-exclusion chromatography or ion-exchange chromatography.

- Characterization: Analyze the conjugate using SDS-PAGE (showing a shift in molecular weight), mass spectrometry, and activity assays to confirm the modification and retained functionality.

Visualization of Bottlenecks and Solutions

The Heterologous Protein Production Cascade

This diagram illustrates the sequential molecular bottlenecks from gene insertion to a functional protein.

Integrated Solutions Workflow

This workflow outlines the multi-strategy approach to overcome the major bottlenecks.

The Scientist's Toolkit: Essential Research Reagents

Table 2: Key Research Reagent Solutions for Heterologous Protein Production

| Reagent / Tool Category | Specific Example | Function & Application | Key References |

|---|---|---|---|

| Advanced Expression Hosts | SHuffle E. coli | Engineered for disulfide bond formation in the cytoplasm; ideal for proteins requiring multiple disulfides. | [28] |

| Pichia pastoris | Eukaryotic host capable of high-density fermentation, secretion, and human-like glycosylation. | [27] | |

| Aspergillus niger | Filamentous fungus; GRAS status; excellent secretor for industrial enzymes and organic acids. | [7] | |

| Genetic Engineering Tools | CRISPR-Cas9/Cas12 Systems | Enables precise gene knock-in, multi-copy integration, and gene repression in fungal and bacterial hosts. | [7] |

| Synthetic Promoters | Engineered for strong, inducible, or tunable control of transcription (e.g., benzoate-activated). | [7] | |

| tRNA Supplementation Plasmids | Provides rare tRNAs to prevent translational stalling and truncation during heterologous expression. | [25] | |

| Folding & Secretion Aids | Chaperone Plasmid Kits | Co-expression plasmids for DnaK/DnaJ/GrpE or GroEL/ES to assist in proper protein folding. | [26] [25] |

| Disulfide Bond Catalysts | Purified DsbC or PDI; added in vitro or co-expressed in vivo to catalyze correct disulfide bond formation. | [28] | |

| PTM Enhancement | Glyco-engineered CHO Cells | Host cells engineered with human glycosyltransferases (e.g., β1,4-GalT, α2,6-SiaT) for human-like glycans. | [26] |

| Cell-Free Protein Synthesis (CFPS) Systems | In vitro system from E. coli, wheat germ, or CHO cells; allows precise control of redox and PTMs. | [28] | |

| Stability & Delivery | PEGylation Reagents | Activated PEG polymers (e.g., mPEG-NHS) for covalent attachment to proteins to enhance half-life. | [29] |

| Formulation Excipients | Sugars, arginine, and other agents used in downstream processing to suppress aggregation and oxidation. | [26] |

The Impact of Gene Source and Sequence Intrinsic Properties

Troubleshooting Guides and FAQs

This technical support center provides targeted guidance for researchers overcoming challenges in heterologous protein production. The following guides address common issues related to gene source and sequence-specific properties that can constrain experimental success and therapeutic development.

Troubleshooting Guide 1: Low Protein Solubility and Yield

Problem: The recombinant protein of interest expresses poorly, forms insoluble inclusion bodies, or yields insufficient quantities for research or development purposes.

Questions & Answers:

Q1: What host-specific factors are critical for improving soluble yield in E. coli? Choosing the correct E. coli host strain is a primary consideration. Strains should be selected to minimize proteolytic degradation and control basal expression. The table below summarizes key host strain features and recommendations [30].

| Host Feature | Function | Recommended Strains/Solutions |

|---|---|---|

| Protease Deficiency | Lacks proteases (e.g., OmpT, Lon) that degrade target proteins. | T7 Express, NEB Express, BL21(DE3) derivatives [30]. |

| Tight Expression Control | Prevents toxic basal expression pre-induction, improving clone stability. | Strains with lacIq gene (increases Lac repressor) or T7 lysozyme (e.g., lysY, pLysS) to inhibit T7 RNA polymerase [30]. |

| Disulfide Bond Formation | Enables correct formation of disulfide bonds in the cytoplasm. | SHuffle strains (oxidizing cytoplasm & disulfide bond isomerase DsbC) [30]. |

| Tunable Expression | Allows fine-tuning of expression level to balance yield and solubility. | Lemo21(DE3) strain using L-rhamnose concentration to modulate expression [30]. |

Q2: Which experimental parameters can be optimized to increase solubility? Several culture and induction conditions can be adjusted to favor proper protein folding [30] [16]:

- Temperature: Inducing protein expression at lower temperatures (15–20°C) often significantly improves yields of properly folded protein.

- Fusion Tags: Fusion partners like Maltose-Binding Protein (MBP) can enhance solubility. Vectors such as the pMAL system are designed for this purpose.

- Chaperone Co-expression: Co-expressing chaperonins like GroEL, DnaK, or ClpB can assist in the proper folding of low-solubility proteins.

Q3: How does the gene source influence the choice of expression system? The intrinsic properties of the protein, dictated by its gene source, determine the required cellular environment for correct folding and function [16].

- Prokaryotic (E. coli) Systems: Ideal for simplicity, speed, and cost-effectiveness. Often unsuitable for complex eukaryotic proteins requiring specific post-translational modifications (e.g., glycosylation).

- Eukaryotic Systems (Yeast, Insect, Mammalian cells): Necessary for proteins requiring disulfide bonds, complex folding, or authentic post-translational modifications. Mammalian cells are the gold standard for producing therapeutic proteins with human-like glycosylation patterns [16].

Troubleshooting Guide 2: Unwanted Cryptic Gene Expression and Toxicity

Problem: The gene of interest is toxic to the host cell, leading to poor host cell growth, genetic instability, plasmid loss, or the expression of unexpected truncated protein products.

Questions & Answers:

Q4: What sequence intrinsic properties can cause toxicity and genetic instability? Unintentional cryptic gene expression is a major cause of toxicity. This occurs when non-native or synthetic DNA sequences introduced into a host are recognized by the host's transcription and translation machinery in unintended ways [31]. This can result in the expression of:

- Truncated peptides or out-of-frame proteins.

- Antisense RNAs that interfere with host genes.

- Burdensome or directly toxic proteins that create strong selection pressure for cells with mutations in your engineered DNA sequence [31].

Q5: What is a "negative design" strategy, and what tools can help? Negative design involves proactively eliminating undesirable sequence features to create more reliable and effective DNA constructs. Instead of just optimizing for high expression, you design to prevent cryptic expression [31].

- Software Tool: CryptKeeper is a pipeline that visualizes predictions of bacterial gene expression signals (promoters, ribosome-binding sites) and estimates the potential translational burden from a DNA sequence.

- Application: It allows researchers to identify and subsequently eliminate unwanted translation initiation sites or promoters before synthesizing a gene, thereby mitigating cloning challenges and experimental failures [31].

Q6: How can codon usage be adapted to manage toxicity? Traditional "codon optimization" that uses only the most frequent codons can lead to excessive expression and toxicity. A more nuanced approach is to design "typical genes" that resemble the codon usage of a specific subset of endogenous host genes (e.g., lowly expressed genes). This strategy can adapt a toxic gene like human α-synuclein for endogenous, low-level expression in yeast, making it possible to work with challenging proteins [32].

Troubleshooting Guide 3: Poor Transfection and Expression in Mammalian Systems

Problem: Low transfection efficiency, high cell toxicity, or undetectable protein expression in mammalian cell cultures.

Questions & Answers:

Q7: What are the common causes of low transfection efficiency and high cell death? The table below outlines frequent causes and their solutions [33] [34].

| Potential Cause | Symptoms | Troubleshooting Solutions |

|---|---|---|

| Poor Cell Health | Low baseline viability, weak adherence. | Use freshly passaged, actively dividing cells. Avoid over-confluent or senescent cultures [34]. |

| Reagent Toxicity | High cell death within 12-24 hours, cell rounding/detachment. | Reduce reagent amount or incubation time. Use low-toxicity, serum-compatible reagents [34]. |

| Incorrect DNA/Reagent Ratio | Low efficiency across all conditions. | Perform a titration experiment to optimize the reagent-to-DNA ratio [34]. |

| Inappropriate Promoter | Low expression in specific cell types. | The CMV promoter can be silenced in some murine cell lines; switch to an alternative promoter like EF-1α [33]. |

Q8: How can I confirm if my protein is being expressed but is simply undetectable?

- Use a Positive Control: Always transfer a control plasmid (e.g., expressing GFP) to verify your transfection protocol is working [33].

- Try a More Sensitive Method: If using Coomassie staining, switch to Western blotting for higher sensitivity. Ensure your primary antibody is specific and validated [33].

- Check Cellular Compartments: For secreted proteins, check both the cellular lysate and the culture medium for the presence of your protein [33].

- Perform a Time-Course: Protein expression over time is protein-dependent. Conduct a pilot time-course assay to find the optimal harvest window [33].

The Scientist's Toolkit: Key Research Reagent Solutions

This table details essential materials and tools used to address the challenges discussed in this guide.

| Item | Function | Key Examples / Notes |

|---|---|---|

| Specialized E. coli Strains | Protein expression with controlled proteolysis, disulfide bond formation, and tight regulation. | SHuffle (disulfide bonds), Lemo21(DE3) (tunable expression), T7 Express lysY (low basal expression) [30]. |

| Cryptic Expression Analysis Tool | Computational prediction of unwanted gene expression signals in DNA constructs. | CryptKeeper software pipeline [31]. |

| "Typical Gene" Design Tool | Designs genes with codon usage resembling a selected subset of host genes (e.g., lowly expressed genes). | Publicly available web-application (e.g., Odysseus) [32]. |

| Solubility Enhancement Tags | Fusion partners that improve solubility and offer a purification handle. | Maltose-Binding Protein (MBP) in the pMAL system [30]. |

| Low-Toxicity Transfection Reagents | Chemical carriers for delivering nucleic acids into sensitive cells, including primary and stem cells. | Lipid-based (e.g., Lipofectamine), Polymer-based (e.g., PEI). Must be selected for cell type and nucleic acid [34]. |

Experimental Workflow and Pathway Diagrams

From Gene Sequence to Functional Protein

This diagram outlines the core experimental workflow for heterologous protein expression and key decision points for troubleshooting.

Mechanisms of Cryptic Gene Expression Toxicity

This diagram illustrates how unintended gene expression arises and impacts the host cell.

Advanced Strategies for Enhanced Protein Expression and Folding

Troubleshooting Guides

Problem 1: Low Heterologous Protein Expression Yield

Potential Causes and Solutions:

Cause A: Suboptimal Codon Usage

- Diagnosis: The codon usage frequency of your gene of interest (GOI) does not match the host's tRNA pool, leading to ribosomal stalling and inefficient translation elongation [35].

- Solution: Implement a context-aware, data-driven codon optimization tool. Avoid solely relying on the Codon Adaptation Index (CAI). Use deep learning frameworks like RiboDecode, which learns from ribosome profiling data to generate sequences that enhance translation, rather than just mimicking host codon bias [36].

- Verification: Compare the predicted translation efficiency (e.g., from RiboDecode's model) of the optimized sequence against the original.

Cause B: Inefficient Translation Initiation

- Diagnosis: A weak or occluded Ribosome Binding Site (RBS) or 5' Untranslated Region (UTR) limits ribosome loading [37].

- Solution: Engineer the 5' UTR. Use pre-validated UTR backbones from highly expressed genes or viruses [38] [39]. For fine-tuning, employ RBS calculators or build 5' UTR libraries to systematically vary translation initiation rates over a 100,000-fold range [37].

- Verification: Measure mRNA levels and protein output. A strong increase in protein with minimal change in mRNA levels confirms improved translation initiation.

Cause C: Poor mRNA Stability

- Diagnosis: The mRNA is rapidly degraded in the host cell, reducing the time available for translation.

- Solution: Incorporate stabilizing elements. Use 3' UTRs from stable mRNAs (e.g., human HBB) or viral RNAs (e.g., MALAT1 ENE) [39]. For the coding sequence, optimize for in-cell stability; highly structured "superfolder" mRNAs can improve both stability and expression [39].

- Verification: Perform an mRNA decay time-course experiment to measure the half-life of your transcript.

Problem 2: Protein Misfolding or Loss of Function

Potential Causes and Solutions:

Cause A: Disruption of Co-Translational Folding

- Diagnosis: Over-optimization for speed, using only the most common codons, can cause ribosomes to move too rapidly and disrupt the precise folding kinetics of the protein [35].

- Solution: Use an optimization tool that preserves functionally important rare codon clusters, especially those known to pause ribosomes at critical folding junctures. Tools like DeepCodon integrate strategies to maintain these conserved rare codons [40].

- Verification: Assess protein activity and solubility. Compare the functionality of the protein expressed from a fully optimized sequence versus one that conserves rare codon clusters.

Cause B: Altered Splicing or Regulatory Motifs

- Diagnosis: Synonymous codon changes can inadvertently create cryptic splice sites, miRNA binding sites, or other regulatory motifs.

- Solution: After in silico optimization, screen the sequence for the accidental creation of these motifs. Use sequence analysis tools to check for off-target regulatory sequences.

- Verification: If possible, check the mRNA product in the host for correct splicing and size.

Problem 3: Inconsistent Performance Across Different Systems

Potential Causes and Solutions:

- Cause: Lack of Cellular Context Consideration

- Diagnosis: An mRNA sequence optimized using a standard, context-free algorithm may not perform well in your specific cell line or tissue type due to differences in tRNA abundance and other cellular machinery [36] [35].

- Solution: Employ context-aware optimization tools. RiboDecode, for instance, can incorporate gene expression profiles from RNA-seq to account for the specific cellular environment, improving performance across different cell lines and for different mRNA formats (unmodified, modified, circular) [36].

- Verification: Validate protein expression in your specific target cell line or tissue, not just in a standard model organism.

Frequently Asked Questions (FAQs)

Q1: What is the most critical factor for maximizing protein expression: codon optimization or UTR engineering? A: While both are crucial, recent high-throughput studies suggest that in-cell mRNA stability is a greater driver of protein output than high ribosome load alone [39]. This means that designing an mRNA with a stable structure (including optimized UTRs and CDS) can be more impactful than only maximizing theoretical translation initiation rates. An integrated approach that optimizes both stability and translation is most effective.

Q2: My codon-optimized gene has a high CAI, but protein expression is still low. Why? A: A high CAI indicates that your sequence uses codons common in highly expressed host genes, but it is a simplistic metric. Low expression can persist due to:

- mRNA Structure: The optimized sequence may have formed stable secondary structures that hide the RBS or start codon [41].

- tRNA Availability: CAI does not fully account for the actual, dynamic availability of tRNAs in your specific host and growth conditions [35].

- Context-Specific Effects: The sequence may be optimal in a general sense but not for your specific cellular context. Shift to tools that use deep learning on empirical data like ribosome profiling (RiboDecode) [36] or that model tRNA competition more accurately.

Q3: How can I design an mRNA sequence that is both highly stable and efficiently translated? A: This was historically challenging due to a perceived trade-off, but it is achievable by:

- Selecting Stabilizing UTRs: Use 5' and 3' UTRs from genes with known high stability (e.g., viral UTRs, human HBB) [39].

- Designing a "Superfolder" CDS: Use platforms like Eterna and models like DegScore to design coding sequences with optimized secondary structures that resist degradation and remain translatable [39].

- Leveraging Nucleoside Modifications: Incorporation of pseudouridine (ψ) can further enhance both the stability and translational capacity of the mRNA [39].

Q4: Can I use codon optimization to control the subcellular localization or timing of protein expression? A: Emerging research suggests yes, through tissue-specific codon optimization. Since tRNA pools can vary between tissues, an mRNA can be optimized to be translated more efficiently in one tissue than another [35]. This is a nascent but promising area for targeted gene therapy.

Experimental Protocols & Data

Protocol 1: Systematic mRNA Optimization using PERSIST-seq

This protocol outlines a high-throughput method for evaluating mRNA designs [39].

- Library Design: Synthesize a DNA library containing your GOI with diverse combinations of 5' UTRs, codon-optimized CDS, and 3' UTRs. Include unique barcodes in the 3' UTR for each variant.

- In Vitro Transcription (IVT): Perform pooled IVT on the library to generate a diverse mRNA pool. Co-transcriptionally add a 5' cap and a 3' poly(A) tail.

- Transfection & Harvest: Transfert the mRNA library into your target cells. Harvest cells at multiple time points.

- Polysome Profiling: Fractionate cell lysates on a sucrose gradient to separate mRNAs based on ribosome load. Sequence the barcodes in each fraction.

- Stability Analysis: Extract total RNA from harvested cells and sequence barcodes to track the abundance of each mRNA variant over time (in-cell stability). Incubate the mRNA pool in a solution mimicking physiological conditions and sequence over time to assess in-solution stability.

- Data Integration: Model protein output based on ribosome load and in-cell stability measurements to identify top-performing constructs.

Protocol 2: Validating RBS/UTR Strength with a Reporter System

- Clone UTR Library: Fuse a library of diverse 5' UTR sequences upstream of a reporter gene (e.g., GFP, luciferase) in your expression vector.

- Transform & Culture: Introduce the plasmid library into your host organism and grow under selective conditions.

- Measure Output: Use flow cytometry (for fluorescent reporters) or enzymatic assays to quantify protein expression for each variant.

- Correlate with Sequence: Sequence the UTR region of clones with high, medium, and low expression to identify optimal sequence features.

Table 1: Performance Comparison of Codon Optimization Tools

| Tool Name | Underlying Approach | Key Feature | Validated Improvement |

|---|---|---|---|

| RiboDecode [36] | Deep Learning (on Ribo-seq data) | Context-aware, generative design | - 10x stronger neutralizing antibodies (in vivo).- Equivalent efficacy at 1/5th mRNA dose (in vivo). |

| DeepCodon [40] | Deep Learning (on natural sequences) | Preserves critical rare codons | Outperformed traditional methods in 9/20 experimental tests. |

| LinearDesign [36] | Linear Programming | Jointly optimizes CAI and MFE | Superior in silico performance over earlier methods. |

Table 2: Key UTR Elements for Expression Optimization

| UTR Element | Type | Function and Application | Key Consideration |

|---|---|---|---|

| AU-rich elements [37] | 5' UTR | Stabilizes mRNA via S1/Hfq proteins, enhancing protein production. | Long AU-rich tracts may increase accessibility to RNases. |

| RG4 Structures [37] | 5' or 3' UTR | Acts as an internal ribosome entry site in 5' UTR; enhances stability in 3' UTR. | Strong structures may potentially inhibit scanning. |

| Synthetic Dual UTRs [37] | 5' & 3' UTR | Concatenated UTRs that enhance both transcription and translation. | Requires screening of large randomized libraries for identification. |

| Viral UTRs (e.g., DENV, TMV) [39] | 5' & 3' UTR | Hijacks host translation machinery for high expression and stability. | May trigger stronger immune responses; requires testing. |

The Scientist's Toolkit: Research Reagent Solutions

Table 3: Essential Reagents and Resources for Cis-Optimization

| Item | Function | Example / Source |

|---|---|---|

| Pre-validated UTR Backbones | Provides a reliable starting point for mRNA design, improving translation efficiency and stability. | Aldevron Blog [38] |

| Ribo-seq Dataset | Provides genome-wide data on ribosome positions, enabling data-driven codon optimization. | Used to train RiboDecode [36] |

| UTR Library Kits | Allows for high-throughput experimental screening of UTR variants to fine-tune expression levels. | Commercially available or custom-built via synthesis [37] |

| In vitro Transcription Kit | For synthesizing mRNA transcripts for validation experiments. | Various commercial suppliers. |

| Pseudouridine (ψ) | A nucleoside modification that decreases immunogenicity and can enhance both stability and translation of mRNA. | Used in PERSIST-seq study [39] |

Workflow and Relationship Visualizations

mRNA Optimization Framework

Key Optimization Factor Relationships

Frequently Asked Questions (FAQs)

1. My protein is toxic to the cells, resulting in no growth after transformation. What can I do? Protein toxicity is a frequent challenge that can inhibit growth or cause cell death [12]. To address this, use expression strains with tighter regulation. For T7-based systems, BL21 (DE3) pLysS or BL21 (DE3) pLysE strains are recommended, as they contain T7 lysozyme inhibitors that suppress basal expression [12] [42]. The BL21-AI strain, which uses arabinose for induction, provides an alternative, tightly-regulated system [42]. Furthermore, you can supplement your growth medium with 0.1-1% glucose to repress basal expression before induction [42].

2. I get good transformation but no protein expression. What are the common causes? This issue can stem from several factors [43]:

- Genetic Sequence: Verify your DNA sequence for frame-shifts or premature stop codons [42].

- Codon Usage: Check for the presence of rare codons that can stall translation. The arginine codons AGG and AGA, for example, are used infrequently in E. coli and can be replaced with more common synonyms [12] [42].

- Plasmid Instability: If using ampicillin resistance, the antibiotic can degrade during culture. Using carbenicillin or a fresh antibiotic dose can help maintain selection pressure [42]. Always use freshly transformed cells for expression experiments.

- Incorrect Assumption: The protein may be expressed but located in the insoluble fraction (inclusion bodies). Always analyze both the soluble and insoluble fractions of the cell lysate [42].

3. My target protein is expressed but entirely in inclusion bodies. How can I improve solubility? Strategies to enhance solubility focus on slowing protein production to allow proper folding [44] [42]:

- Lower Induction Temperature: Reduce the temperature to 30°C, 25°C, or even 18°C after induction. Lower temperatures typically require longer induction times (e.g., overnight at 18°C) [42].

- Reduce Inducer Concentration: Use lower amounts of IPTG (e.g., 0.1 - 1 mM) to moderate expression levels [42].

- Use a Weaker Promoter or Low-Copy Plasmid: This reduces the number of gene copies and the overall expression burden.

- Co-express Chaperones: Use engineered E. coli strains that co-express molecular chaperones like GroEL-GroES or DnaK-DnaJ to assist with protein folding [44] [17].

4. I see multiple protein bands or degradation on my gel. What is happening and how can I prevent it? A single dominant smaller band suggests premature translation termination, often due to codon usage bias, while a ladder of bands typically indicates proteolytic degradation [42]. To prevent degradation:

- Use Protease Inhibitors: Add protease inhibitors like PMSF to your lysis buffer. Note that PMSF is unstable in aqueous solution and should be used fresh [42].

- Perform a Time-Course Experiment: Determine the optimal harvest time by analyzing expression levels at different time points post-induction to avoid prolonged exposure to proteases [42].

- Use Specialized Strains: Consider using protease-deficient host strains (e.g., BL21) to minimize degradation.

Troubleshooting Guides

Guide 1: Overcoming Protein Toxicity and Basal Expression

Problem: The target recombinant protein disrupts the host's normal physiology, leading to inhibited growth or cell death, often due to leaky expression before induction.

Solution Strategy: Implement tighter regulation of expression and consider genetic modifications.

Experimental Protocol:

- Transformation: Clone your gene into a tightly regulated vector (e.g., pET series with T7 promoter, pBAD with arabinose promoter). Transform into a restrictive host like BL21 (DE3) pLysS or BL21-AI [12] [42].

- Plating: Plate transformed cells on LB plates containing the appropriate antibiotic and 0.1-1% glucose. Glucose helps repress basal expression in both T7-lac and pBAD systems [42].

- Culture Growth: Inoculate a primary culture from a fresh colony and grow overnight.

- Expression Induction: Sub-culture the overnight culture into fresh medium. For BL21 (DE3) strains, induce with a low concentration of IPTG (e.g., 0.1 mM) when OD600 reaches ~0.4-0.6. For BL21-AI, induce with L-arabinose (e.g., 0.2%) [42].

- Evaluation: Monitor cell growth post-induction and analyze protein expression via SDS-PAGE.

The following workflow outlines the decision path for addressing toxic protein expression:

Guide 2: Strategies for Enhancing Protein Solubility

Problem: The target protein is expressed but aggregates into insoluble inclusion bodies.

Solution Strategy: Modulate expression conditions and leverage host cell folding machinery to favor correct protein folding.

Experimental Protocol:

- Temperature Screening: Test induction at a range of temperatures (e.g., 37°C, 30°C, 25°C, 18°C). Induce cultures at the target OD600 and continue incubation for 3-4 hours (30°C) or overnight (18°C) [42].

- Inducer Titration: Induce parallel cultures with different IPTG concentrations (e.g., 1.0, 0.5, 0.1 mM) to find the level that minimizes aggregation.

- Chaperone Co-expression: Transform your plasmid into a compatible chaperone plasmid strain (e.g., strains expressing GroEL/ES or Trigger Factor) or include chaperone plasmids in your experiment [44] [17].

- Solubility Analysis: a. Harvest cells by centrifugation. b. Lyse cells using sonication or lysozyme treatment in a suitable buffer. c. Separate the soluble (supernatant) and insoluble (pellet) fractions by centrifugation at >12,000 x g for 10-15 minutes. d. Analyze both fractions by SDS-PAGE to assess solubility.

The table below summarizes key optimization parameters and their effects:

Table 1: Optimization Strategies for Improving Recombinant Protein Solubility

| Parameter | Optimization Strategy | Mechanism of Action | Considerations |

|---|---|---|---|

| Temperature | Lower induction temperature (18-25°C) | Slows translation rate, allowing more time for proper folding | Requires longer induction time (e.g., overnight) [42] |

| Inducer Concentration | Use lower IPTG (0.1 - 0.5 mM) | Reduces transcription/translation burden, minimizing aggregation | May require titration to find optimal level for specific protein [42] |

| Fusion Tags | Use solubility-enhancing tags (e.g., MBP, GST, SUMO) | Acts as a solubility chaperone; can improve folding and yield | May require cleavage and removal for final protein product [44] [12] |

| Chaperone Co-expression | Co-express GroEL/ES, DnaK/DnaJ, etc. | Directly assists in the folding of nascent polypeptides | Requires specialized strains or additional plasmids [44] [17] |

| Media/Cofactors | Use minimal media (e.g., M9); add essential cofactors | Reduces metabolic burden; ensures availability of essential ions/molecules | Can lower overall biomass but increase functional protein yield [42] |

The Scientist's Toolkit: Key Research Reagents

Table 2: Essential Reagents and Strains for Bacterial Trans-Optimization

| Reagent / Material | Function / Purpose | Examples & Notes |

|---|---|---|

| Specialized E. coli Strains | Engineered hosts to address specific challenges like toxicity, disulfide bonds, or difficult codons. | BL21(DE3) pLysS/pLysE: For toxic proteins; suppresses basal expression [12] [42].Origami B: Enhances disulfide bond formation in the cytoplasm [17].Rosetta: Supplies tRNAs for rare codons (AGA, AGG, AUA, CUA, GGA) [12]. |

| Expression Vectors | Plasmids designed for controlled gene expression. | pET series: High-expression, T7 promoter, IPTG-inducible [12].pBAD series: Tightly regulated by arabinose, useful for toxic genes [42]. |

| Fusion Tags | Polypeptide sequences fused to the target protein to aid expression, solubility, or purification. | His-tag: Simplifies purification via immobilized metal affinity chromatography (IMAC).MBP, GST, SUMO: Enhance solubility; can be cleaved off post-purification [44] [12]. |

| Inducers | Chemical molecules that trigger transcription of the target gene. | IPTG: Non-metabolizable inducer for lac/T7-lac promoters [42].L-Arabinose: Inducer for the pBAD promoter system [42]. |

| Protease Inhibitors | Chemicals that inhibit proteolytic enzymes, preventing target protein degradation. | PMSF: Serine protease inhibitor (short half-life in water) [42].Commercial Cocktails: Broad-spectrum inhibitors targeting multiple protease classes. |

Advanced Engineering: Pathway Optimization for Complex Production

Problem: For metabolic engineering beyond single protein production, low yield arises from carbon loss in competing pathways and insufficient supply of key cofactors.

Solution Strategy: Rationally rewire central carbon metabolism using a "host-aware" framework to maximize flux toward the desired product.

Experimental Protocol (Conceptual Workflow for Pathway Engineering):

- Identify Key Nodes: Map the biosynthetic pathway and identify branch points where carbon is diverted (e.g., α-ketoglutarate in the TCA cycle for T-4-HYP production) [45].

- Knock Out Competing Pathways: Use gene knockout techniques (e.g., CRISPR-Cas9, λ-Red recombination) to delete genes encoding enzymes in competing metabolic shunts [45].

- Enhance Precursor Supply: Introduce heterologous pathways to minimize carbon loss. For example, the Non-Oxidative Glycolysis (NOG) pathway can redirect glucose to acetyl-CoA with higher efficiency [45].

- Balance Cofactor Supply: Overexpress enzymes or introduce transhydrogenases to balance cofactors (e.g., increase NADPH supply for reductive biosynthesis) [45].

- Implement Dynamic Control: Engineer genetic circuits that decouple growth from production, allowing cells to first build biomass before switching to a high-production state [46].

- Fed-Batch Fermentation Optimization: In a bioreactor, use continuous feeding of carbon source and key nutrients (e.g., Fe²⁺ for hydroxylases) while controlling dissolved oxygen to support high-density production [45].

The following diagram visualizes this systematic engineering approach:

Core Concepts and Quantitative Foundations

In heterologous protein production, the design of your vector system is a critical determinant of success. Precise control over plasmid copy number (PCN) allows researchers to directly influence gene dosage, thereby optimizing protein expression levels and mitigating host cell metabolic burden [47]. A foundational understanding of these elements is essential for overcoming protein production constraints.

Table 1: Common Origins of Replication and Their Characteristics [48]

| Origin of Replication | Example Vectors | Typical Copy Number (per cell) | Incompatibility Group | Replication Control |

|---|---|---|---|---|

| pUC (pMB1 derivative) | pUC series | 500 - 700 | A | Relaxed |

| pMB1 / ColE1 | pBR322, pET, pGEX | 15 - 20 | A | Relaxed |

| p15A | pACYC | ~10 | B | Relaxed |

| CloDF13 | pCDF | 20 - 40 | D | Relaxed |

| pSC101 | pSC101 | ~5 | C | Stringent |

The following diagram illustrates the fundamental mechanism of copy number control for ColE1-like origins, which form the basis for many common cloning vectors.

Diagram 1: ColE1 replication control mechanism.

Troubleshooting Guides and FAQs

FAQ 1: How do I choose the right plasmid copy number for my experiment?

Selecting the appropriate copy number involves balancing gene dosage with metabolic burden. Key considerations include [47] [48]:

- Protein Properties: For toxic proteins, use low- or medium-copy vectors (e.g., pBR322, pACYC) to prevent host growth inhibition. For high-yield expression of non-toxic proteins, high-copy vectors (e.g., pUC) are preferable.

- Host Strain: The genetic background of your E. coli strain can affect PCN;

endA-strains are recommended for high plasmid yields [48]. - Plasmid Incompatibility: When co-expressing multiple plasmids, ensure they have compatible origins from different incompatibility groups (e.g., Group A pBR322 and Group B pACYC) to maintain stability [48].

FAQ 2: My protein yield is low despite using a high-copy number plasmid. What could be wrong?

This common issue often stems from metabolic burden or protein toxicity. High-copy plasmids can overburden the host, diverting resources away from growth and protein synthesis [47].

Troubleshooting Steps:

- Reduce Metabolic Burden: Switch to a medium- or low-copy number plasmid. The relationship between PCN and growth rate is quantifiable; one study found that each plasmid imposes an additional 0.063% metabolic burden on the host [47].

- Induce at Lower Cell Density: For toxic proteins, induce expression when the culture is in mid-log phase to maximize the number of productive cells before stress impacts yield.

- Use a Tunable System: Employ a plasmid with a tunable copy number (e.g., aTc-inducible priming RNA promoter) [47]. This allows you to start with a low PCN for robust growth, then induce a high PCN for production, optimizing the balance.

FAQ 3: How can I control plasmid copy number dynamically?

Advanced systems now allow for fine-tuned, inducible control of PCN, moving beyond static origins. The table below summarizes key quantitative findings from recent research on tunable systems.

Table 2: Performance of Tunable Plasmid Copy Number Systems [47] [49]

| Control Strategy | Inducer | Plasmid Backbone | Dynamic Range (Copies/Cell) | Key Application/Outcome |

|---|---|---|---|---|

| Inducible priming RNA (RNA-p) promoter | aTc | pUC19 | 1.4 to ~50 | Optimization of violacein pigment production. |

| Inducible inhibitory RNA (RNA-i) | IPTG | pUC19 | ~30 to ~270 | Demonstrated high PCN can correlate with faster growth. |

| Regulation of essential gene (infA) on plasmid | aTc | CloDF13 | 22-fold range | 5.3-fold increase in itaconic acid titer (3 g/L). |

FAQ 4: How can I maintain plasmids without antibiotics, and how does this affect copy number?

Antibiotic-free systems are safer and avoid issues of resistance. One effective method is essential gene complementation, where an essential gene (e.g., infA, encoding translation initiation factor IF-1) is deleted from the host chromosome and placed on the plasmid [49].

Consideration: In these systems, the expression level of the essential gene is inversely correlated with PCN. Lower expression of the essential gene leads to higher copy numbers, and vice versa [49]. This relationship can be leveraged for dynamic control, as shown in the experimental protocol below.

Experimental Protocols